A fast double-sided laser printer

A laser printer, printer technology, applied in optics, electrographics, instruments, etc., can solve the problems of affecting printing speed, poor practicability, and complicated operation, and achieve the effect of improving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

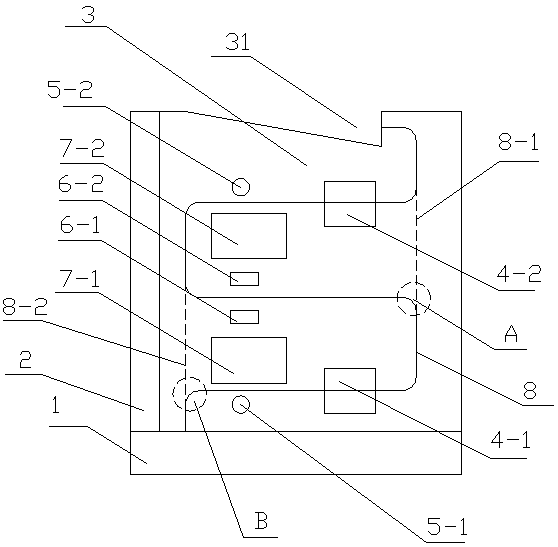

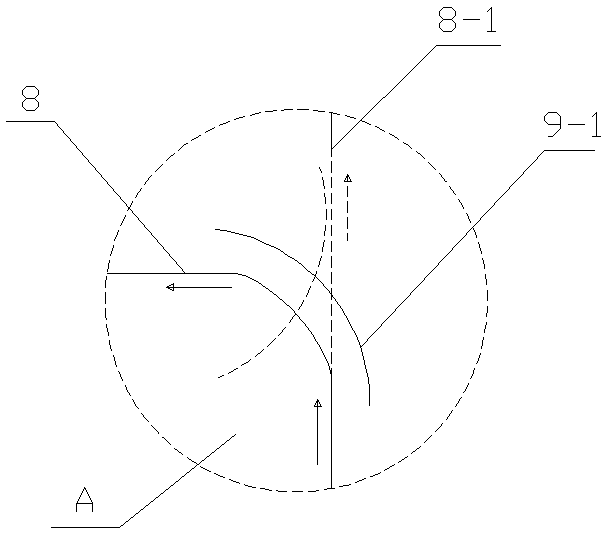

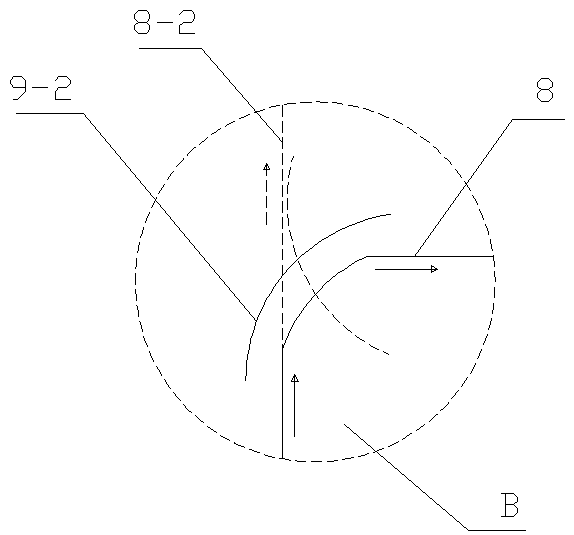

[0010] Below in conjunction with accompanying drawing, the present invention is described in detail: with reference to accompanying drawing figure 1 , figure 2 and image 3 , a fast double-sided laser printer of the present invention, comprising a control system, a paper tray 1, a door cover 2, a printer body 3, a lower fixing assembly 4-1, an upper fixing assembly 4-2, a lower transfer roller 5-1, an upper Transfer roller 5-2, lower laser 6-1, upper laser 6-2, lower toner cartridge 7-1, upper toner cartridge 7-2, front paper feed switch 9-2 and rear paper feed switch 9-1. The control system can judge whether double-sided printing is required according to the data received by the printer, control whether the upper toner cartridge 7-2 and the lower toner cartridge 7-1 need to operate for imaging, whether the upper fixing assembly 4-2 and the lower fixing assembly 4-1 need to Work and control the direction of the front paper feed switch 9-2 and the rear paper feed switch 9-1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com