Assembled integral type basement structure and safe and quick construction method

A basement, integrated technology, applied in underwater structures, infrastructure projects, artificial islands, etc., can solve the problems of difficult anti-floating stability, poor thermal and sound insulation performance, delayed construction period and other problems in the basement, saving construction templates, The effect of labor reduction and cross-work convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

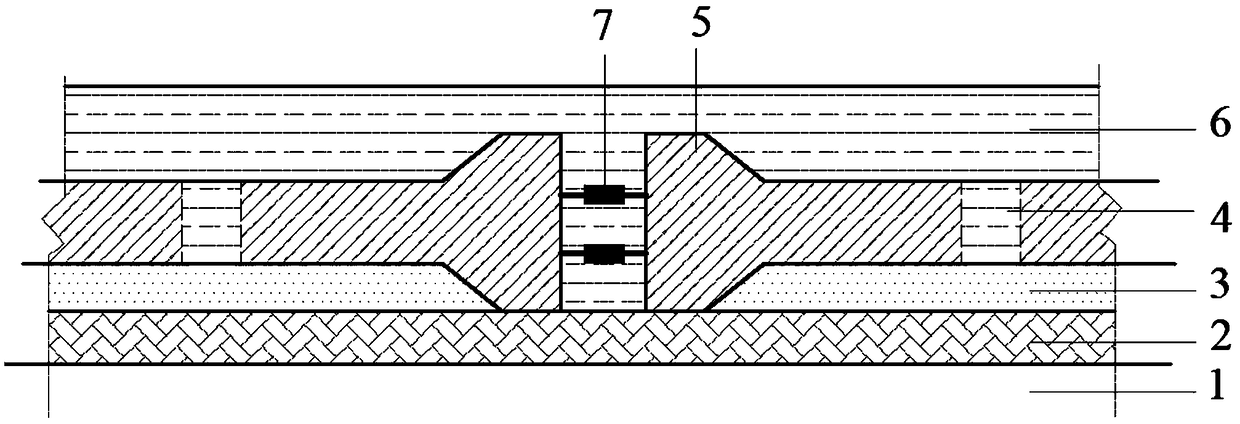

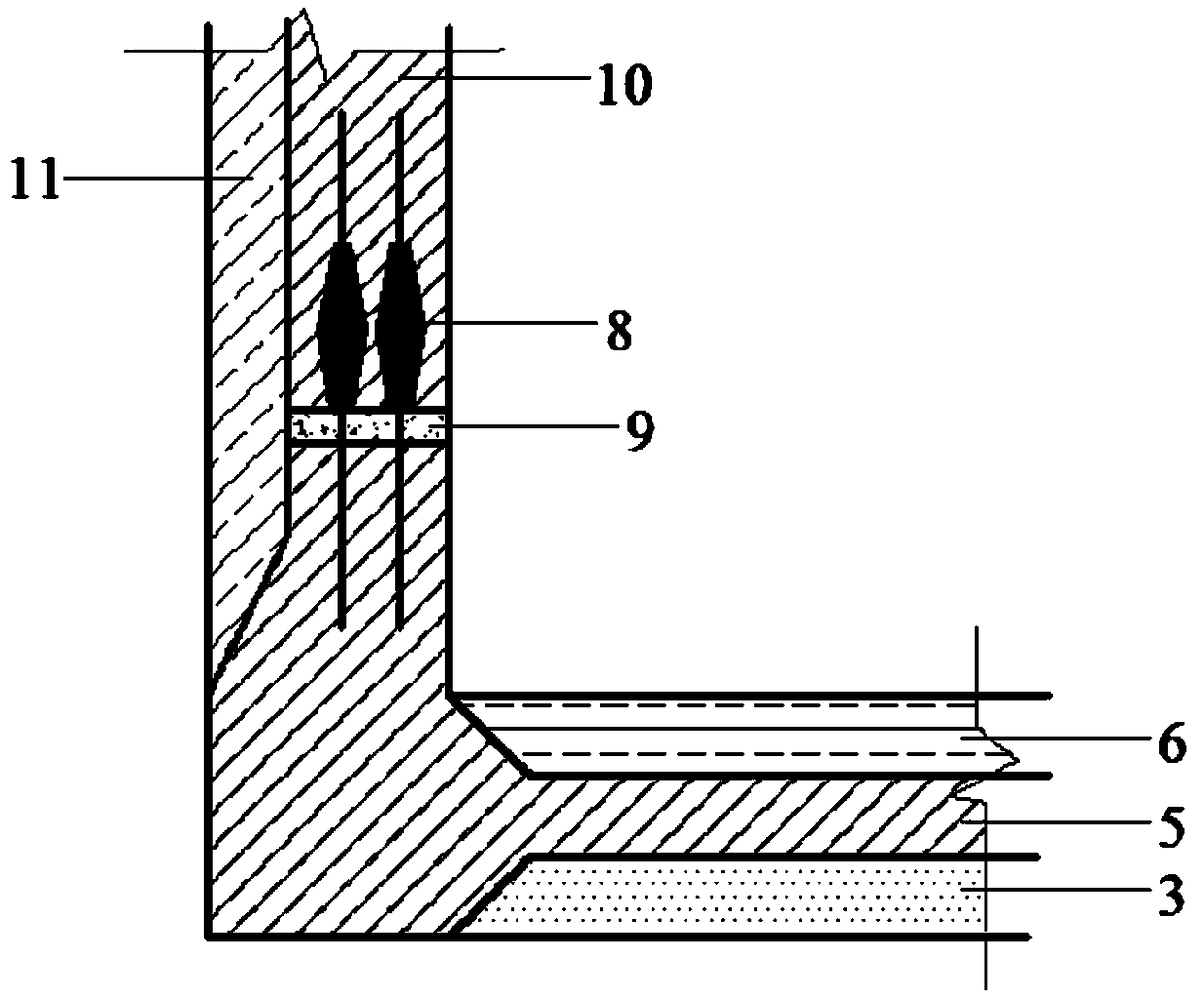

[0040] The invention provides an assembled integral basement structure and its fast and safe construction method, see Figure 1-3 , including: plain concrete cushion 2, prefabricated floor 5, prefabricated exterior wall 10;

[0041] The plain concrete cushion 2 is set on the foundation 1 of the predetermined foundation pit and the waterproof coiled material is laid; the prefabricated base plate 5 is installed on the waterproof coiled material; the prefabricated base plates 5 are connected vertically and horizontally; the outer The edge prefabricated bottom plate 5 is connected with the prefabricated exterior wall 10; the lower surface of the prefabricated bottom plate 5 is provided with post-grouting concrete 3, and the upper surface of the prefabricated bottom plate 5 is provided with a cast-in-place concrete bottom plate laminated layer 6.

[0042] Further, the longitudinal and transverse sections of the prefabricated bottom plate 5 can be made in the form of "—", "︺", "hori...

Embodiment 2

[0047] On the other hand, it provides a fast and safe construction method for an assembled monolithic basement, including:

[0048] Set plain concrete cushion on the predetermined foundation and lay waterproof membrane;

[0049] Install and connect the prefabricated floor on the paved waterproof membrane.

[0050] Connect the prefabricated bottom slab at the edge of the basement with the prefabricated exterior wall;

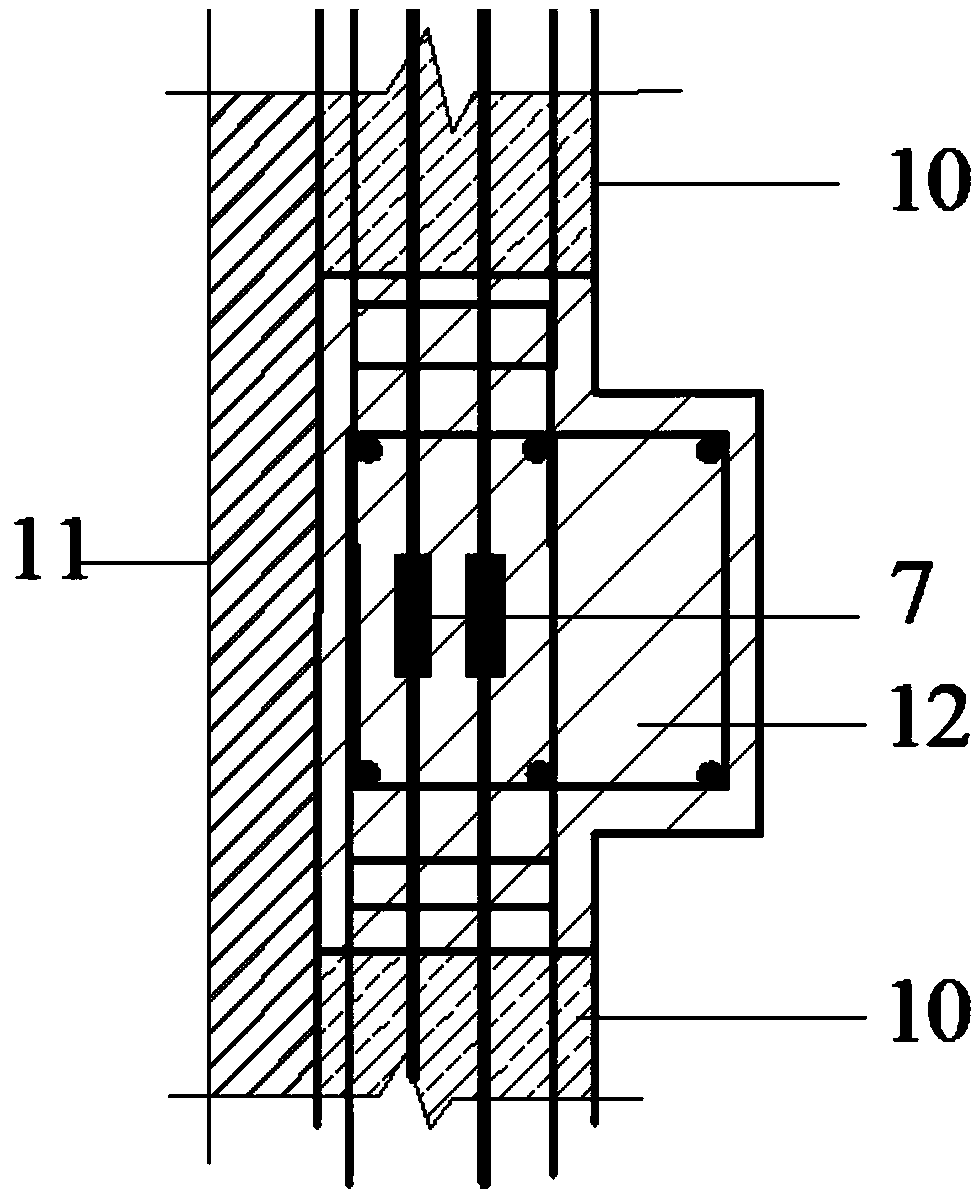

[0051] Connect the prefabricated exterior walls of the basement with cast-in-place concrete columns;

[0052] Connect basement prefabricated roof beams with cast-in-place concrete columns;

[0053] Connect basement precast roof with precast roof beams.

[0054] Further, the step of installing the laminated bottom plate on the set waterproof coiled material is as follows:

[0055] The prefabricated floor, cast-in-place reinforced concrete columns and foundation longitudinal reinforcements are mechanically connected by sleeves and wait for the cast-in-place concr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com