Temporary oil adding device applicable to hard asphalt mixture and construction method of temporary oil adding device

A technology of adding devices and hard asphalt, which is applied in the direction of roads, road repairs, roads, etc., can solve problems such as easy loosening, lower road service level, and molding effects that do not meet the requirements, and achieve the effect of improving crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation link of the temporary oil content adding device of the present invention is:

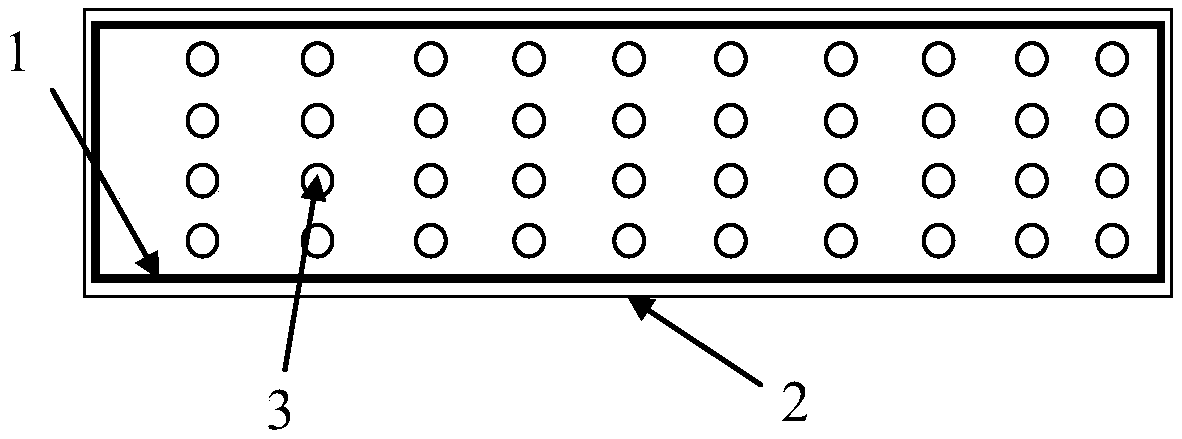

[0041] (1) Since the temperature of the hard asphalt mixture in the compaction and molding stages is about 150 degrees, in order to avoid the melting of the device under high temperature conditions, the hollow oil pipe 1 ( Plastic products made of PP or PET can be selected), and the length of the oil pipe 1 ranges from 0.5m to 5m (determined reasonably according to the paving width or road width during the project). The inner diameter of the oil pipe 1 ranges from 5 mm to 10 mm.

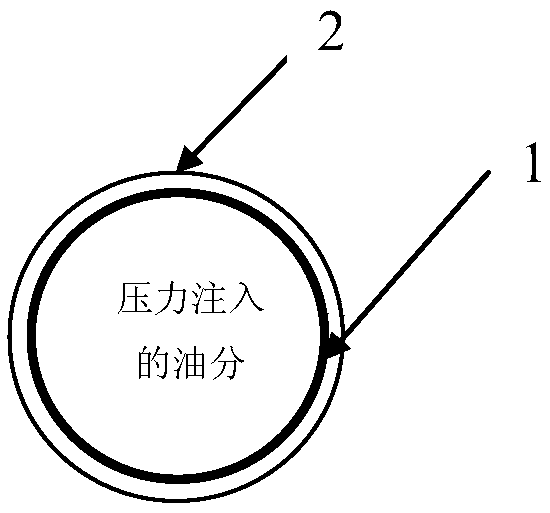

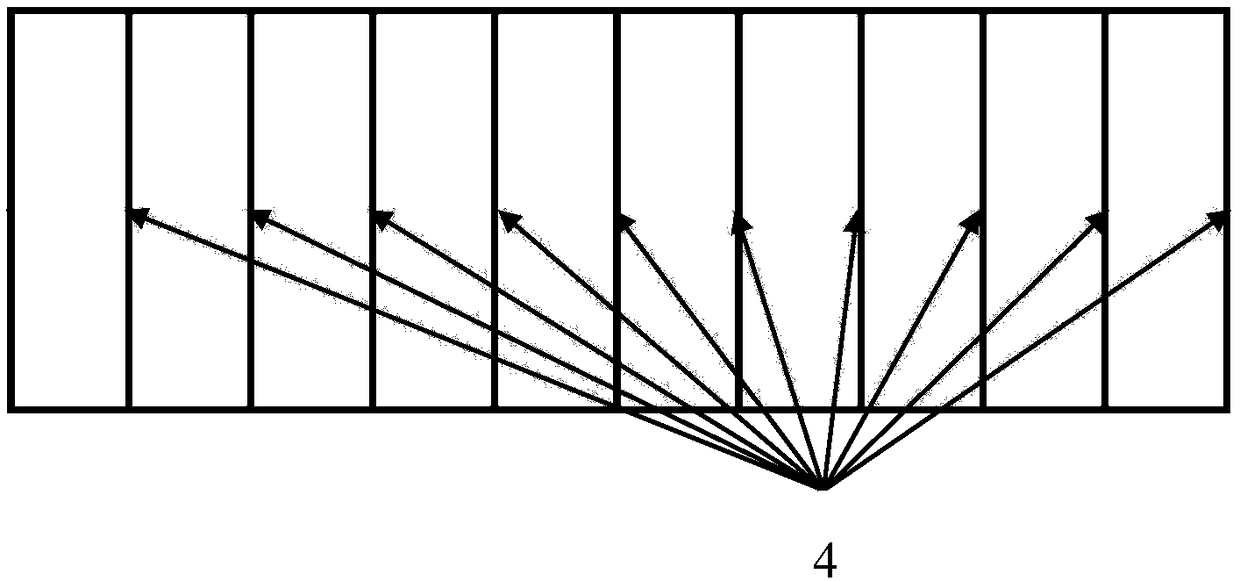

[0042](2) Make circular holes 3 with a diameter of 2-4 mm at intervals of 3-5 mm on the wall of the oil pipe 1 . Under the pressure of the road roller, the oil in the lumen of the oil pipe 1 can be sprayed out through the hole 3 and enter the pores of the hard asphalt mixture, thereby softening the asphalt, improving the working performance of the asphalt, and delaying the formation of the hard asph...

Embodiment 1

[0056] The length of the temporary oil addition device is 4.5m, the inner diameter is 7mm, the hole interval is 3mm, and the hole diameter is 2mm. The oil in the lumen is specifically diesel oil, the pipe wall material is PP plastic, and the surrounding soft plastic is UPVC material. . The interval between two temporary oil addition devices is 40cm. It is set at the middle depth of the lower layer of the road surface, and the thickness of the lower layer is 8cm. One-time paving width is 4.5m.

[0057] The construction condition is hard 30# asphalt mixture, the on-site paving temperature is 150°C, and the initial roller is 10 tons. Comparing the compactness and splitting strength of the asphalt pavement with this technology and the mixture without this technology, the following technical parameters are obtained

[0058] Table 1 Comparison of compaction splitting strength

[0059] Mixture category

Embodiment 2

[0061] The length of the temporary oil addition device is 3m, the inner diameter is 5mm, the hole interval is 5mm, and the hole diameter is 3mm. The oil in the tube cavity is divided into filtered waste oil. The material of the tube wall is PET plastic, and the surrounding soft plastic is UPVC. material. The interval between two temporary oil adding devices is 45cm. Set on the surface layer of the road surface, the thickness of the surface layer is 6cm, and the device is set at the middle depth of the surface layer. The one-time paving width is 6m, and two basic devices are installed within the paving width at the same time.

[0062] The construction condition is hard 50# asphalt mixture, the on-site paving temperature is 150°C, and the initial roller is 10 tons. Comparing the compactness and splitting strength of the asphalt pavement with this technology and the mixture without this technology, the following technical parameters are obtained

[0063] Table 2 Comparison of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Inner diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com