High pressure well sealing oil-water well pressure punching device and punching plugging device

A technology of drilling and sealing oil under pressure, which is applied in the directions of sealing/isolation, wellbore/well components, earthwork drilling and production, etc., and can solve problems such as drilling and sealing under pressure, so as to achieve convenient operation and prevent The effect of uncontrollable pressure leakage and ensuring the safety of well sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

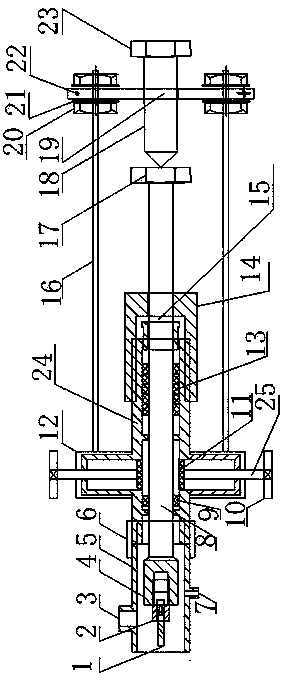

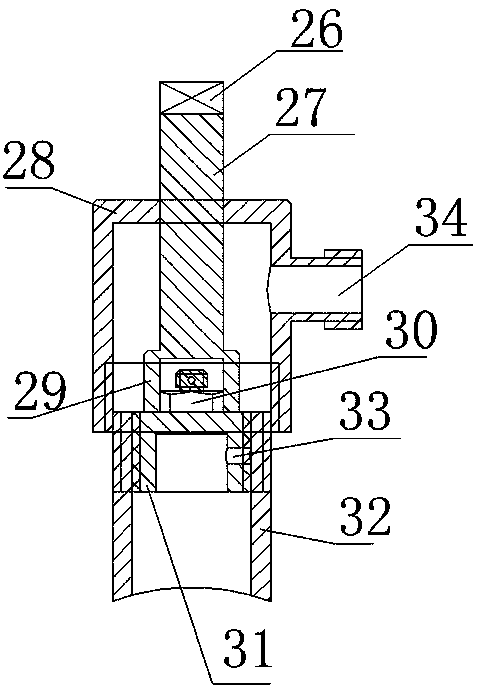

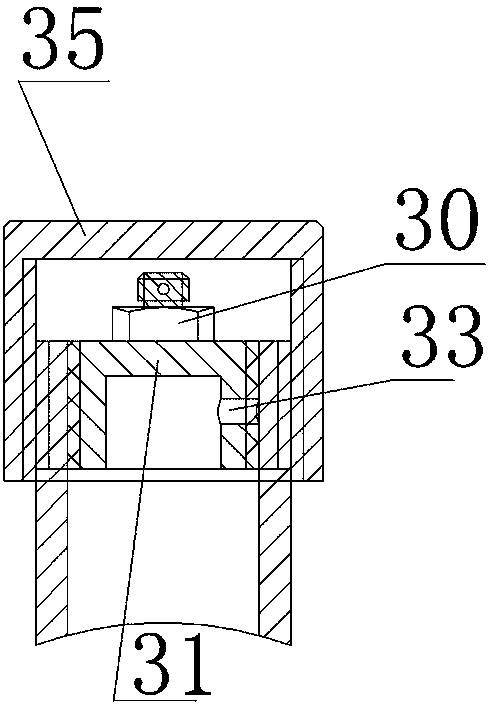

[0031] see figure 1 As shown, the high-pressure well sealing oil-water well drilling device of the present invention includes a drilling bit 1, a drill bit holder 2, a pressure relief port 3, a connecting wire head 4, a high-pressure sealing cabin body 5, a connecting clamp 6, Pressure gauge wire head 7, radial rotation rod 8, primary sealing assembly 9, hand wheel 10, sealing sheet 11, connecting ring 12, secondary sealing rubber ring 13, secondary sealing assembly 14, rubber ring gland 15, connection Screw mandrel 16, radial rotation nut 17, top screw mandrel 18, fixed plate 19, compression nut 20, stop washer 21, positioning pin hole 22, pressure force nut 23, housing 24 and rotating rod 25

[0032] The high-pressure sealed cabin body 5 is located at the front of the housing 24, and the high-pressure sealed cabin body 5 is connected to the housing 24 through the connecting clamp 6. The housing 24 is provided with a connecting ring 12, and the fixing plate 19 is located at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com