Combustor head

A stove head and mixing chamber technology, which is applied to the field of kitchen gas stoves, can solve the problems of insufficient flame combustion, insufficient supply of combustion-supporting air, and flameout when sitting on a pot, so as to improve the combustion efficiency, reduce the difficulty of cleaning, and achieve the effects of sufficient gas combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

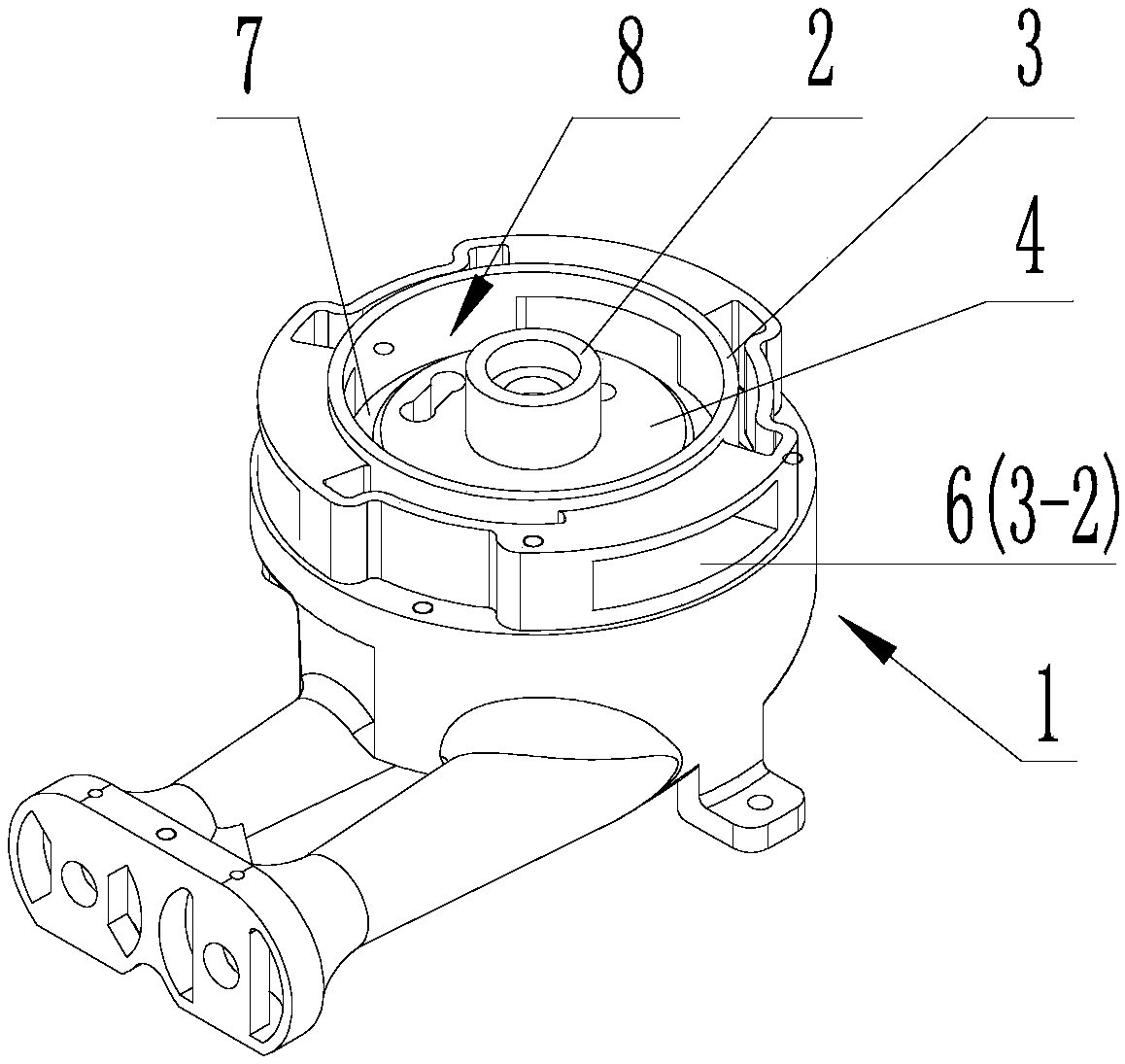

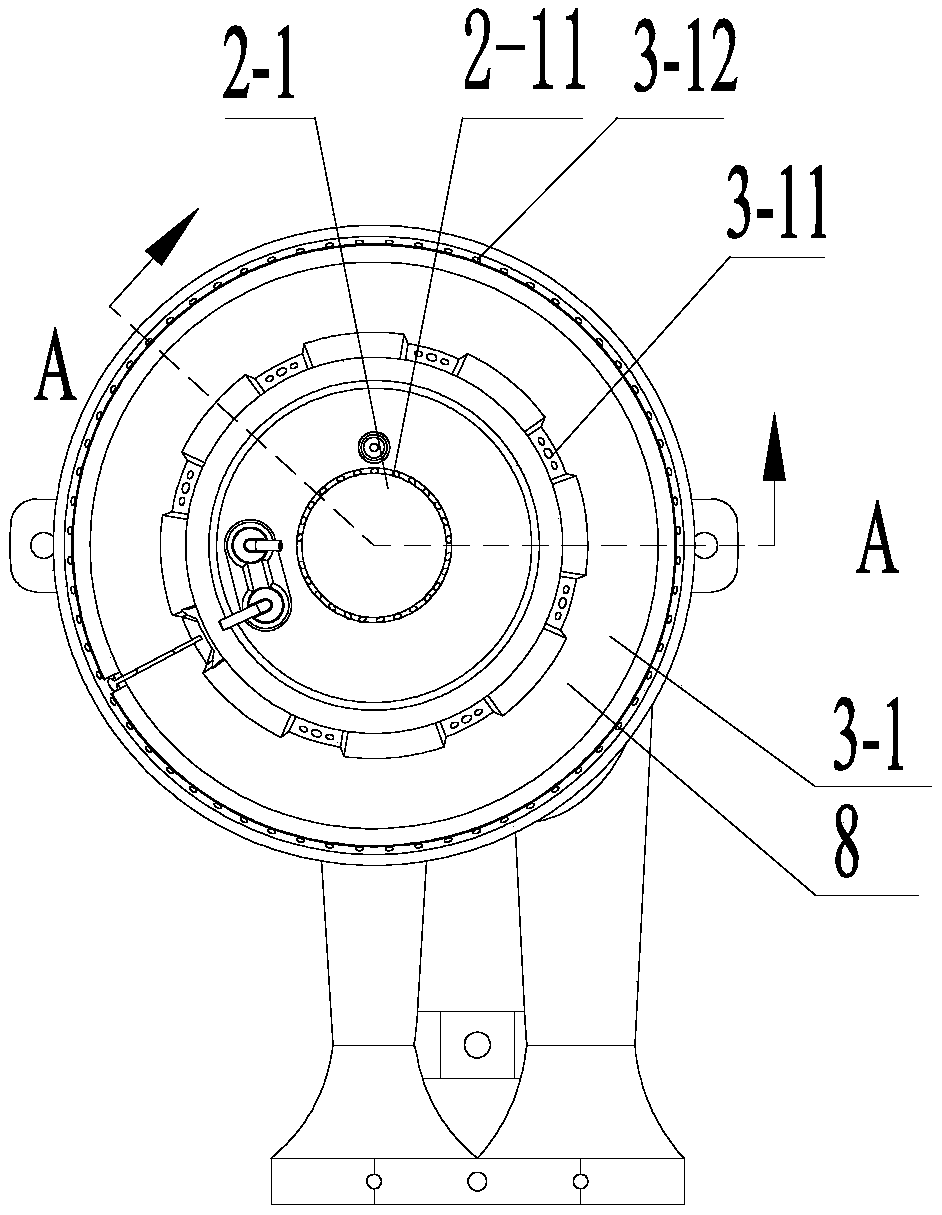

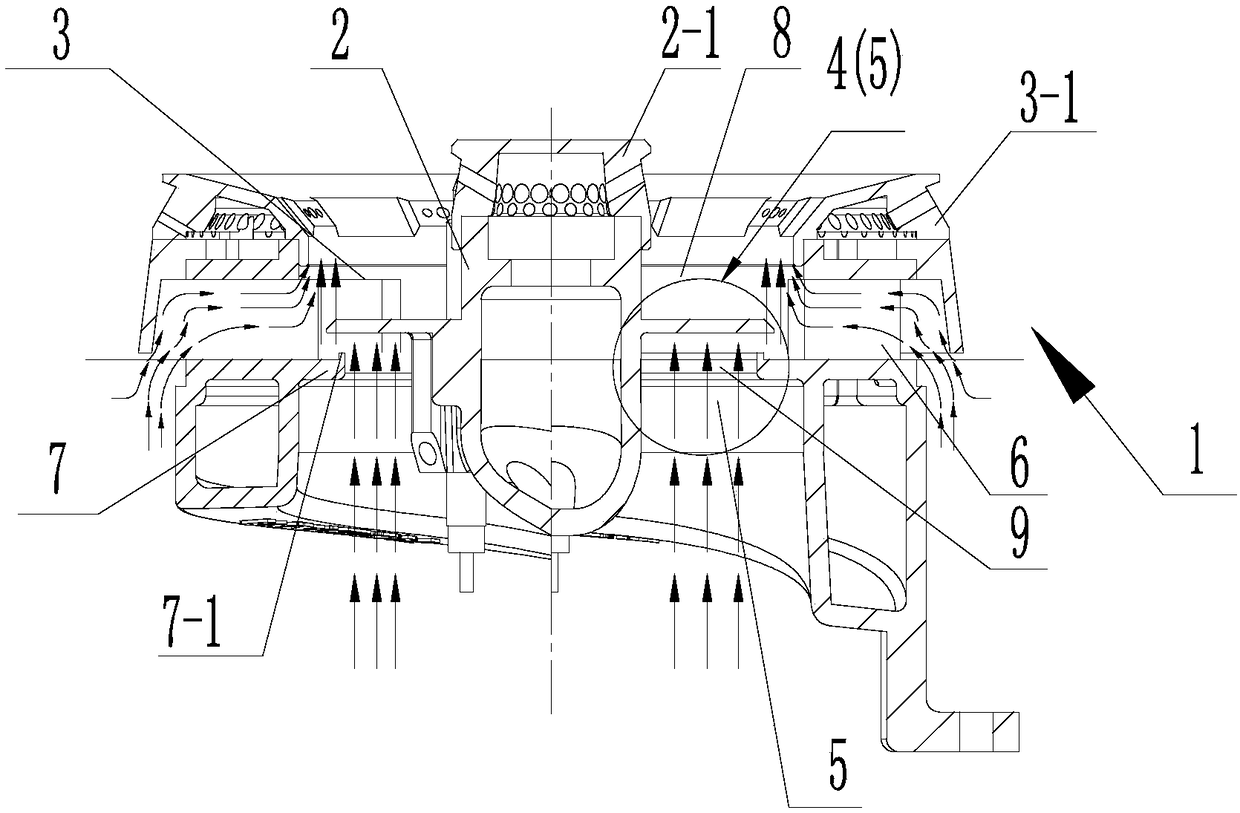

[0030] Such as figure 1 , 3 In the example of the present invention, a furnace head 1 of the present invention includes an inner ring mixing chamber 2, an outer ring mixing chamber 3 and a secondary air supplementary channel 5, and is arranged in the inner ring mixing chamber 2 and the outer ring mixing chamber 3 is suitable for the passage area 8 connected with the secondary air supplementary passage 5, and the upper bottom wall 4 and the lower bottom wall 7 are arranged at intervals below the passage area 8, and the upper bottom wall 4 and the lower bottom wall 7 are in the The projections in the vertical direction partially overlap, and an annular long hole 9 as a secondary air supplementary hole is provided in the space between the upper bottom wall 4 and the lower bottom wall 7. One end of the annular long hole 9 communicates with the passage area 8, and the other end It communicates with the atmosphere below the burner 1.

[0031] In this embodiment, the open cavity at...

Embodiment 2

[0034] Such as figure 1 , 3 In the example of the present invention, the furnace head 1 of the present invention includes an inner ring mixing chamber 2 and an outer ring mixing chamber 3, and a passage area 8 is arranged between the inner ring mixing chamber 2 and the outer ring mixing chamber 3, and the passage area 8 The upper bottom wall 4 and the lower bottom wall 7 arranged at intervals up and down are arranged below the upper bottom wall, and the interval area between the upper bottom wall 4 and the lower bottom wall 7 is provided with an annular elongated hole 9 communicating with the passage area 8 and the external atmosphere, and the annular elongated hole 9 is hidden. It is arranged directly below the upper bottom wall 4 , surrounds the inner ring mixing chamber 2 , and is arranged close to the radially outer wall of the inner ring mixing chamber 2 , and is used to supplement the secondary air required for combustion into the passage area 8 . The inner ring mixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com