Environment-friendly treatment and resource utilization method for cyanide tailings

A technology for harmless treatment and cyanidation of tailings, applied in chemical instruments and methods, process efficiency improvement, solid separation, etc. The effect of improving yield and product quality, and shortening the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

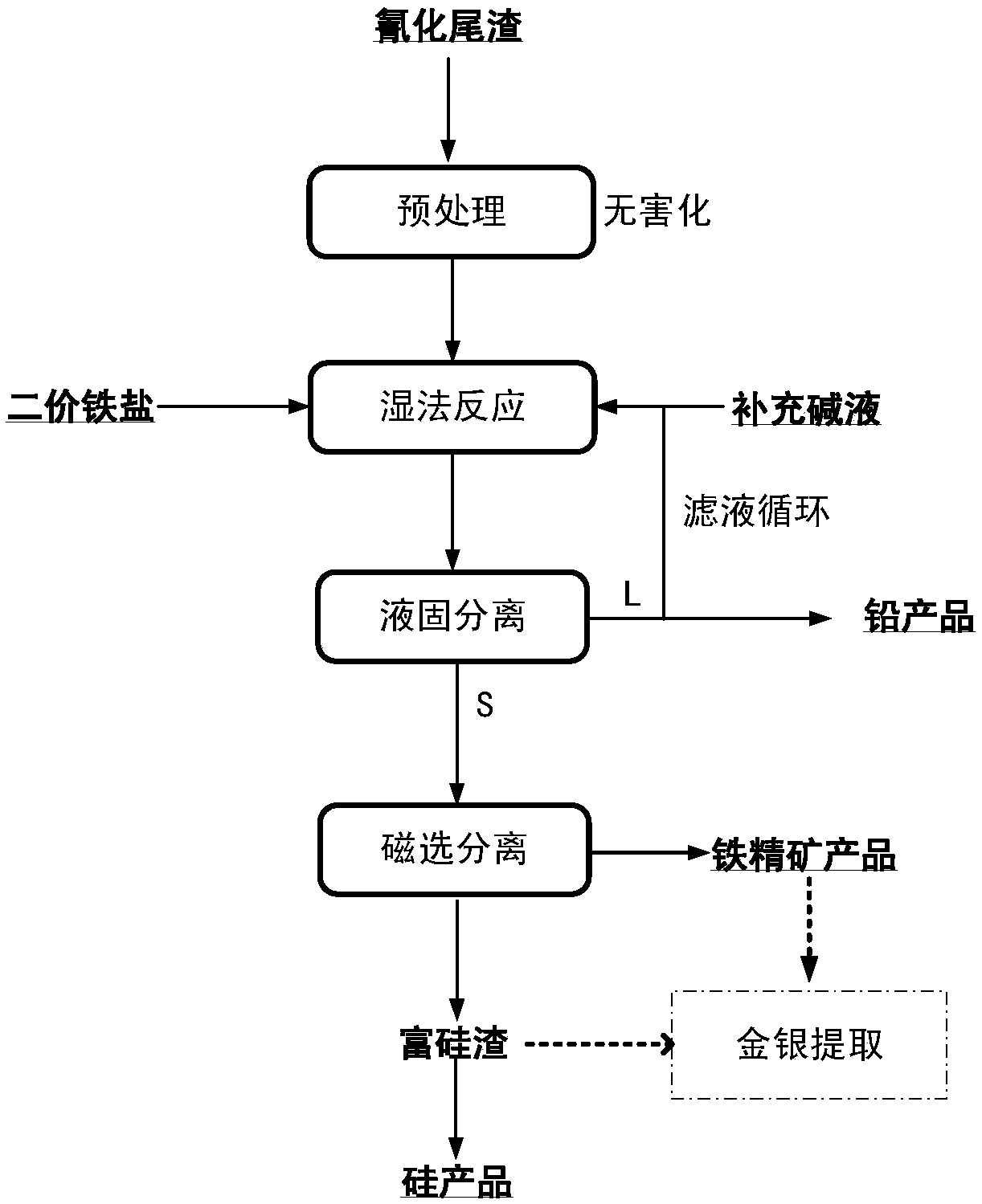

[0054] Such as figure 1 As shown, the method for harmless treatment and resource utilization of cyanide tailings provided in this embodiment includes the following steps:

[0055] (1) Mix 50g cyanide tailings with 45.61g FeSO 4 ·7H 2 O and 250mL sodium hydroxide solution (sodium hydroxide concentration is 50wt%) are mixed in autoclave, seal reactor, start timing when being heated to 120 ℃, leave kettle after reacting 7h under stirring state, filter, obtain leaching solution and reaction slag ;

[0056] (2) Wash the reaction slag obtained in step (1) with water, place it in an oven and dry it at 80°C for 24 hours, perform magnetic separation after grinding, and obtain iron concentrate and silicon-rich material, and use the cyanide leaching method to leach the iron concentrate recovery of gold and silver;

[0057] (3) Enrich the lead in the leach solution obtained in step (1) to a concentration of 20g / L, then reclaim lead by cooling and crystallization, add 1wt% lead oxide c...

Embodiment 2

[0060] The method for harmless treatment and resource utilization of cyanide tailings provided in this embodiment comprises the following steps:

[0061] (1) Mix 50g cyanide tailings with 45.61g FeSO 4 ·7H 2 O and 350mL sodium hydroxide solution (sodium hydroxide concentration is 40wt%) are mixed in the autoclave, pass into nitrogen to evacuate the air, start timing when heated to 90°C, leave the still after stirring for 12h, filter to obtain the leachate and reaction slag;

[0062] (2) Wash the reaction slag obtained in step (1) with water, put it in an oven and dry it at 80°C for 24 hours, and then conduct magnetic separation after grinding to obtain iron concentrate and silicon-rich material. Prepared as sodium silicate product;

[0063] (3) enrich the lead in the leaching solution that step (1) obtains to concentration to be 35g / L, then adopt the mode of cooling crystallization to reclaim lead, add the lead oxide crystal seed of 0.5wt% in the cooling process, the coolin...

Embodiment 3

[0066] The method for harmless treatment and resource utilization of cyanide tailings provided in this embodiment comprises the following steps:

[0067] (1) Mix 25g cyanide tailings with 20.78g FeCl 2 And 350mL sodium hydroxide solution (sodium hydroxide concentration is 10wt%) mixes in the autoclave, passes into nitrogen and evacuates the air, starts timing when heating to 180 ℃, leaves the kettle after reacting 5h under stirring state, filters, obtains leachate and Reaction slag;

[0068] (2) Wash the reaction slag obtained in step (1) with water, put it in an oven and dry it at 80°C for 24 hours, and then conduct magnetic separation after grinding to obtain iron concentrate and silicon-rich material. The material is prepared as a silicon fertilizer product;

[0069] (3) Enrich the lead in the leaching solution obtained in step (1) to a concentration of 15g / L, then reclaim lead by cooling and crystallization, add 5wt% lead oxide crystal seeds during the cooling process, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap