Heat-dissipation shock absorber

A shock absorber, thermal energy technology, used in springs/shock absorbers, springs made of plastic materials, mechanical equipment, etc., can solve problems such as equipment damage, rupture and damage to the rubber body of the rubber shock absorber, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

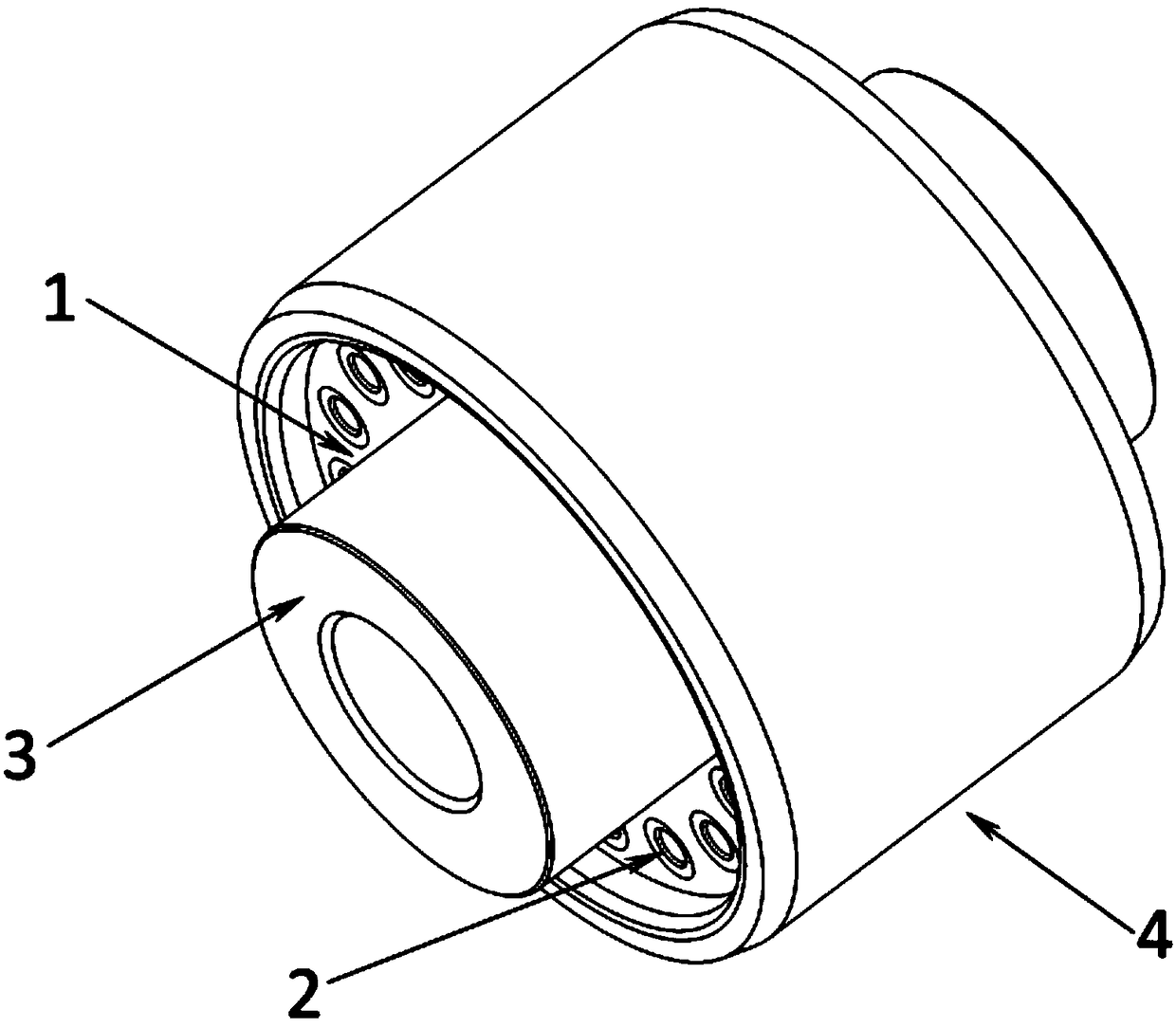

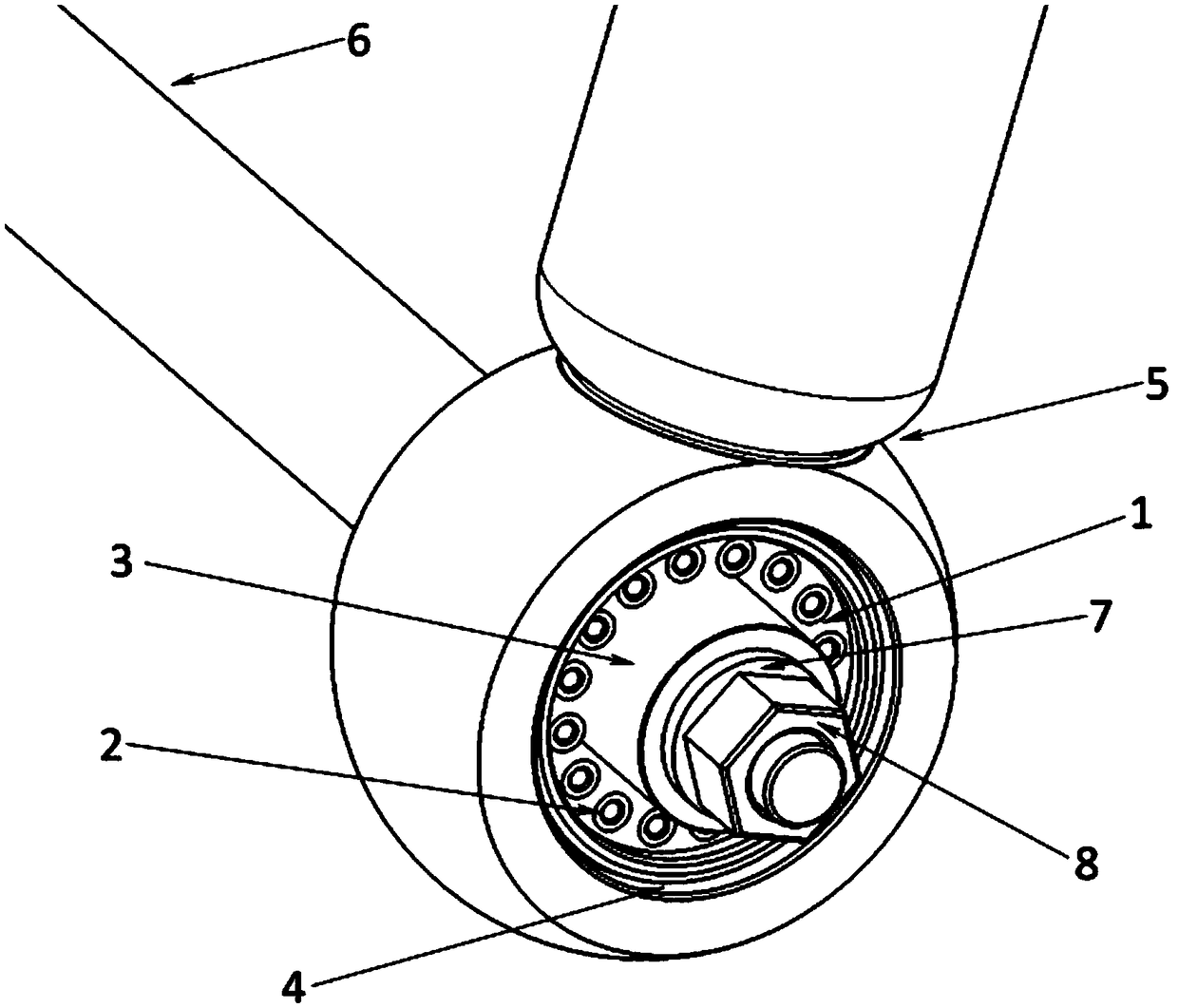

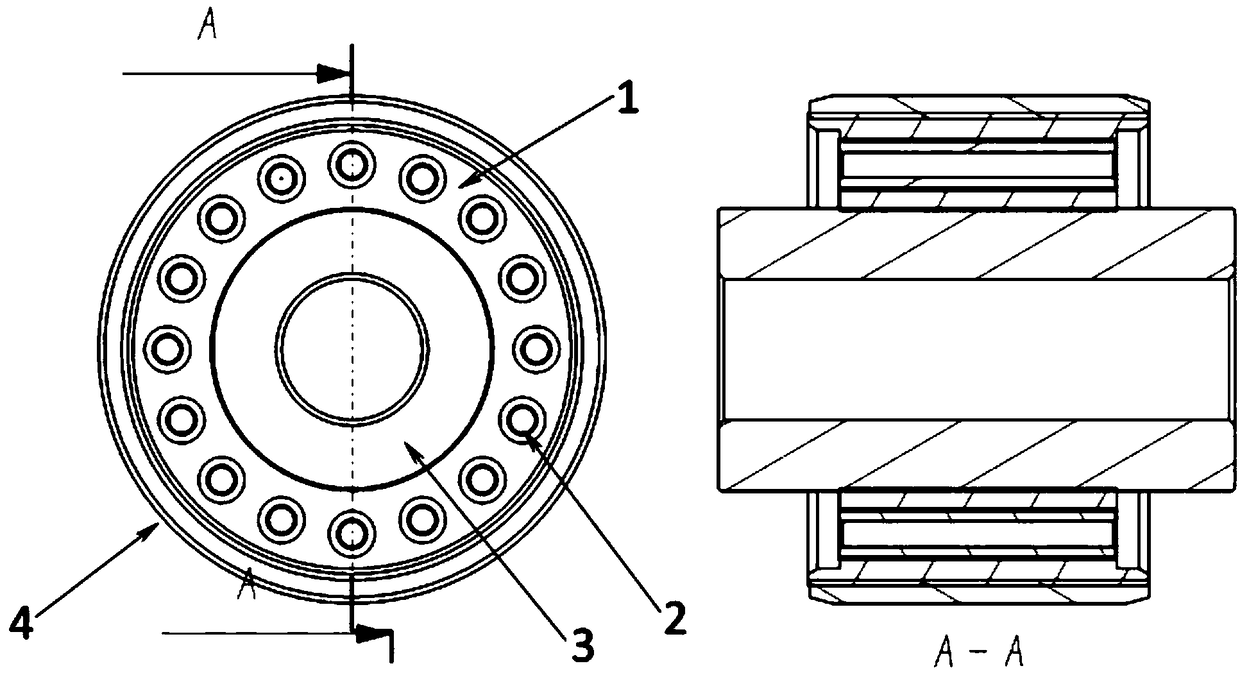

[0005] The specific embodiment of the patent of the present invention is: when the object vibrates, the bearing 6, the gasket 7, the bolt 8 and the inner casing 3 of the heat dissipation shock absorber are fixed, and the vibration kinetic energy is transmitted to the rubber shock absorber. The shock body 1 converts heat energy and accumulates it, and dissipates the heat energy through the metal tube radiator 2 in the rubber shock absorber 1, thereby reducing and avoiding the vibration source passing through the shock absorber outer sleeve 4 and the shock absorber load. The shock absorber bracket 5 is transmitted to the load, so as to achieve the purpose of excellent shock absorption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com