Winding device for enameled wire production and processing technique thereof

A winding device and enameled wire technology, which are applied in the directions of transportation and packaging, transportation of filamentous materials, and thin material handling, etc., can solve the problems of enameled wire vibration, unsatisfactory winding effect, and inability to use reels, so as to avoid vibration, Easy to promote and use, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

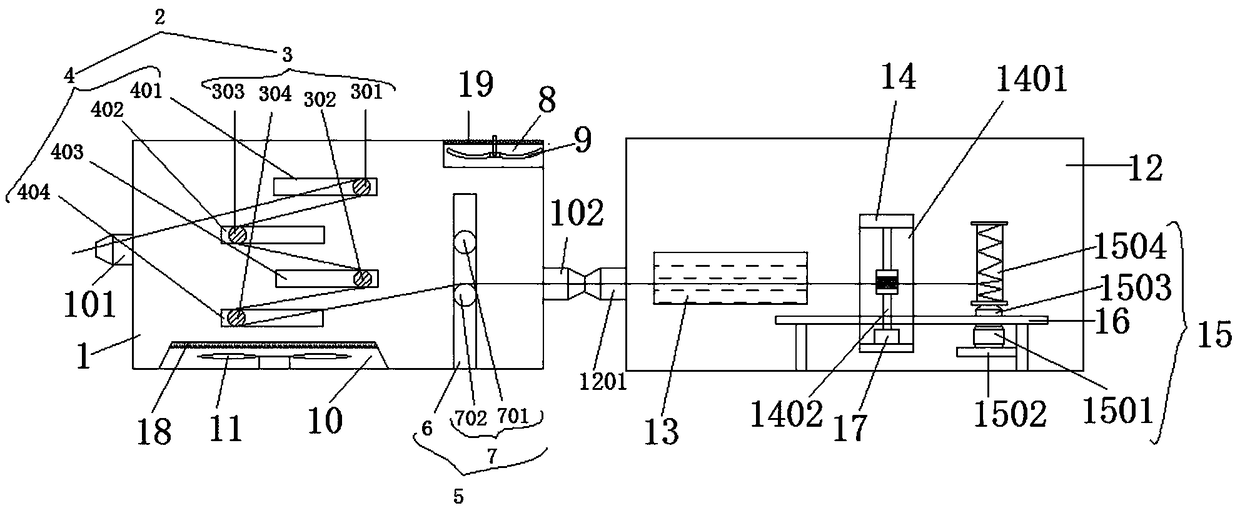

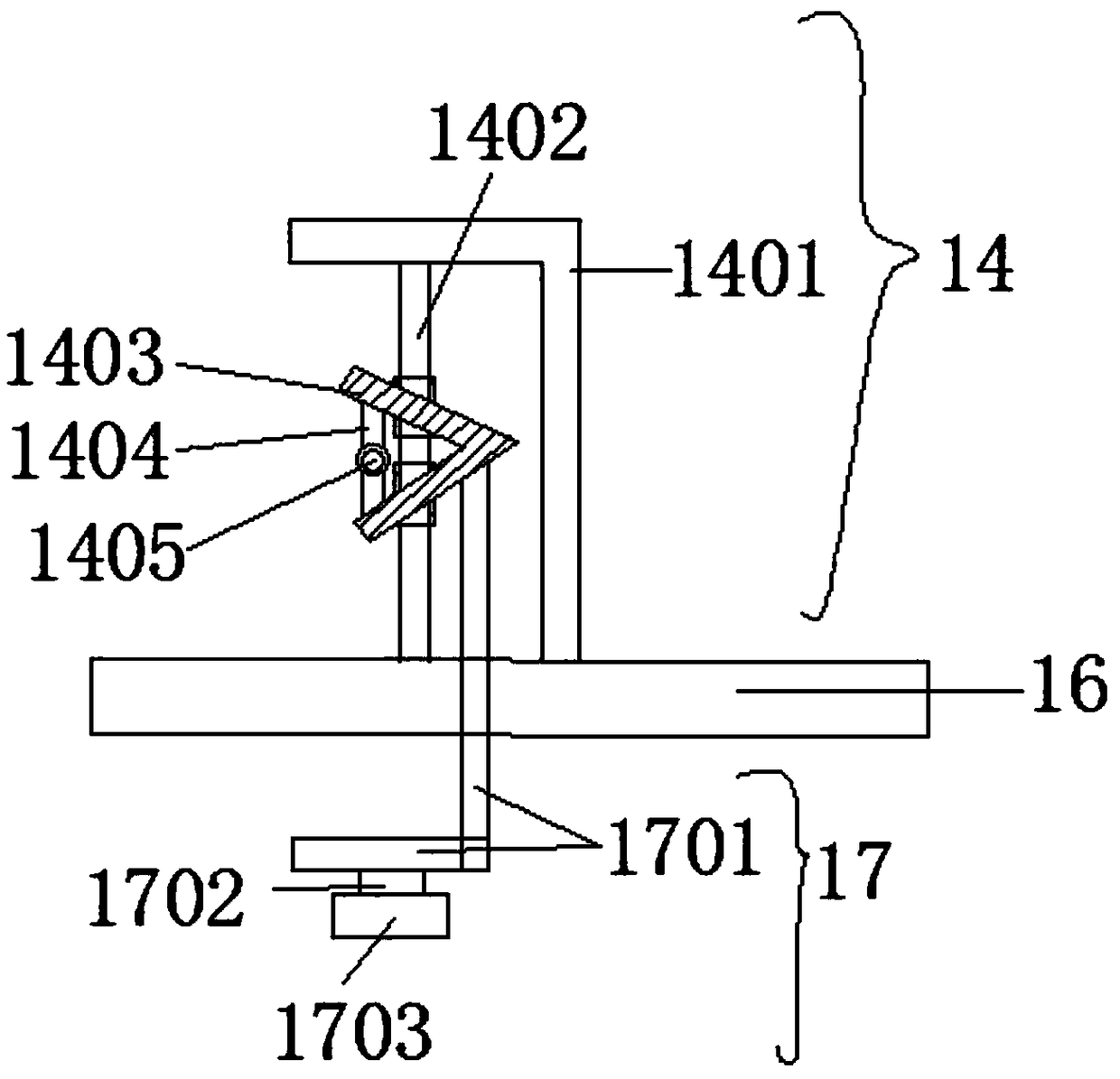

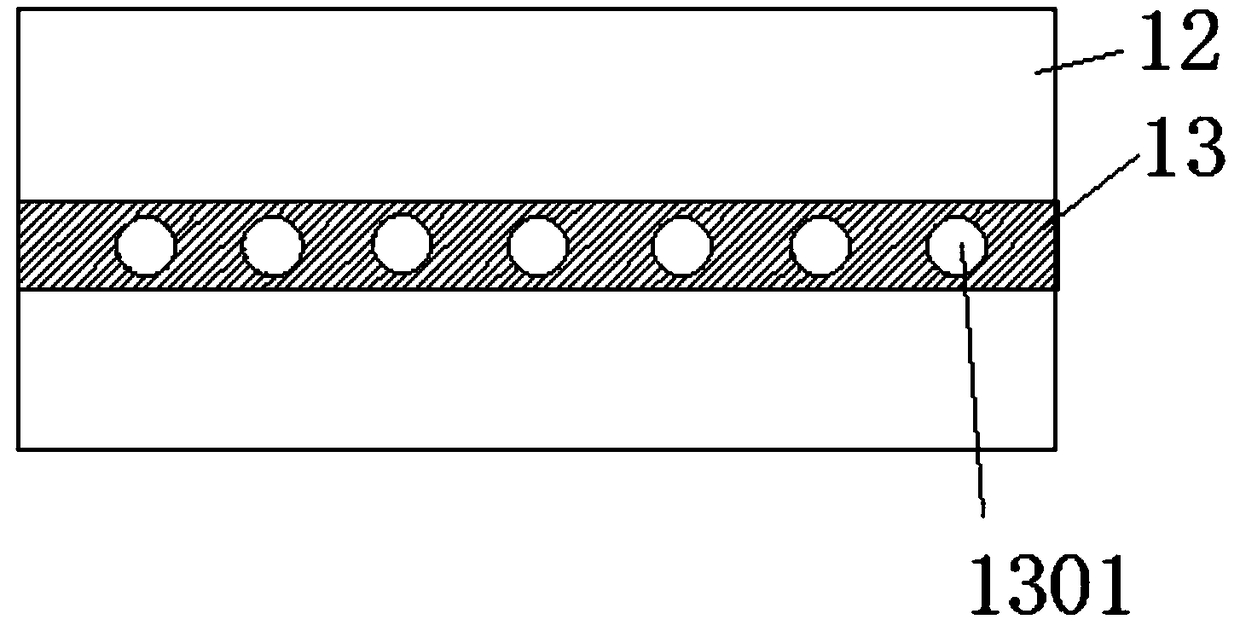

[0021] Embodiment 1: see figure 1 , figure 2 and image 3 Now, a kind of winding device based on enameled wire production provided by the present invention will be described, including a lead box 1, the front end of the lead box 1 is provided with a wire inlet 101, and the rear end of the lead box 1 is provided with an outlet port 102, the lead wire assembly 2 is provided inside the lead box body 1, and the lead wire assembly 2 includes a lead roll set 3, and the lead roll set 3 includes a lead roll, specifically a first lead roll 301, a second lead roll 302 , the third lead roller 303 and the fourth lead roller 304, the lead roller group 3 is installed inside the lead box body 1 through the strap group 4, and the strap group 4 is formed from top to bottom in the lead box body 1 The first board 401, the second board 402, the third board 403 and the fourth board 404 are formed, the right side of the board group 4 is provided with a transmission assembly 5, and the transmissi...

Embodiment 2

[0022] Example 2: see figure 1 , figure 2 and image 3 , as an improvement of the present invention, the upper end of the air outlet cavity 10 is provided with a filter 18 , and the upper end of the air inlet cavity 8 is provided with a filter layer 19 .

Embodiment 3

[0023] Embodiment 3: see figure 1 , figure 2 and image 3 , As an improvement of the present invention, the filter 18 adopts a HEPA filter, and the filter layer 19 adopts a bamboo charcoal filter layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com