Intelligent well drilling system and method

An intelligent and drilling technology, which is applied to the automatic control system of drilling, drilling equipment, directional drilling, etc., can solve the problems of high cost and increased drilling cycle, and achieve the effects of saving costs, realizing real-time monitoring, and improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

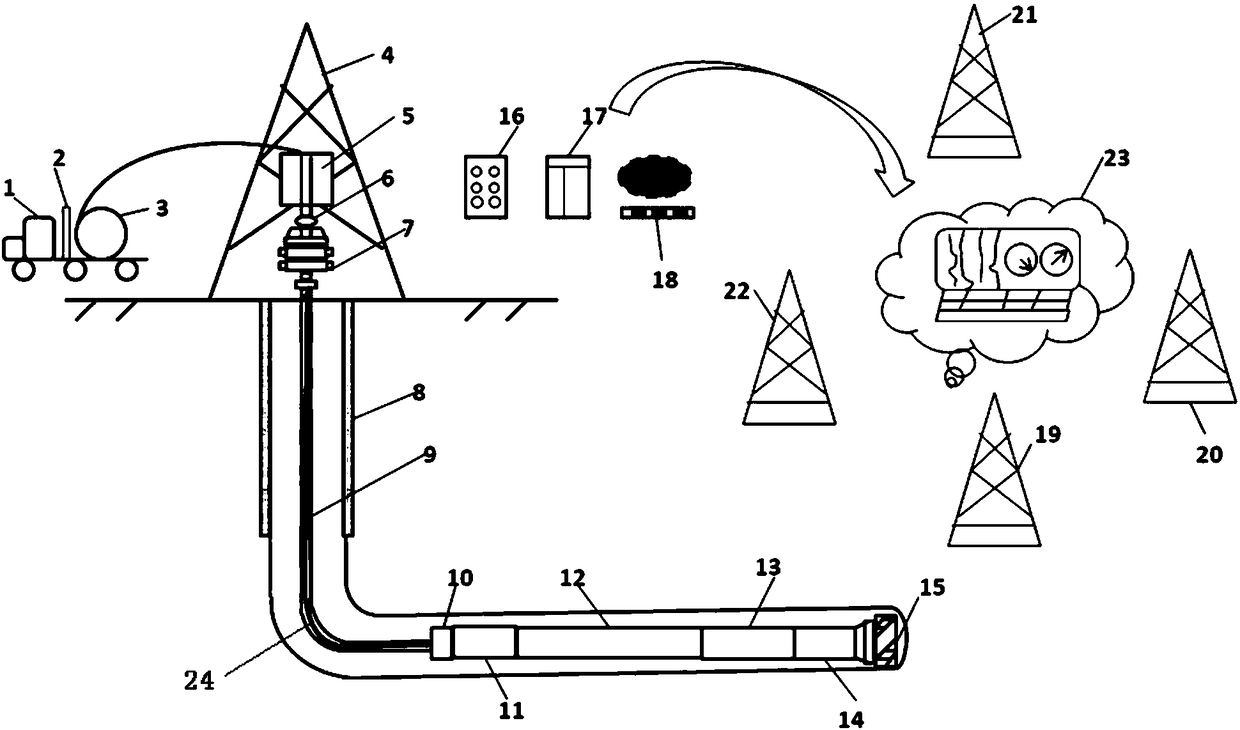

[0042] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0043] An intelligent drilling system, using coiled tubing to integrate remote control, data acquisition and real-time monitoring, correction of the system's intelligent drilling method, such as figure 1 As shown, it includes three parts, surface system, downhole system and intelligent drilling control platform 23 .

[0044] The ground system includes: coiled tubing unit 1, coiled tubing control platform 2, coiled tubing drum 3, casing running derrick 4, injection head 5, rotating control head 6, supporting blowout prevention equipment 7, wellhead pressure adjustment device 16, Power supply equipment 17, monitoring network 18.

[0045] The downhole system includes: coiled tubing with cables 9, optical fiber sensors 24, wet joints 10, intelligent pressurized shorts 11, closed-loop drilling systems 12, downhole motors 13, near-bit measurement and forward detection syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com