Hardware plate grinding treatment technology

A processing technology and metal plate technology, which is applied in the field of grinding processing, can solve the problems of affecting the grinding effect and grinding accuracy, and the metal dust cannot be cleaned in time, so as to improve the grinding effect, speed up the moving frequency, and improve the efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

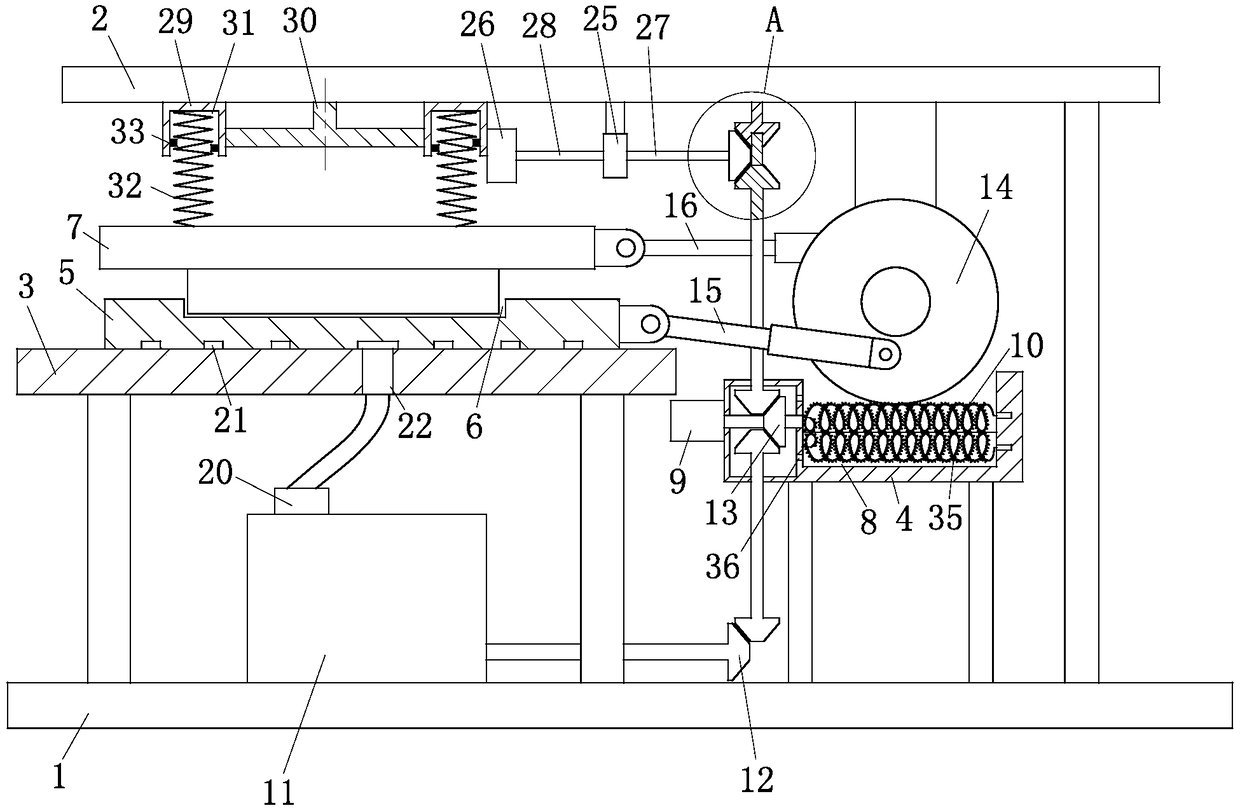

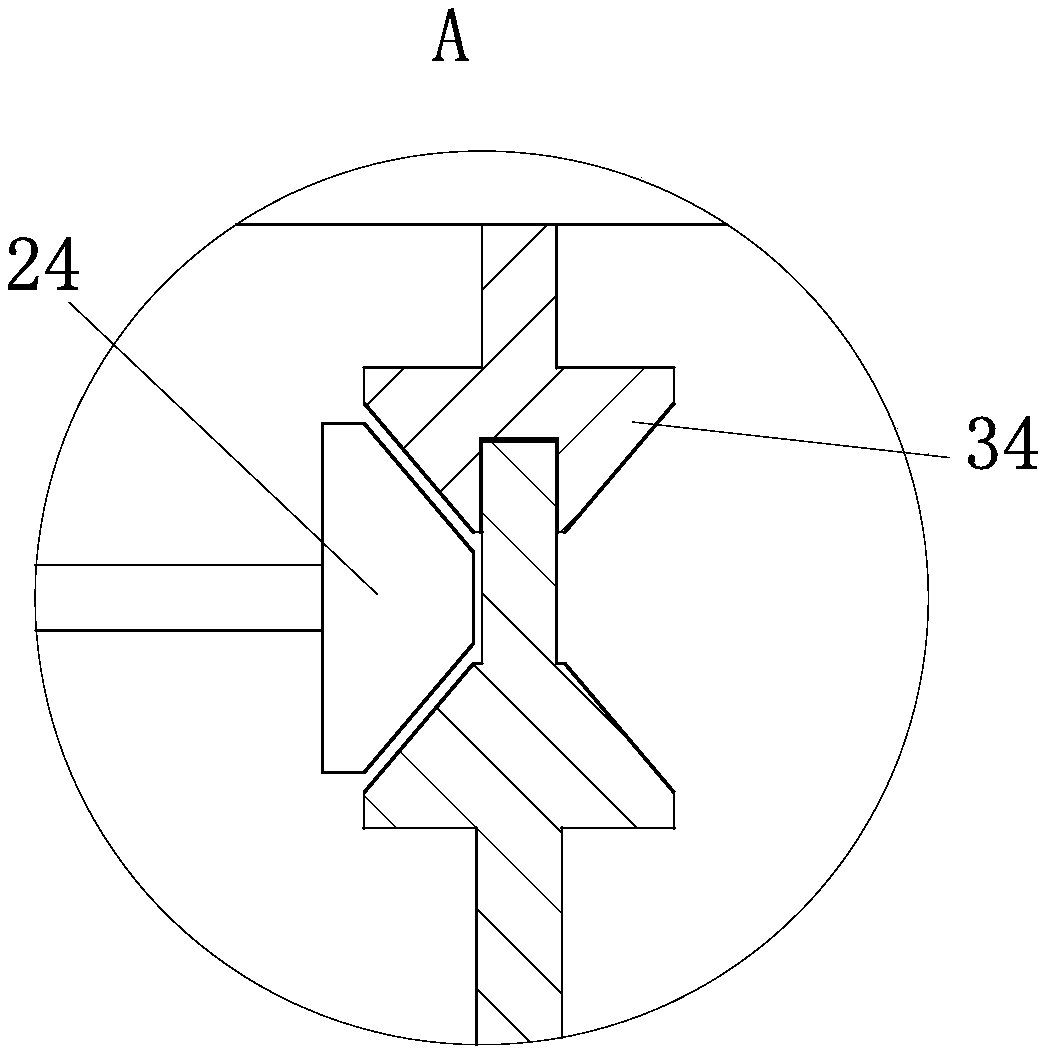

[0031] use Figure 1-Figure 6 A polishing treatment process for a metal plate according to an embodiment of the present invention is described as follows.

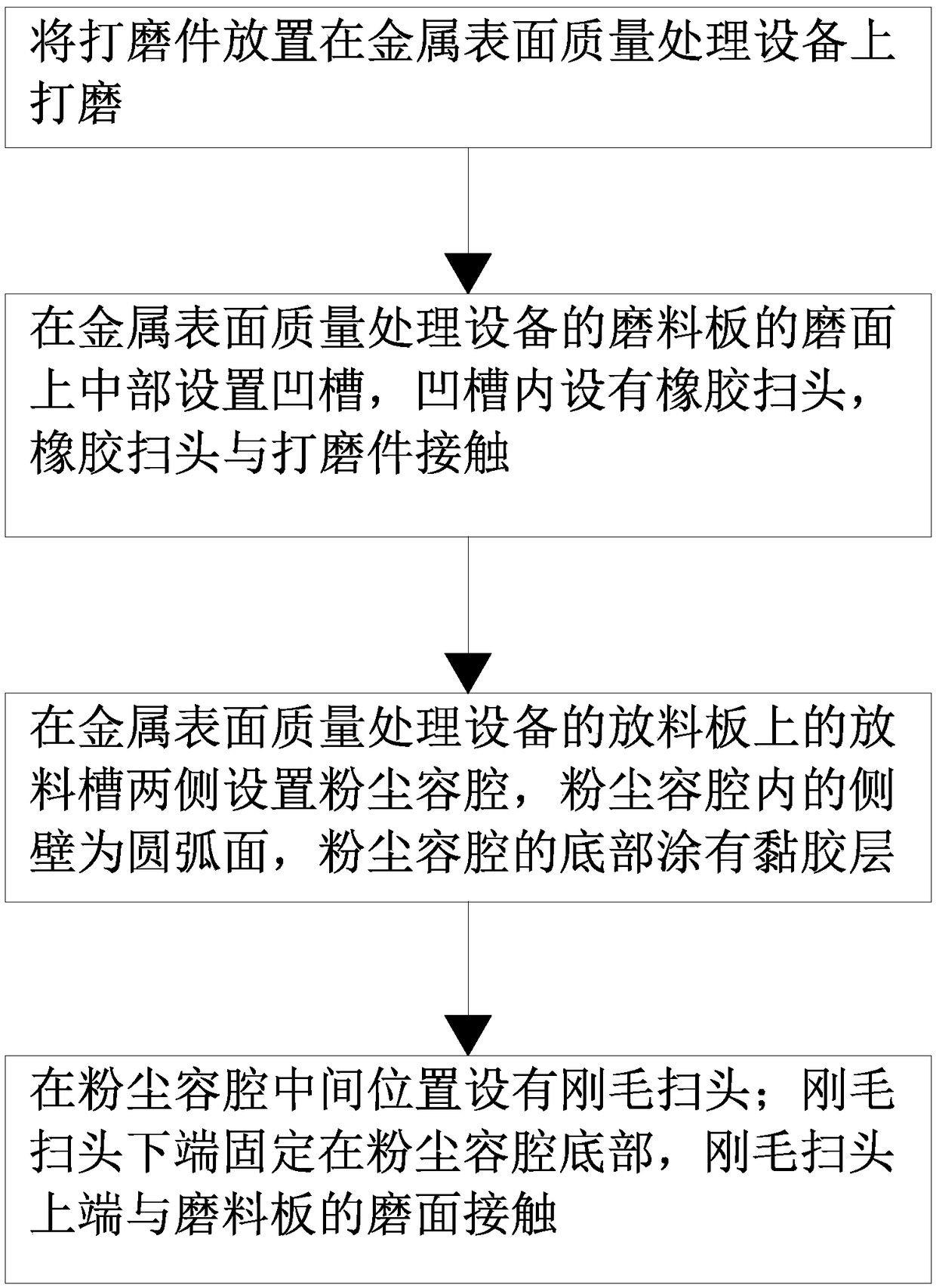

[0032] Such as Figure 1 to Figure 5 As shown, a kind of metal plate polishing treatment process of the present invention, this process comprises the following steps:

[0033] S1: Place the grinding piece on the metal surface quality treatment equipment for grinding; by using the metal surface quality treatment equipment, the relative frustration speed and frequency between the abrasive plate 7 and the discharge plate 5 are strengthened, and the grinding effect of the grinding piece is improved.

[0034] S2: A groove is set in the middle of the grinding surface of the abrasive plate 7 of the metal surface quality treatment equipment in S1, and a rubber sweeper is arranged in the groove, and the rubber sweeper contacts the grinding piece to sweep away the metal dust on the grinding piece; By setting the rubber sweep head,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com