Method for manufacturing micro-pile stack structure holographic laser

A production method and stack structure technology are applied in the field of micro-stack stack structure holographic laser production, which can solve the problems of slow exposure, low image pixels, and inconvenient anti-counterfeiting identification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

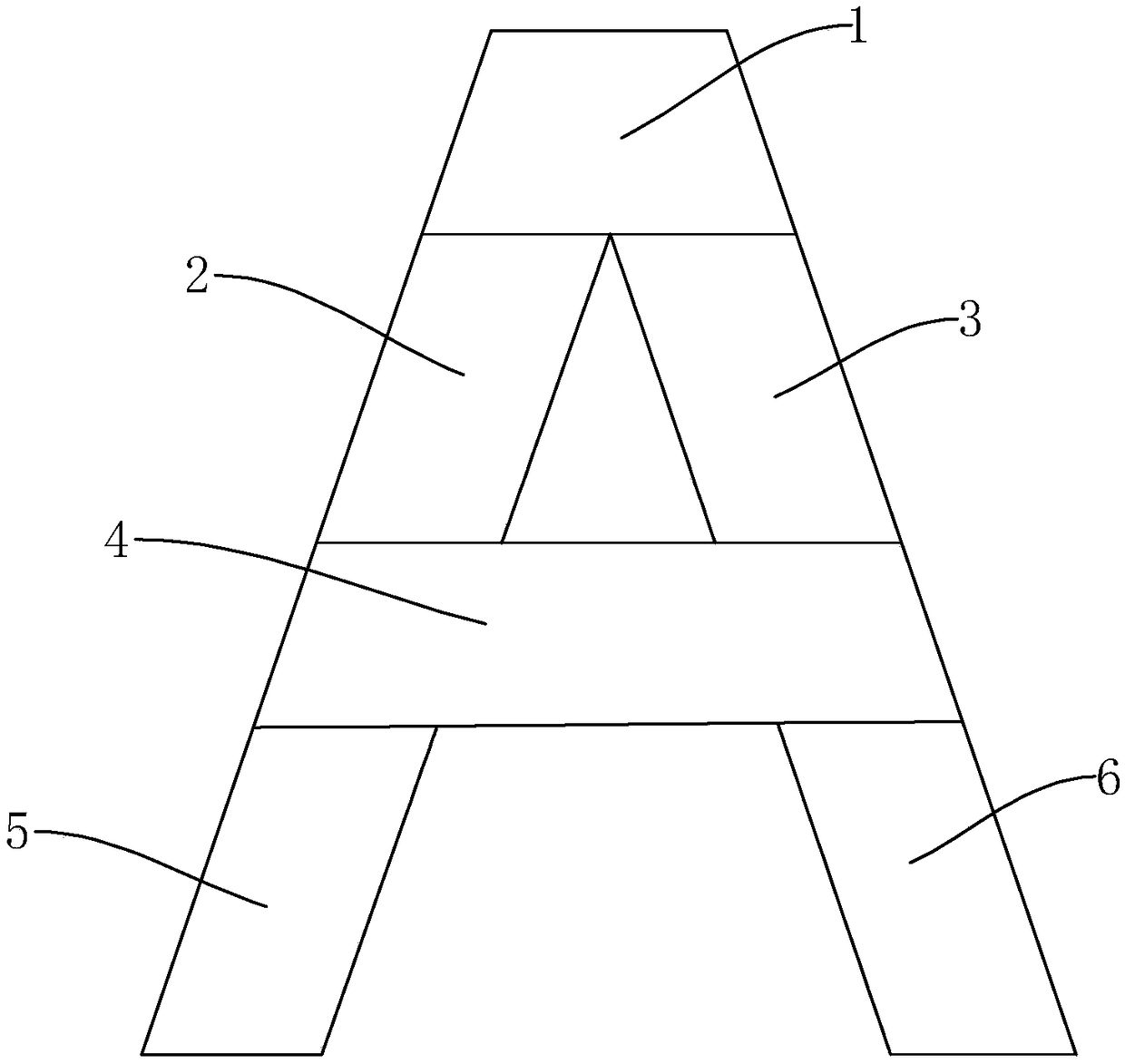

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0035] A method for manufacturing a holographic laser with a micro-stack stack structure, comprising the following steps:

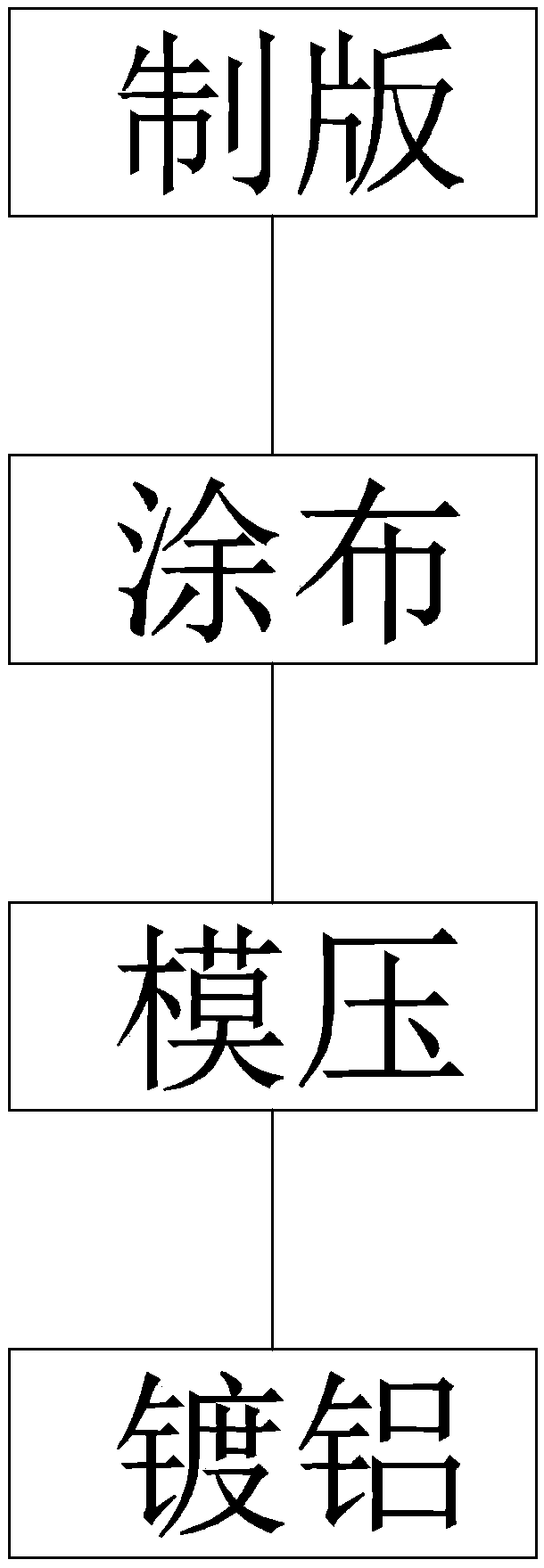

[0036] S1. Plate making: photolithography is carried out on the photosensitive plate by laser beam to form a laser pattern, and then the pattern is displayed by adding a developer; and then a metal layer is formed on the surface by silver spraying or silver plating to form a metal pattern , and finally nickel-plate the metallized photosensitive plate by electrolysis, and the formed nickel plate is used as the master plate, and then the nickel plate is copied by electroforming to form a sub-plate;

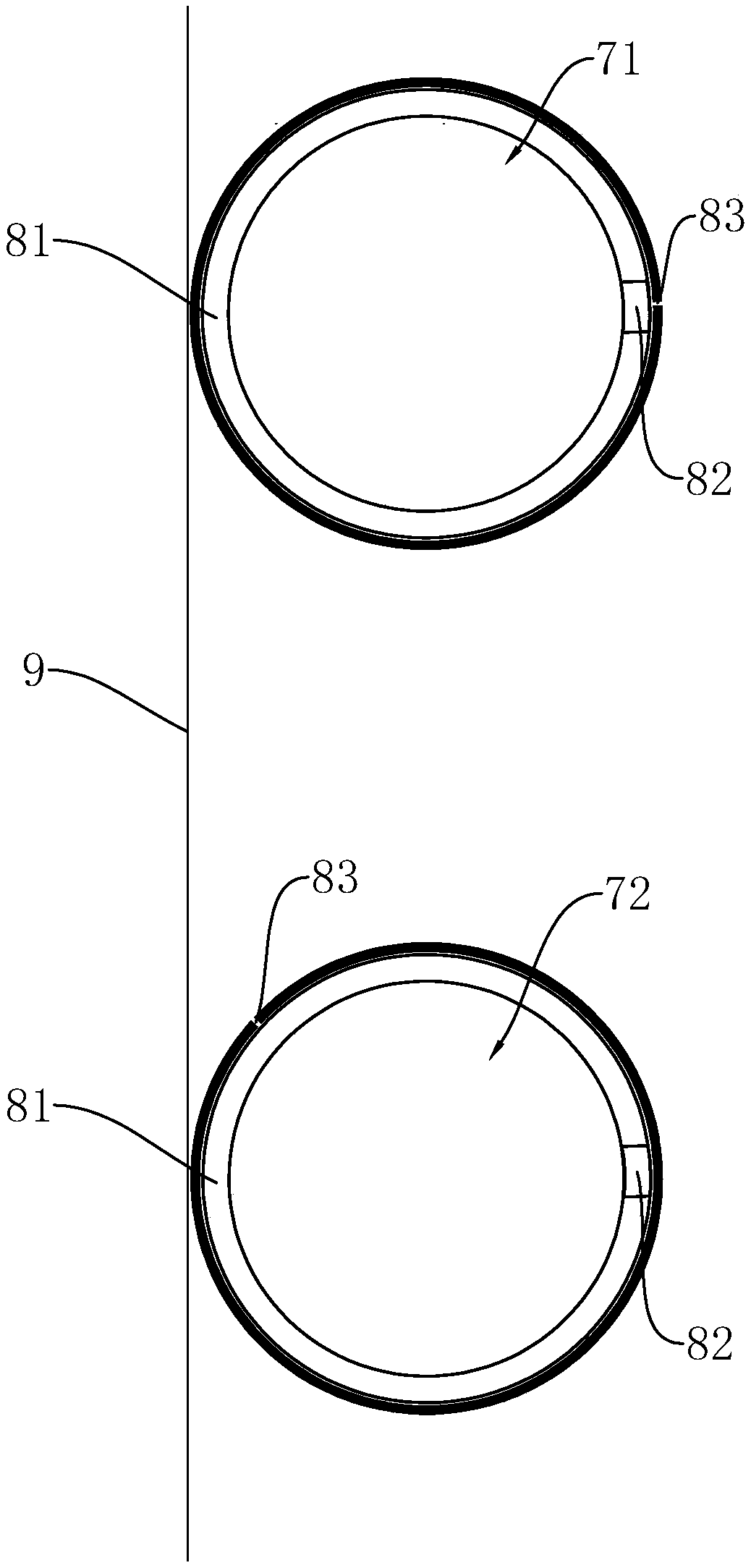

[0037] S2. Coating: Prepare the coating and apply it evenly on the base film 9 through a coating machine. The coating is generally made of resin suitable for molding, and the base film 9 can be made of materials such as PET, BOPP or PVC. constitute; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com