Stripped dyeing and colorful yarn production device and technology

A production device, multi-colored yarn technology, applied in the direction of yarn, spinning machine, textile and paper making, can solve pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

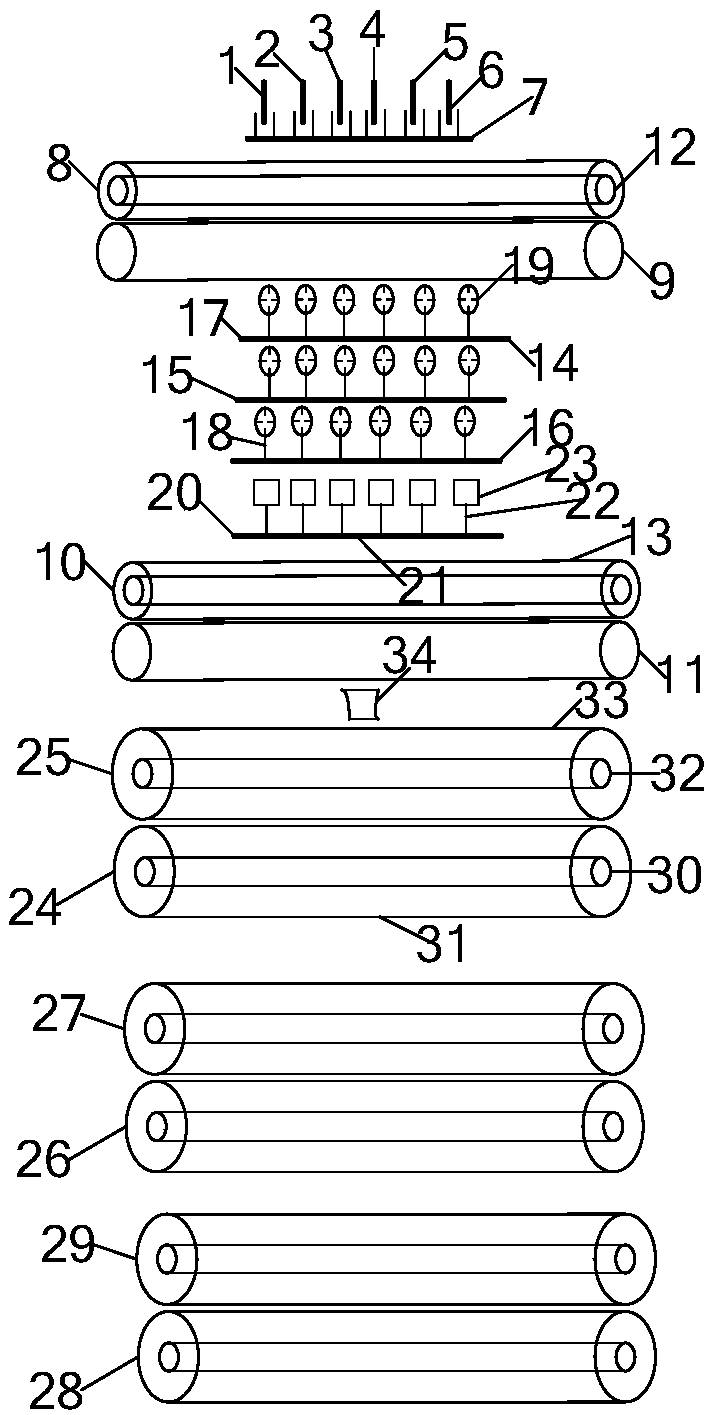

Embodiment 1

[0029] Strip dyed colorful yarn production device, the device includes a drafting system, the drafting system adopts a three-roller drafting structure, which includes a rear roller drafting pair composed of a rear bottom roller 24 and a rear top rubber roller 25, and a middle and bottom roller 26 and middle upper rubber roller 27 constitute the middle roller drafting pair, and the front roller drafting pair composed of the front bottom roller 28 and the front upper rubber roller 29; The system includes a pair of input and finishing pressing rollers and a pair of output and finishing pressing rollers, wherein the pair of input and finishing pressing rollers includes an input and finishing lower pressing roller 9 and an input and finishing upper pressing roller 8, and the pair of output and finishing pressing rollers includes an output and finishing lower pressing roller 11 and the output finishing press roller 10; the rear portion of the input and finishing press roller pair is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com