Bi-directional ESD protection device of latch-up immunity

A device and latch-up technology, applied in the field of ESD protection devices, can solve the problems of reducing robustness and increasing area, and achieve the effect of improving robustness and avoiding latch-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

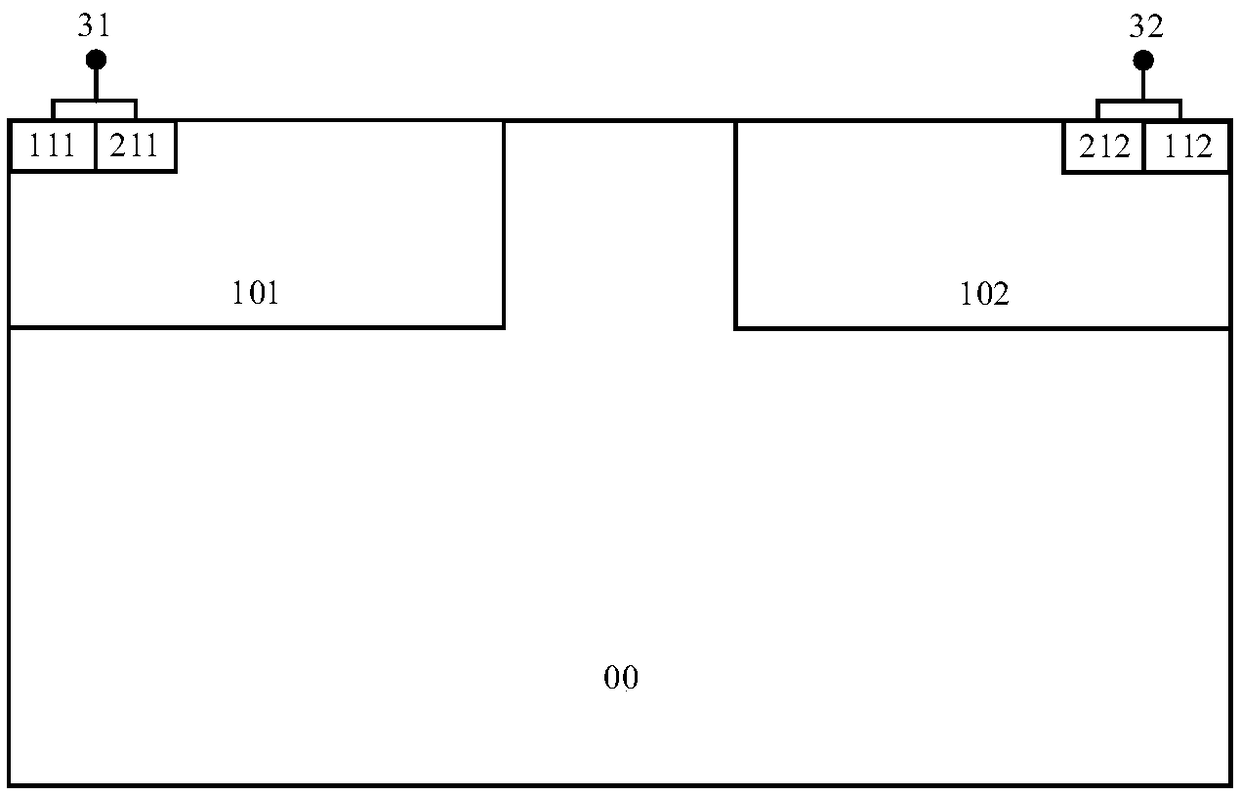

[0028] like image 3 As shown, the device structure of this embodiment includes: a P-type substrate 00, an N-type region 01 located above the P-type substrate; a first P+ contact region 211 located on the upper left side inside the N-type region 01, and The first N+ contact region 111 on the upper left side of the interior of 01, the first P+ isolation region 221 located on the upper left side of the N-type region 01, and the first P-type buried layer 231 located inside the N-type region 01; wherein, the first P+ The contact region 211 is located on the left side of the first N+ contact region 111, the first P+ isolation region 221 is located on the right side of the first N+ contact region 111, the first P-type buried layer 231 is located on the first N+ contact region 111, the first P+ contact region 211 , below the first P+ isolation region 221 and tangent to the first N+ contact region 111, the first P+ contact region 211, and the first P+ isolation region 221; the TOP lay...

Embodiment 2

[0037] like Figure 4 As shown, the difference between the device structure of this embodiment and that of Embodiment 1 is that the TOP layer 24 is a plurality of discontinuous spacer sub-regions.

Embodiment 3

[0039] like Figure 5 As shown, the difference between the device structure of this embodiment and Embodiment 1 is that: the first N+ contact region 111, the first P+ contact region 211 and the first P+ isolation region 221 form a metal anode 31 through a metal short circuit; the second N+ contact The region 112 , the second P+ contact region 212 and the second P+ isolation region 222 form a metal anode 32 by a metal short.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com