Refrigerant charging method for water-cooled oil cooling refrigeration system

A refrigeration system and refrigerant technology, applied in the direction of refrigerants, refrigerators, refrigeration components, etc., can solve the problems of complex structure, ambiguous program rhythm, inconvenient operation, etc., and achieve high charging efficiency, clear program, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below with reference to the drawings and specific embodiments of the specification.

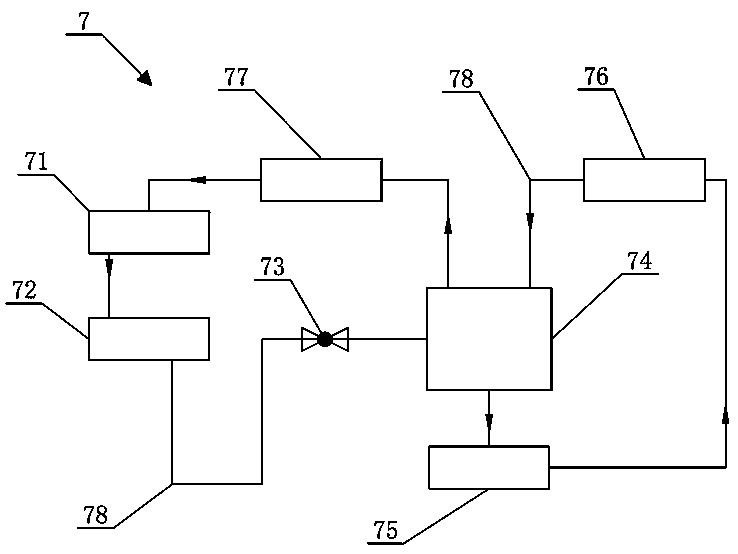

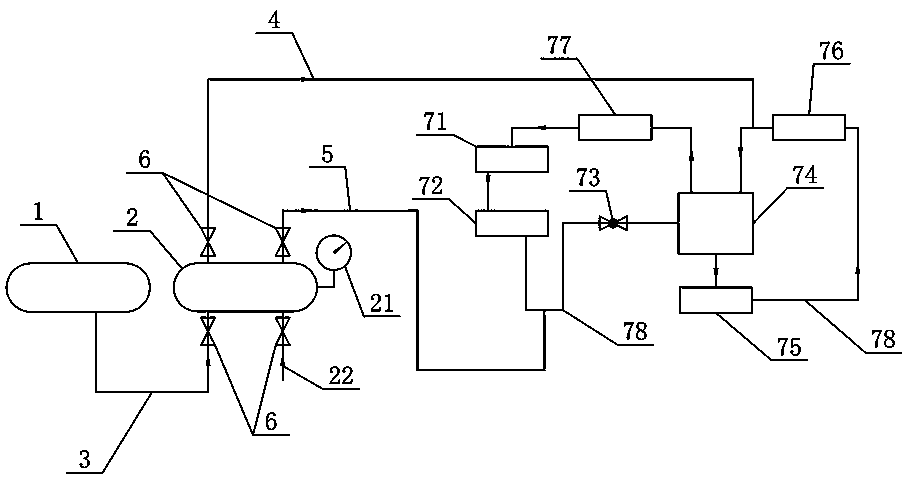

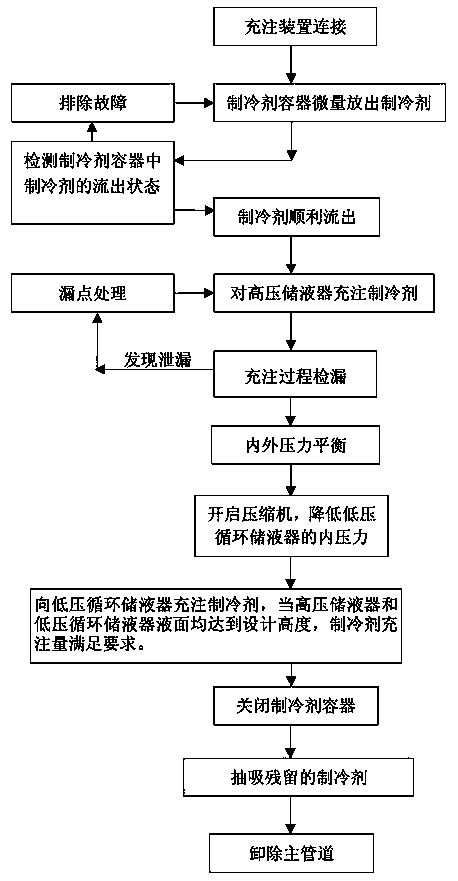

[0034] figure 2 with image 3 The refrigerant charging method of the water-cooled oil cooling refrigeration system of this embodiment is shown, and the charging method is mainly composed of the refrigerant container 1, the distribution station 2, the main pipe 3, the first distribution pipe 4 and the second distribution pipe 5. The device fills the water-cooled oil cooling refrigeration system 7 with refrigerant, the distribution station 2 is equipped with a pressure gauge 21, the refrigerant container 1 and the distribution station 2 are connected by the main pipe 3, and one end of the first distribution pipe 4 is connected to the distribution station 2. The other end is connected to the connecting pipe 78 between the low-pressure circulating accumulator 74 and the evaporator 76, one end of the second distribution pipe 5 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com