Processing method of needle plate insertion sheet

A processing method and inserting technology, which are applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of easy occurrence of defective products, extremely high requirements for processing personnel, and high difficulty in operation, so as to reduce the processing difficulty and improve the processing accuracy. and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

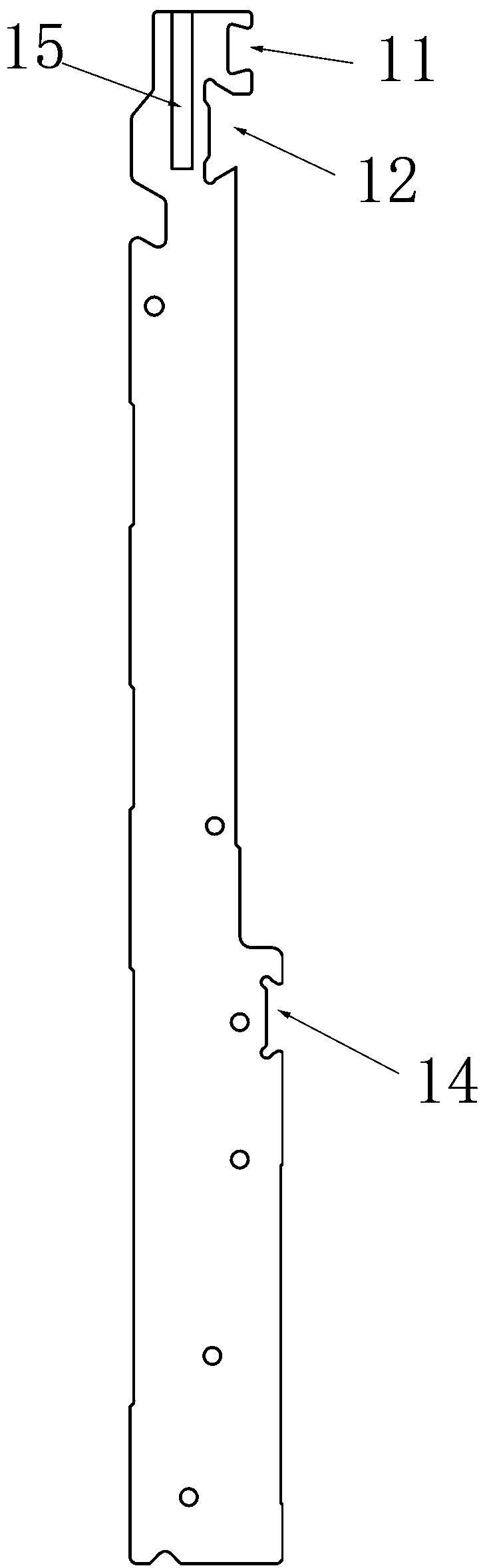

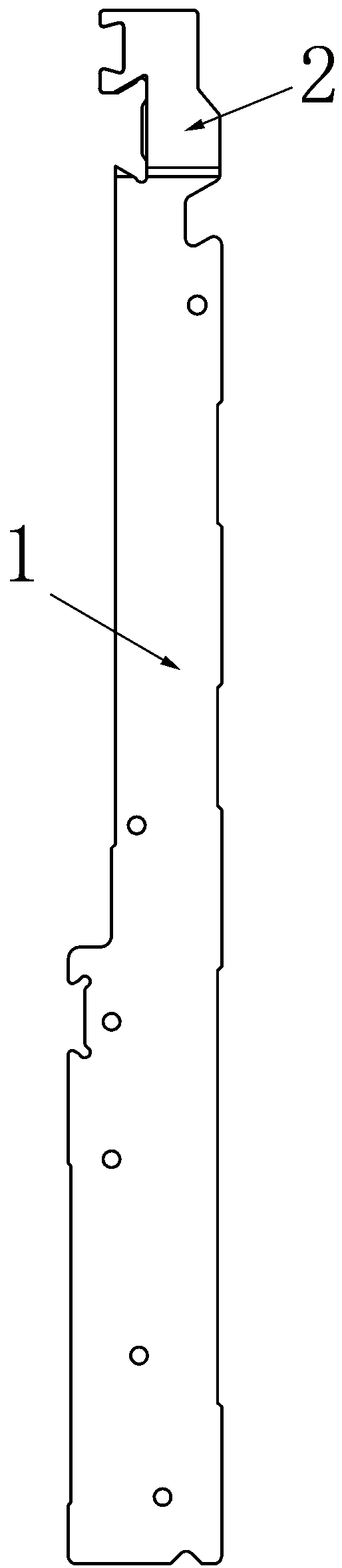

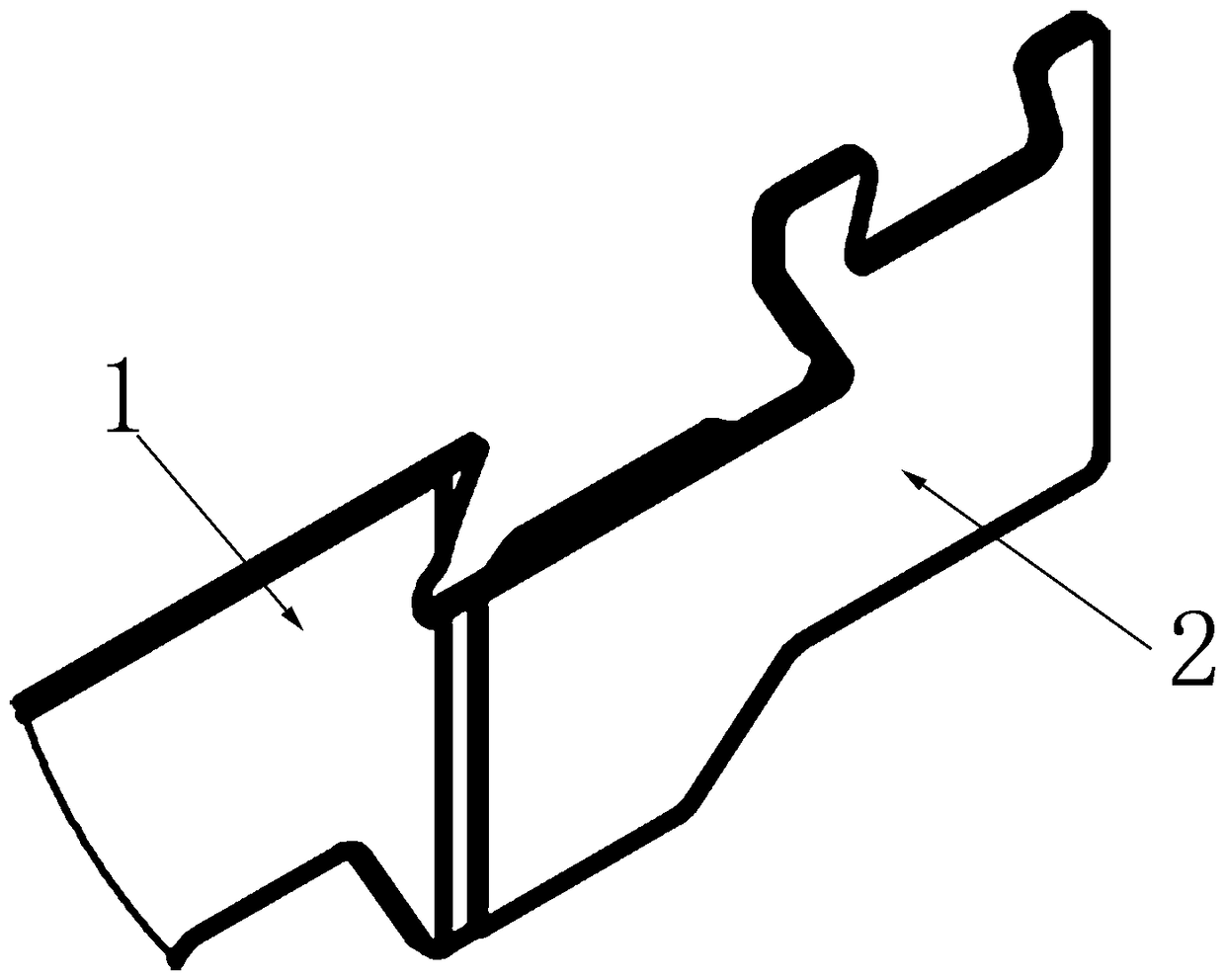

[0013] See attached picture. The insert described in this embodiment includes an insert body 1 and a patch 2. First, the sheet is processed into an insert body 1 and a patch 2 according to the model. The insert body 1 is a long strip structure and can be divided into a head and a patch. Tail, the side of the head is provided with two first notches 11 and the second notch 12 of inverted trumpet shape arranged side by side, and a slender U-shaped opening 13 with an upward opening is vertically arranged on the head, and is located on the head surface. middle position; the upper surface of the tail near the middle part of the body has a third notch 14; the patch 2 fits with the head of the insert body 1, and the outer contour of the patch is basically consistent with the head of the insert body. Welding and fixing as one body can be fixed by spot welding first, and then the edge is closed by laser welding; after fixing, the complete patch 2 cooperates with the insert body 1 with U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com