Conveying frame applied to logistics stacking machine

一种输送架、物流码的技术,应用在输送架领域,能够解决转动角度和工作空间限制、机械手运行不够稳定、不够整齐等问题,达到不易滑脱、性能稳定可靠、工作效率高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings of the description:

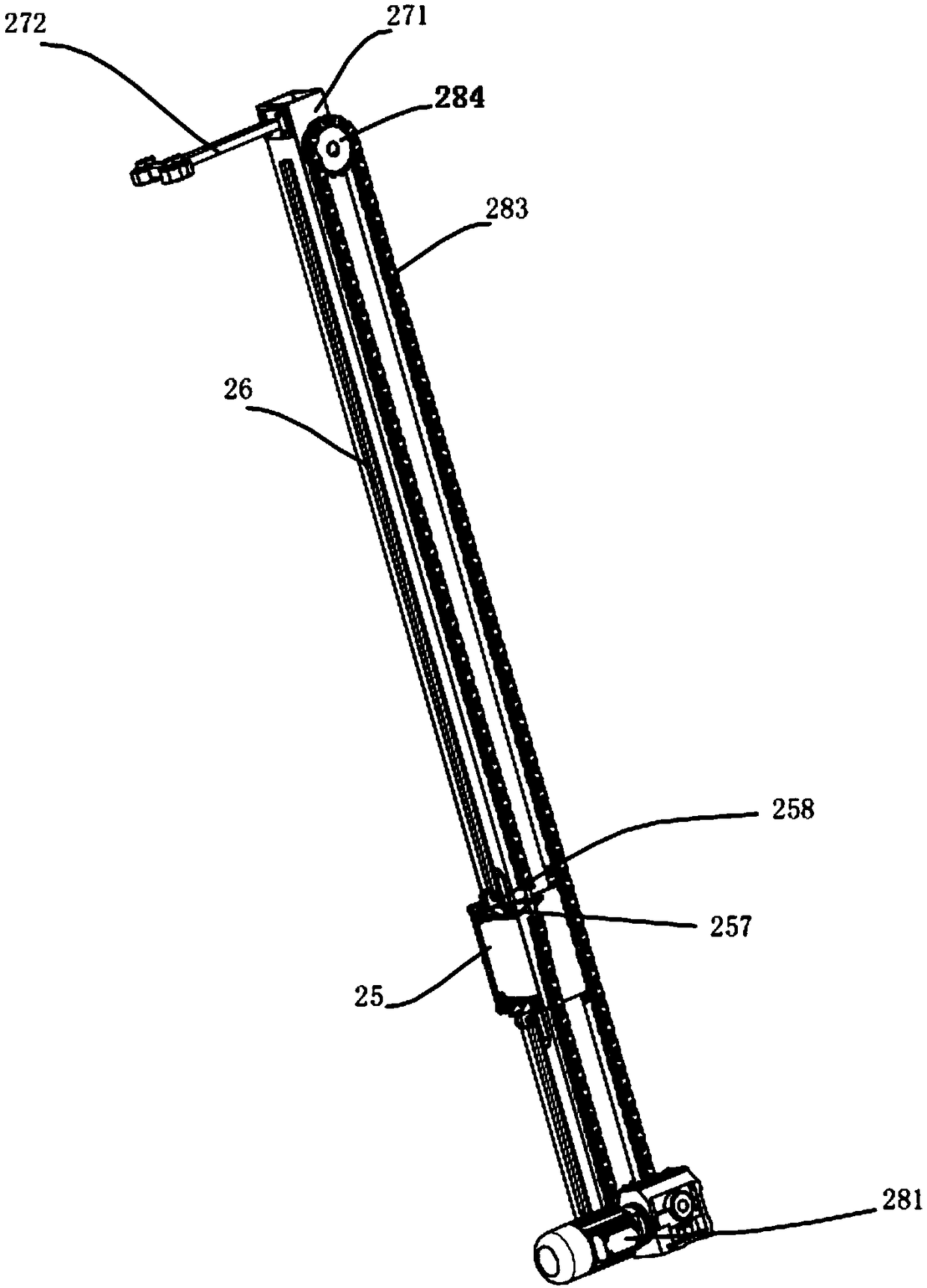

[0036] As shown in Figures 1 to 13, the present invention proposes a specific embodiment of a conveyor frame applied to a logistics palletizer, as shown in Figure 6, the conveyor frame applied to a logistics palletizer includes a lateral movement drive of a cargo conveyor device, the up and down movement driving device of the cargo conveying platform, the limit sensor 258 and the PLC controller, and the limit sensor 258 is connected with the PLC controller;

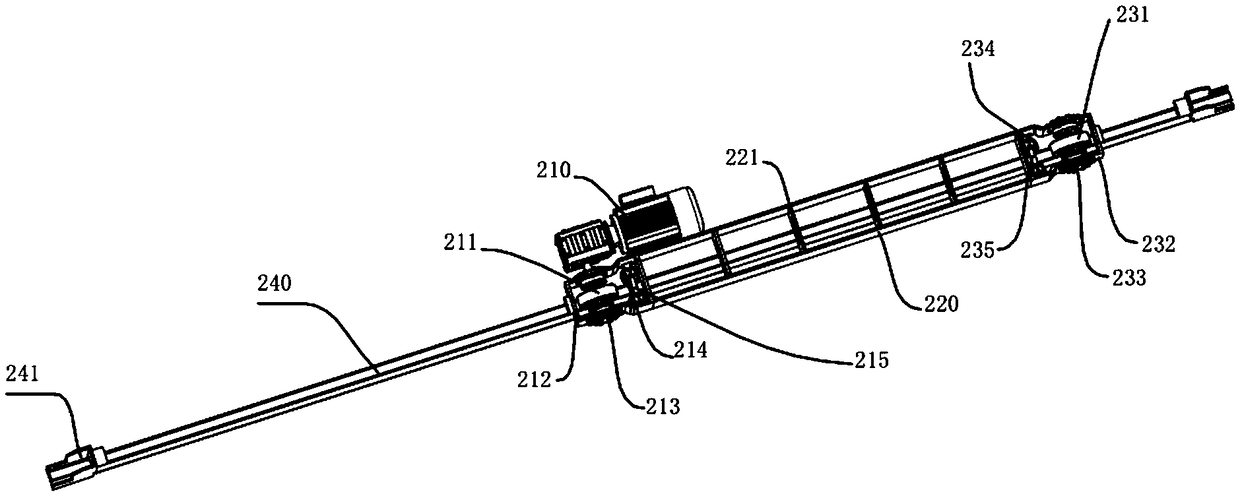

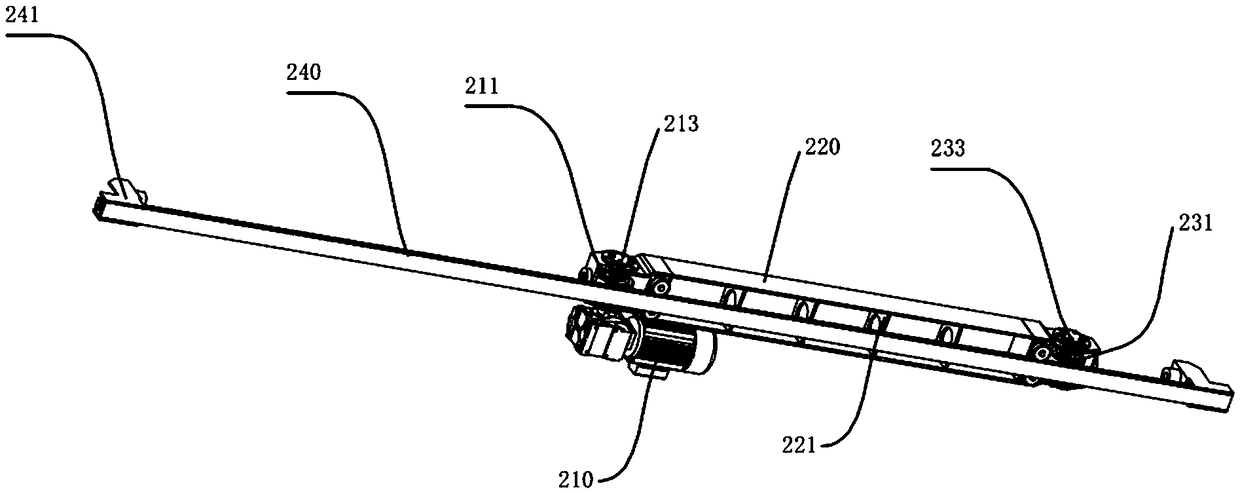

[0037]As shown in Fig. 1, Fig. 2, Fig. 10 and Fig. 11, the lateral movement driving device of the cargo conveying platform includes a transverse slide rail 240, a first servo motor 210, a first frame 212, a bracket 220, and a second frame 232 , the driving roller 211 and the driven roller 231; the baffle 241 used to limit the effective sliding stroke of the driving roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com