Bottled medicine production line buffer equipment

A cushioning equipment and production line technology, applied in the types of packaging items, packaging, transportation and packaging, etc., can solve the problems of broken tablets, shaking of bottles, and mutual collisions, so as to prevent collisions, avoid losses, and reduce collisions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

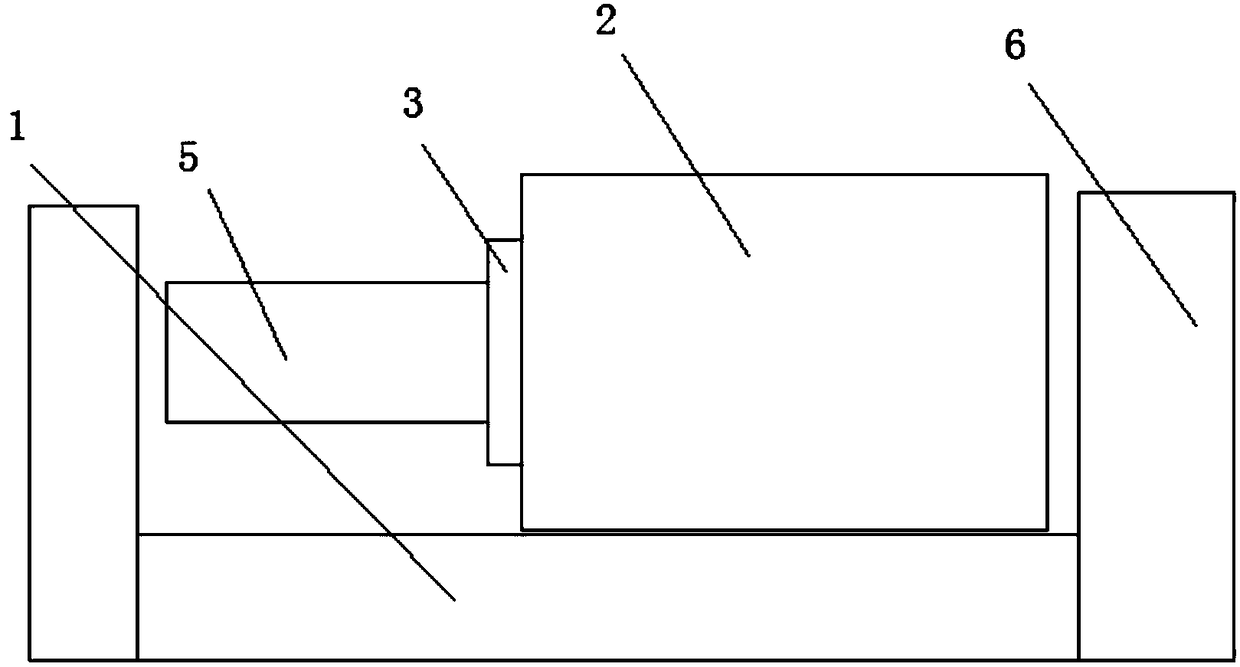

[0020] like Figure 1 to Figure 5 As shown, a bottled medicine production line buffer equipment, including a base 1, the base 1 is provided with a buffer device 2, the front end of the buffer device 2 is provided with a bearing 5, and the connection between the bearing 5 and the buffer device 2 is provided with a seal The washer 3 is provided with guard plates 6 around the base 1 .

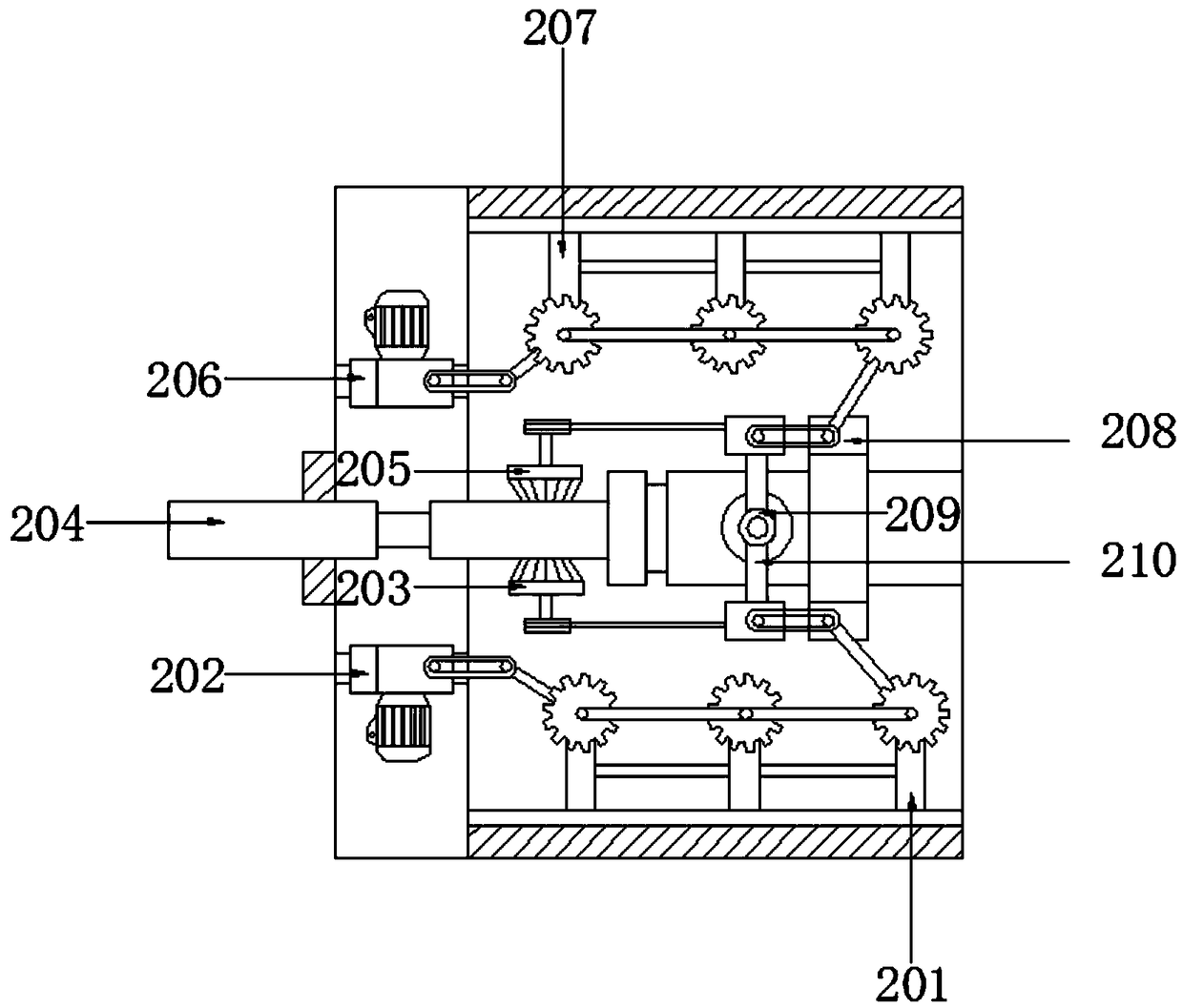

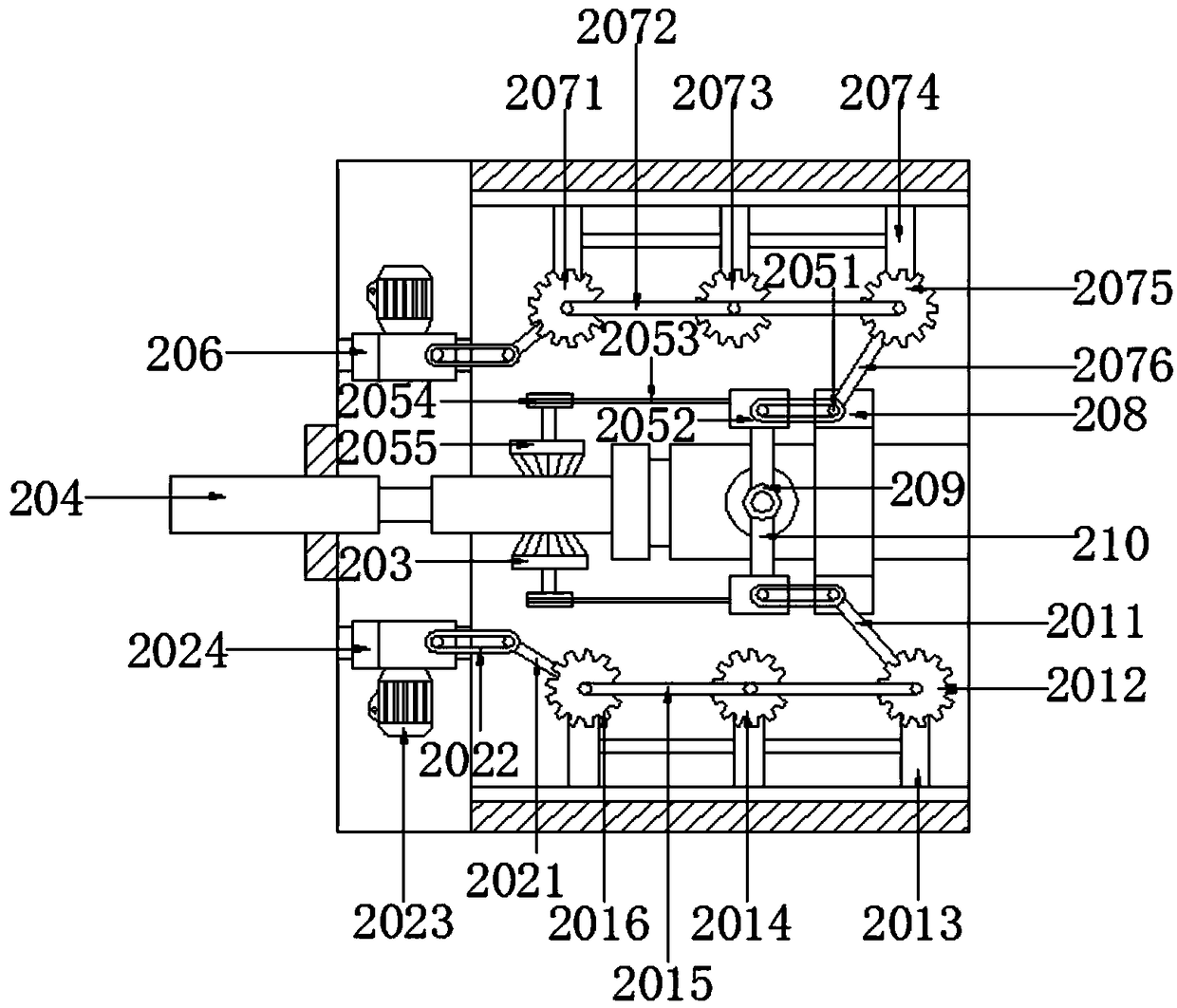

[0021]The buffer device 2 is composed of a lower gear backstop mechanism 201, a first generating set 202, a lower driving mechanism 203, a bearing body 204, an upper driving mechanism 205, a second generating set 206, an upper gear backstop mechanism 207, an elastic layer 208, and a rotating ten thousand Composed of a wheel 209 and a coupling rod 210, the lower gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com