Compression device and installation structure of small arm casting and reducer synchronous wheel assembly

A technology of pressing device and installation part, which is applied in metal processing, manipulators, metal processing equipment, etc. It can solve the problems that the pressing device cannot work synchronously with the manipulator, and the installation of the synchronous wheel assembly of the reducer and the forearm casting is not in place, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

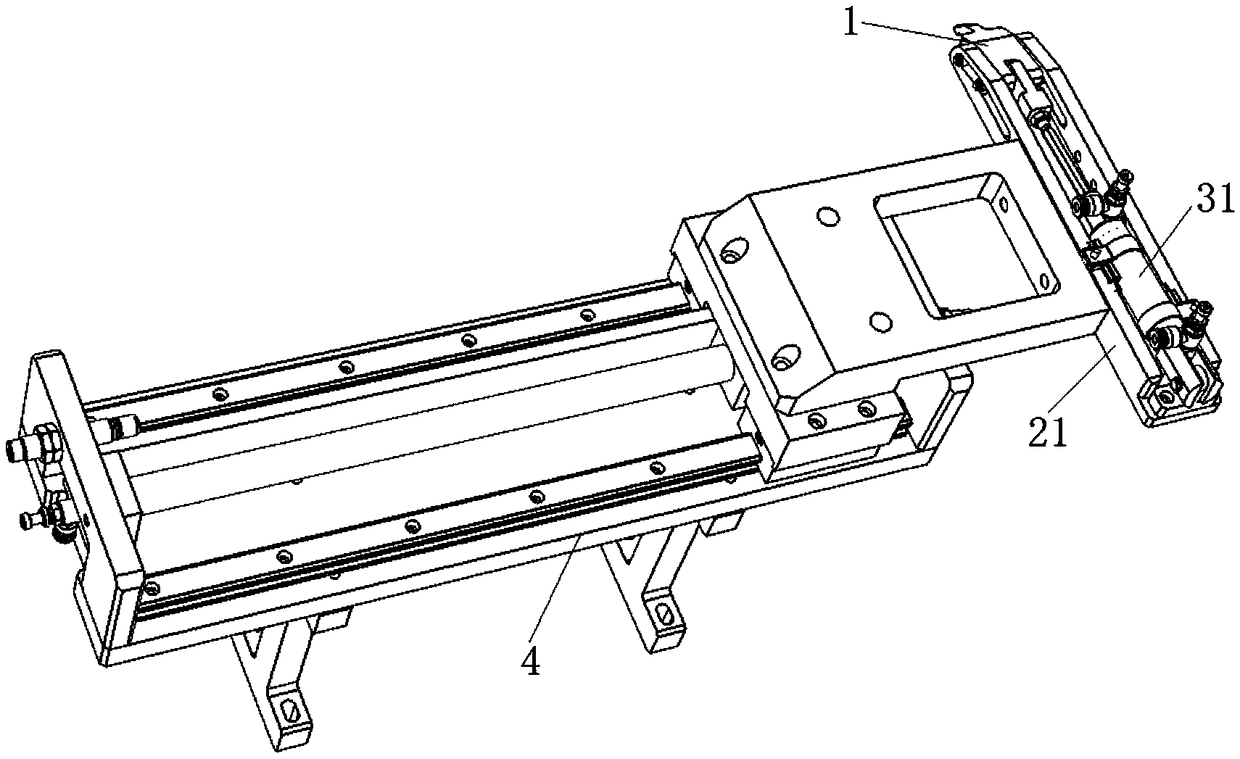

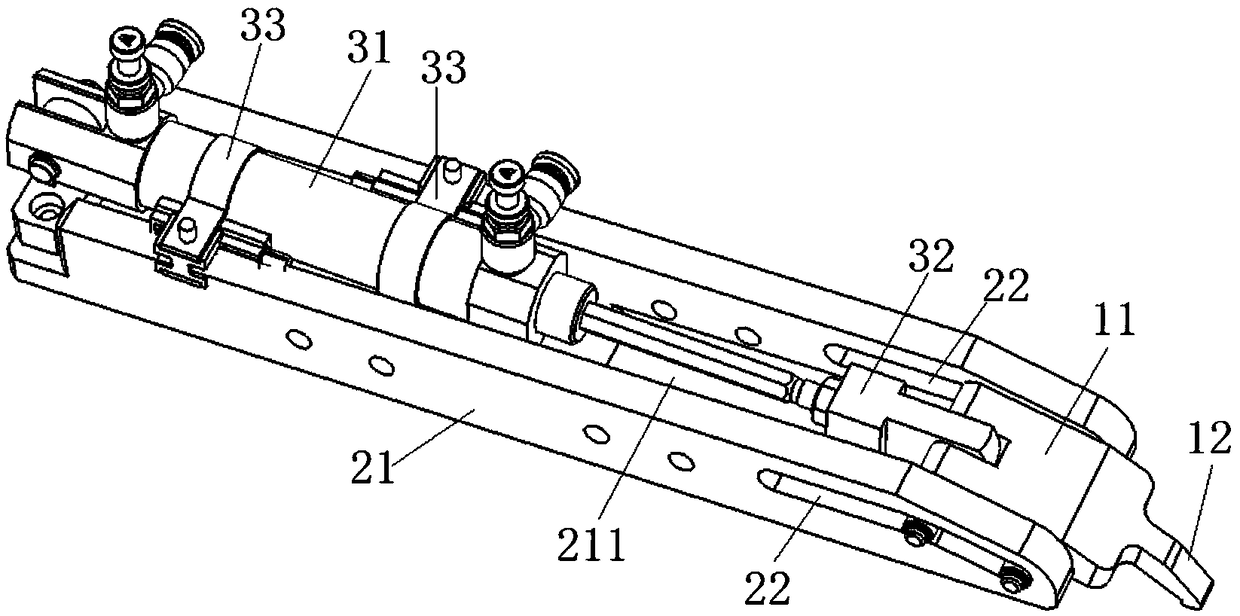

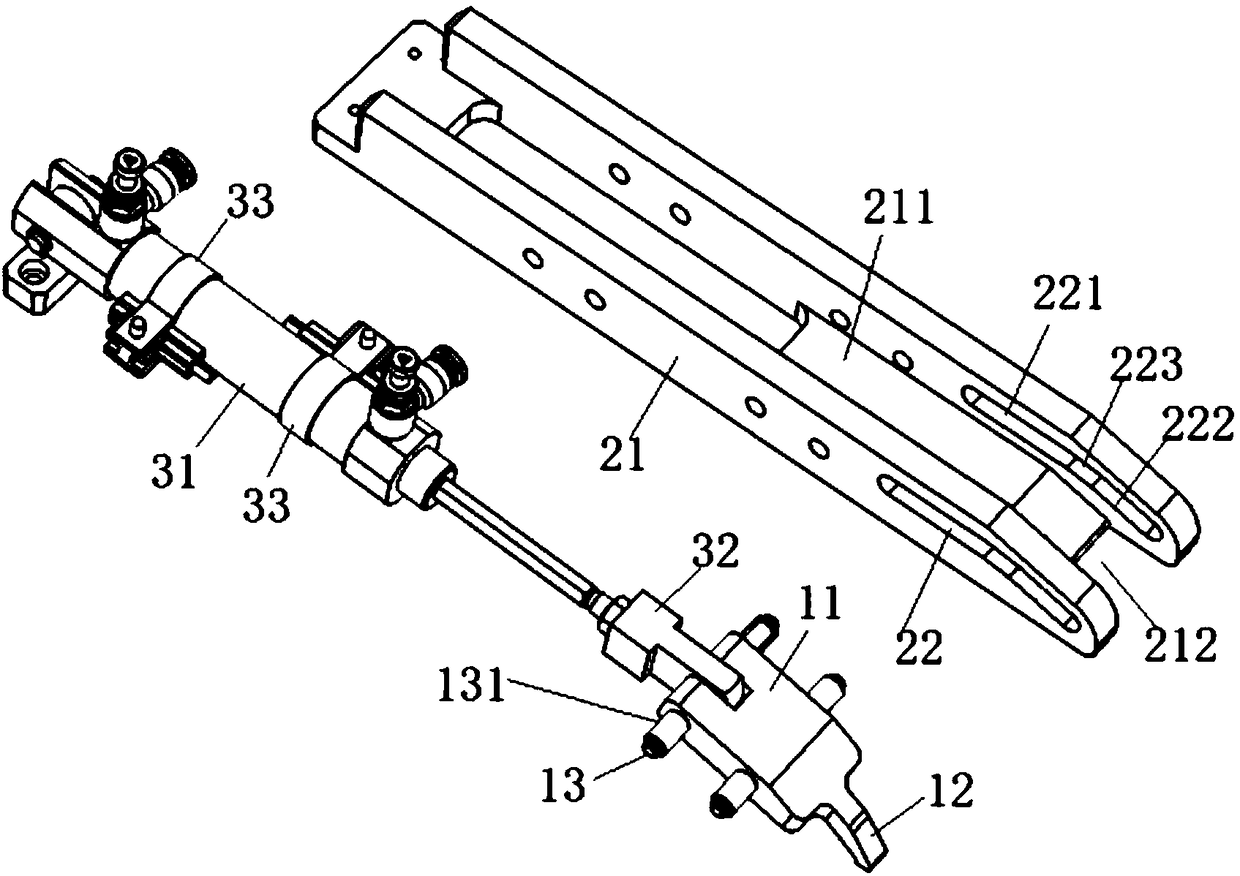

[0046] This embodiment provides a pressing device, such as Figure 1 to Figure 5As shown, it includes a motion conversion component, a pressure head 1 , a first driver 31 and a base 21 .

[0047] Such as figure 1 As shown, the motion conversion component includes a sliding slot 211 disposed on the base 21 with the notch facing upwards, and one and opposite guide holes 22 are respectively provided on the two side walls of the sliding slot 211 . Wherein, the indenter 1 is driven by the first driver 31 to be slidably arranged in the chute 211, and the two ends of the indenter 1 are respectively slidably arranged in a guide hole 22, but the bottom of the indenter 1 is in contact with the guide hole 22. The bottom of the chute separates.

[0048] Such as figure 2 As shown, the first driver 31 is installed in the chute and its telescopic shaft performs telescopic movement along the chute 211. For example, the first driver 31 is an air cylinder, and the ram 1 is connected to the ...

Embodiment 2

[0068] This embodiment provides an installation structure of the forearm casting and the synchronous wheel assembly of the reducer, including a workbench, two pressing devices in Embodiment 1, and a manipulator. Among them, the workbench is set horizontally, and the two pressing devices are relatively arranged above the workbench; the manipulator is used to pick and place the forearm casting and the synchronous wheel assembly of the reducer on the workbench.

[0069] With the installation structure of this embodiment, when it is necessary to install the reducer synchronous wheel assembly on the forearm casting, first place the forearm casting on the workbench, and use the manipulator to vertically embed the reducer synchronous wheel assembly into the forearm casting In the inner hole; at the same time, the pressure head 1 of the two pressing devices in Embodiment 1 extends into the inner hole of the forearm casting along the horizontal direction, and applies a downward pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com