Motor control system

A motor control and controller technology, applied in control systems, AC motor control, electric vehicles, etc., can solve the problems of efficiency reduction, expansion of operating range, limited speed effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The preferred embodiments of the present invention are described below with reference to the drawings. The foregoing and other technical content, features and effects of the present invention are described in the following detailed description of a preferred embodiment with reference to the drawings. The directional terms mentioned in the following embodiments, such as: up, down, left, right, front or back, etc., are only directions with reference to the attached drawings. Accordingly, the directional terms are used to illustrate and not to limit the invention.

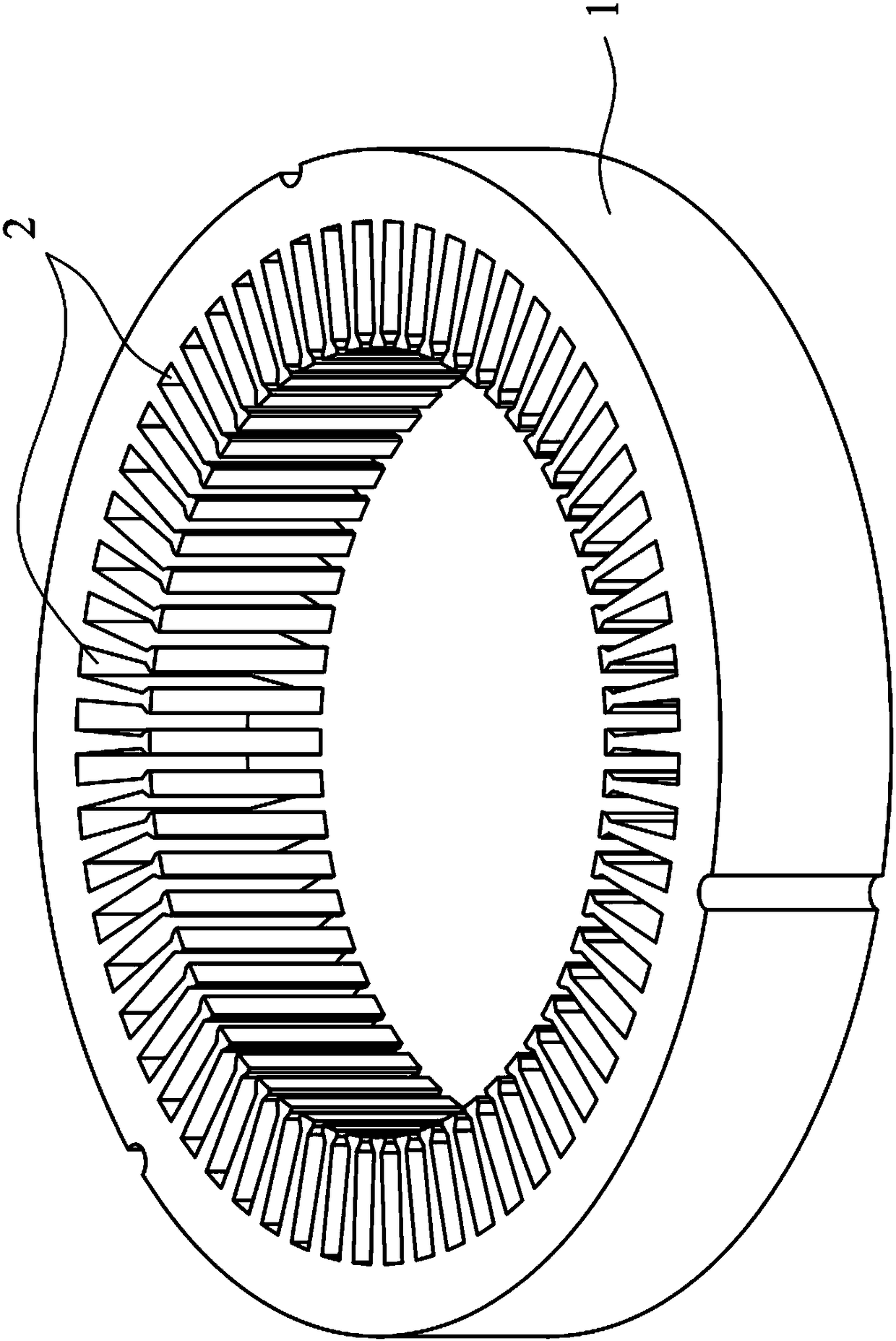

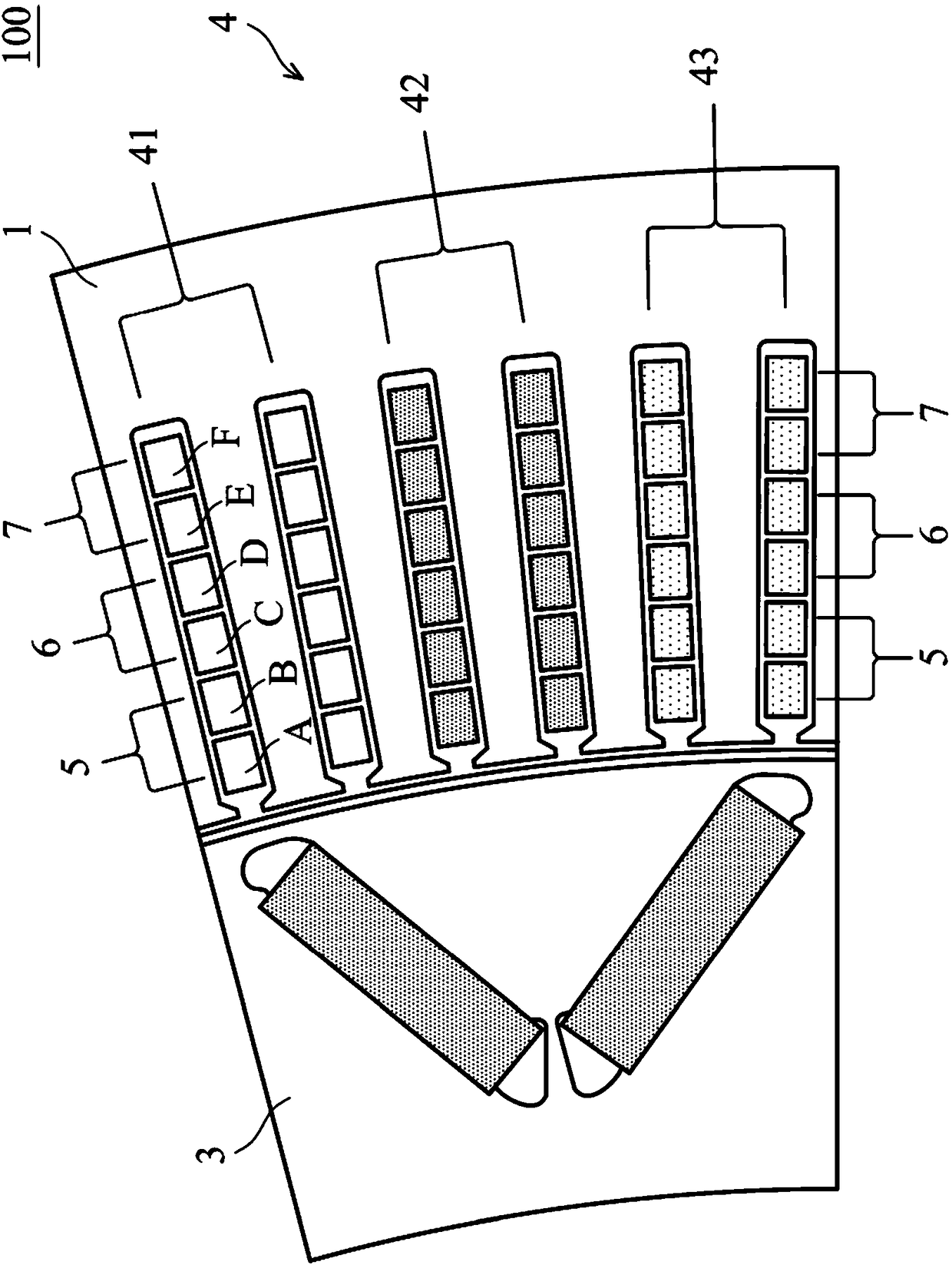

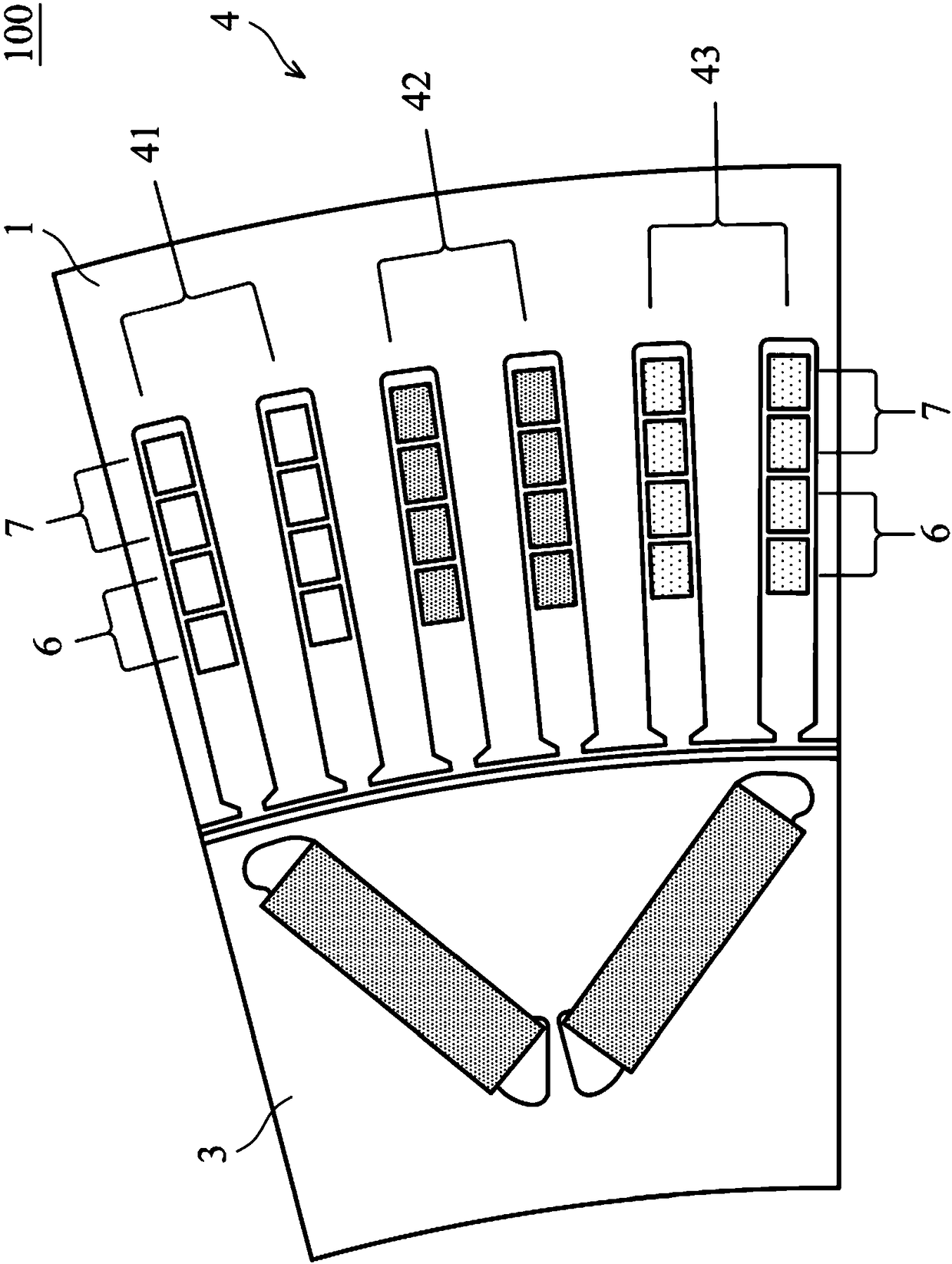

[0054] refer to Figure 7-9 , the motor control system of an embodiment of the present invention can control the conductance of the motor winding, including an electric motor 100 and a frequency converter 9, and the electric motor 100 includes a stator 1 and a rotor 3 (shown in figure 2 , 3 ). figure 1 The stator of the electric motor 100 is shown, the stator 1 is a hollow annular iron core, and a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com