Air duct, dust removal device and method

A technology of blower and sleeve, which is applied in the field of dust removal device and blower, which can solve the problems of hidden dangers in quality and safety, no protection on the surface of conductors, and easy adhesion of dust to traction belts, etc., so as to reduce the loss of human, financial and material resources and improve product quality , reducing the effect of replacement and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The present invention will be further described below in conjunction with the drawings and embodiments:

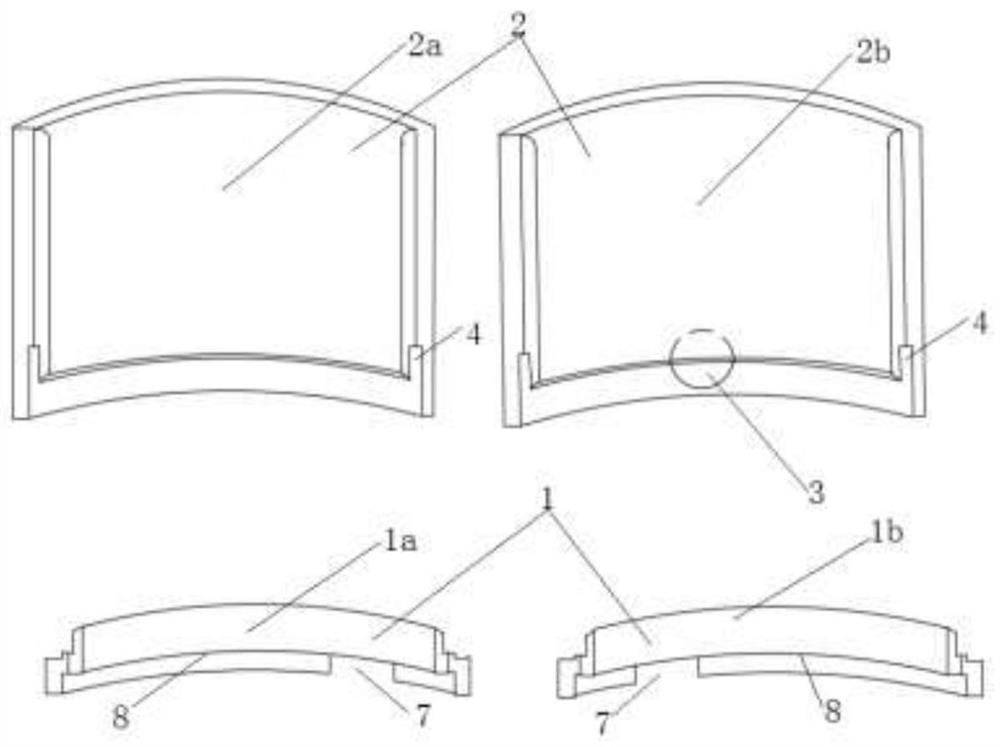

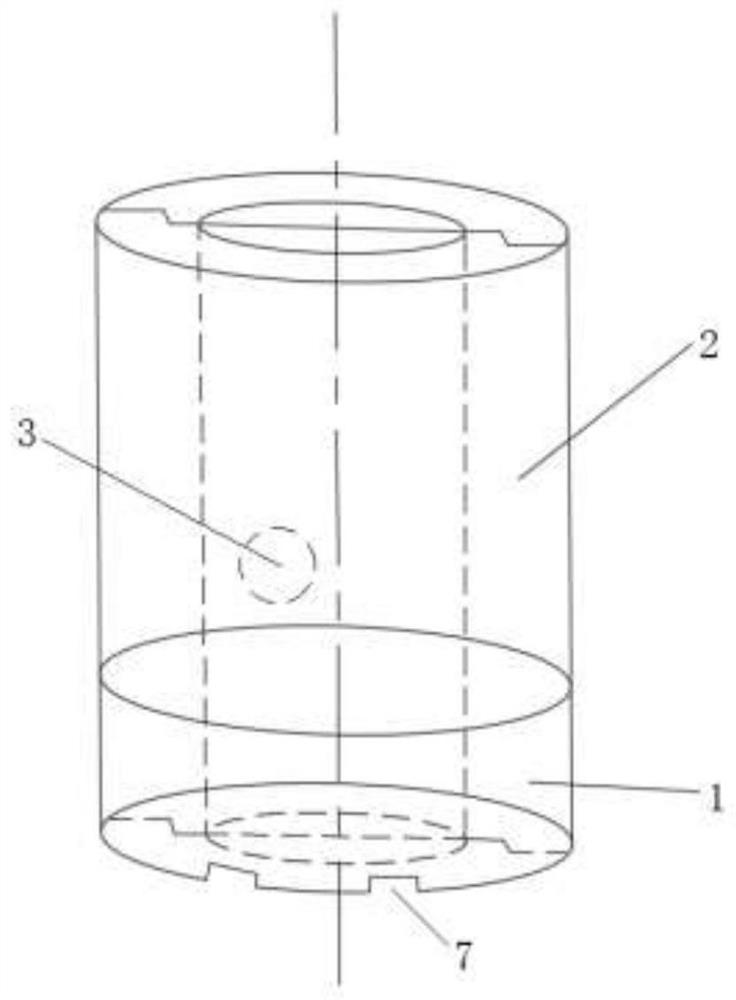

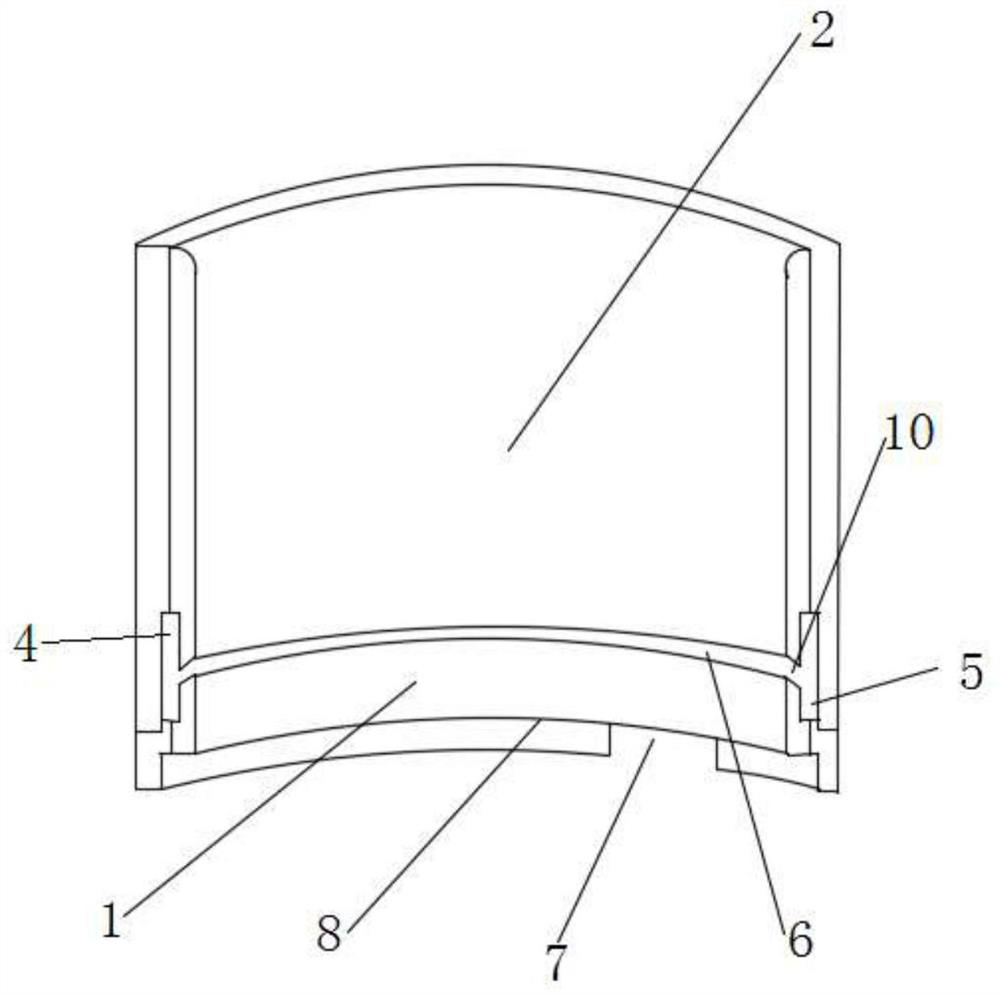

[0031]Such asfigure 1 ,figure 2 withFigure 4 As shown,figure 1 It is a schematic diagram of the structure of the installation components of the air cylinder in the first embodiment of the present invention.figure 2 It is a schematic diagram of the assembled structure of a blower in the specific embodiment of the present invention,figure 2 Mainly means to describe the shape after assembly, part of the structure is not infigure 2 In the presentation. The embodiment of the present invention discloses a wind cylinder, which includes a first sleeve and a first sleeve. The first sleeve 1 and the second sleeve 2 are connected up and down to each other, and an outer surface of the second sleeve 2 is provided. Air inlet 3. Wherein, the first sleeve 1 includes a first installation component 1a and a second installation component 2a, the first installation component 1a and the second in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com