An improved idler set device for a slag cooler

A technology of idler group and slag cooler, which is applied to mechanical equipment, rotating bearings, shafts and bearings, etc. The problem of low force limit, etc., can reduce the probability of bearing damage, increase the axial force limit, facilitate jacking up and replace the idler parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

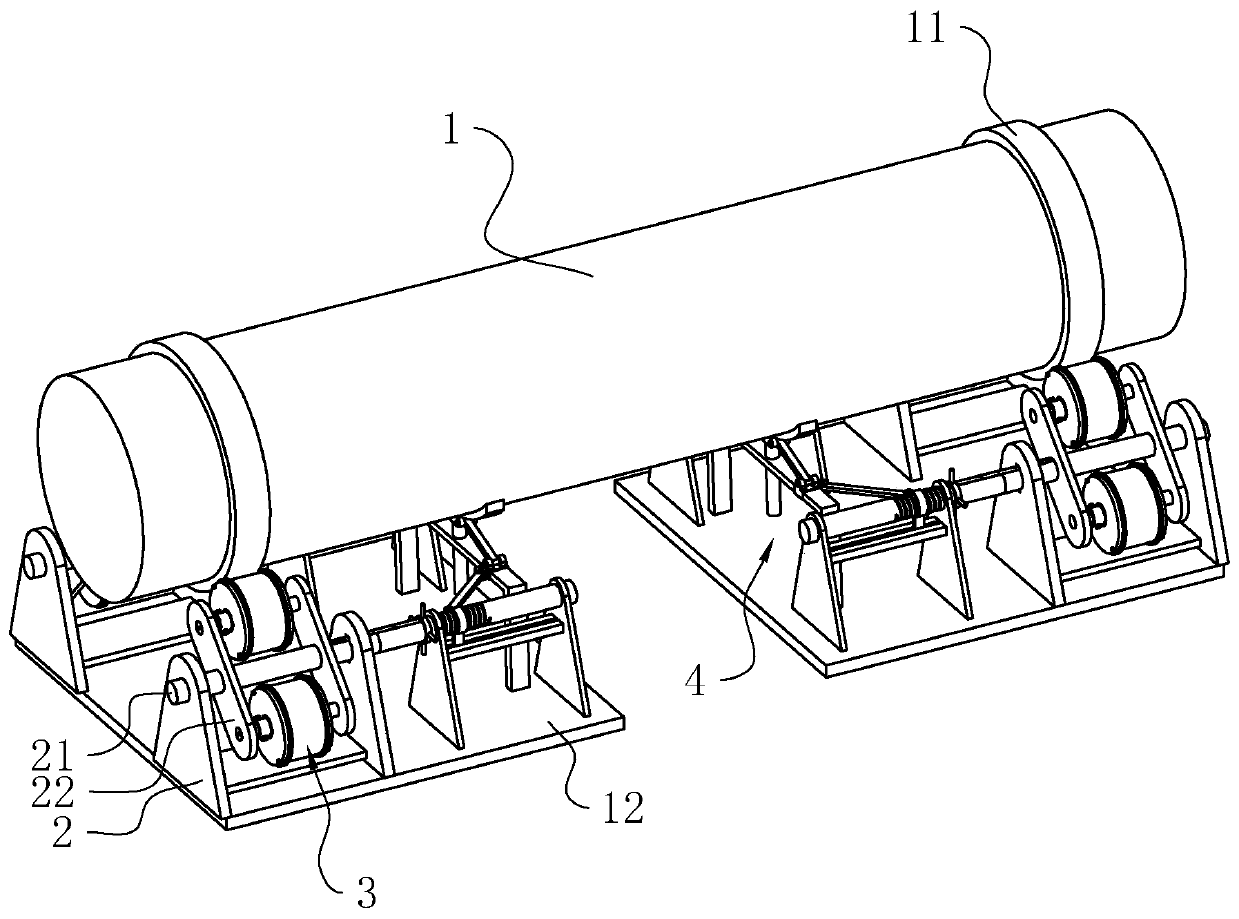

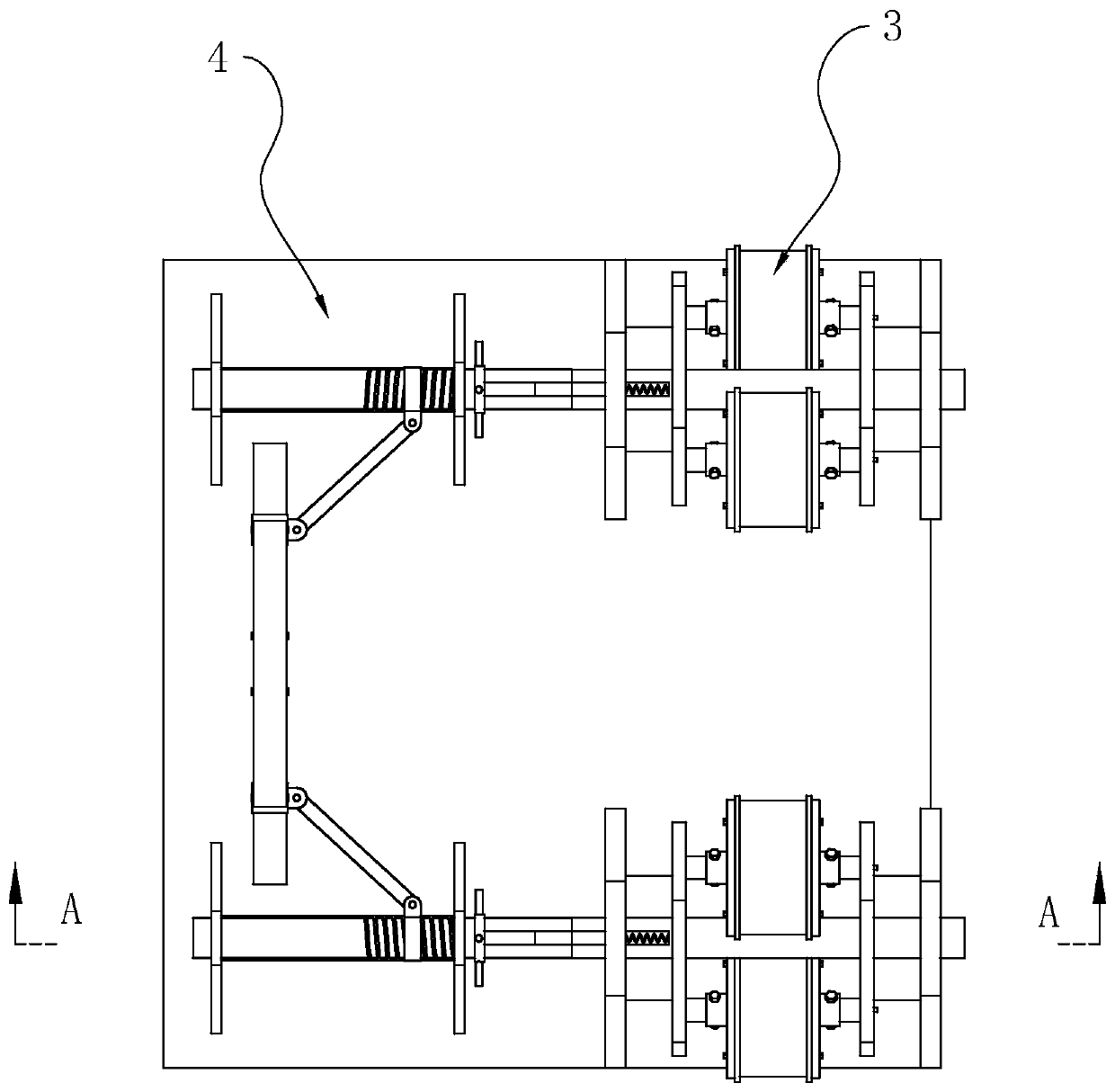

[0042] Example 1: An improved idler set device for a slag cooler, refer to figure 1 , including two bases 12, each base 12 corresponds to a support ring 11 on the drum 1. Two fixing frames 2 are fixed on the upper side of each base 12 , and the two fixing frames 2 are symmetrically located on both sides of the drum 1 along the axis of the drum 1 .

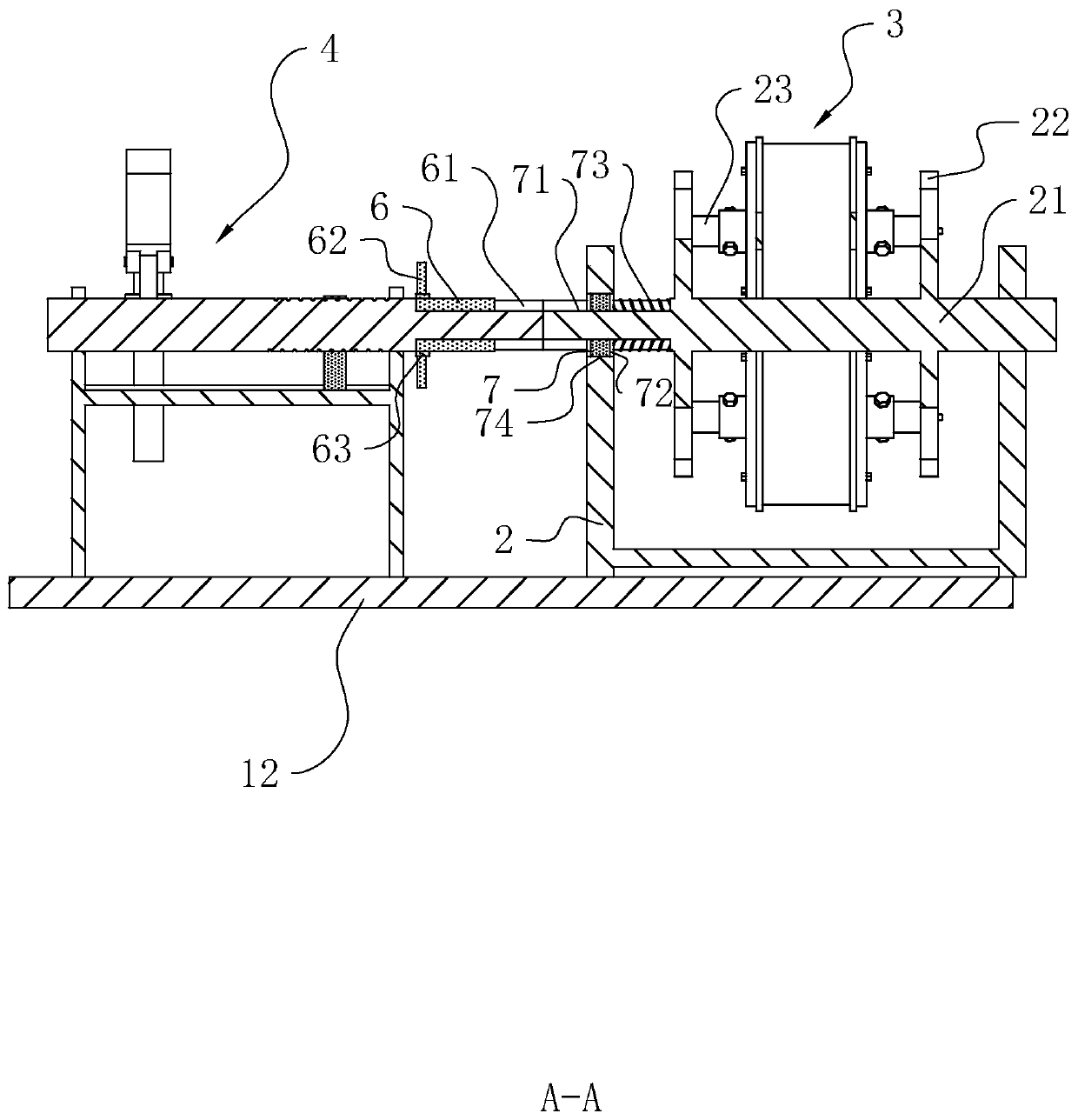

[0043] refer to Figure 4 and Figure 5 , a roller frame 22 is installed in each fixed frame 2, a main shaft 21 is fixedly worn on the roller frame 22, and two rotating holes 74 are provided on the fixed frame 2 (see image 3 ), the rotation at both ends of the main shaft 21 is embedded in the two rotations. The idler member 3 is arranged inside the idler frame 22 , and the idler member 3 can be used to abut against the support ring 11 . A rotating shaft 23 is pierced on the idler member 3 , and both ends of the rotating shaft 23 are rotatably connected to the idler frame 22 .

[0044] refer to image 3 and Figure 4 The out...

Embodiment 2

[0050] Embodiment 2, an improved idler set device for a slag cooler, refer to figure 1 , the difference from Embodiment 1 is that components such as the jacking assembly 4 are added.

[0051] refer to figure 1 , there are two idler elements 3 on each idler frame 22, and the axes of the two idler elements 3 and the axis of the drum 1 are in the same plane. When a certain idler 3 is damaged and needs to be replaced, the jacking assembly 4 can be moved upwards first, and withstand the drum 1, and then the main shaft 21 is rotated to make another idler 3 on the same idler frame 22 Instead of the damaged idler element 3 , it is in contact with the support ring 11 . Afterwards, the damaged roller member 3 can be disassembled and repaired, so that the entire drum 1 does not need to be hoisted, so as to improve the convenience of operation and work efficiency.

[0052] refer to Figure 4 , the jacking assembly 4 includes two separate columns in the drum 1 (see figure 1 ) jacking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com