Freeze-drying machine plate layer temperature control method and system

A temperature control method and temperature control system technology, applied in drying, refrigerators, refrigeration components, etc., can solve the problems of uncontrollable temperature changes, affecting the freeze-drying process, and lack of cooling capacity of freeze-dryer cold traps, etc., to achieve control The effect of simple and efficient process and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

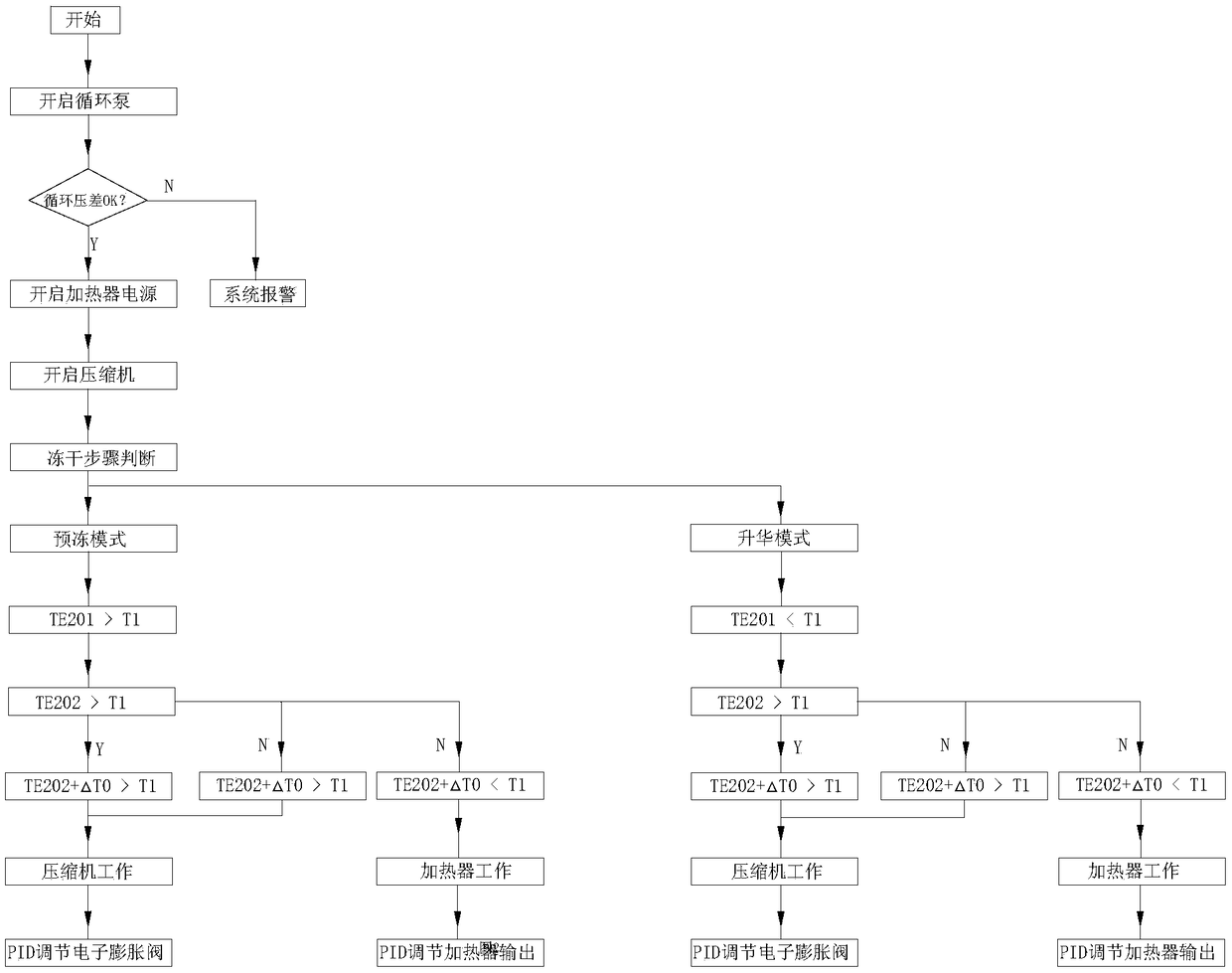

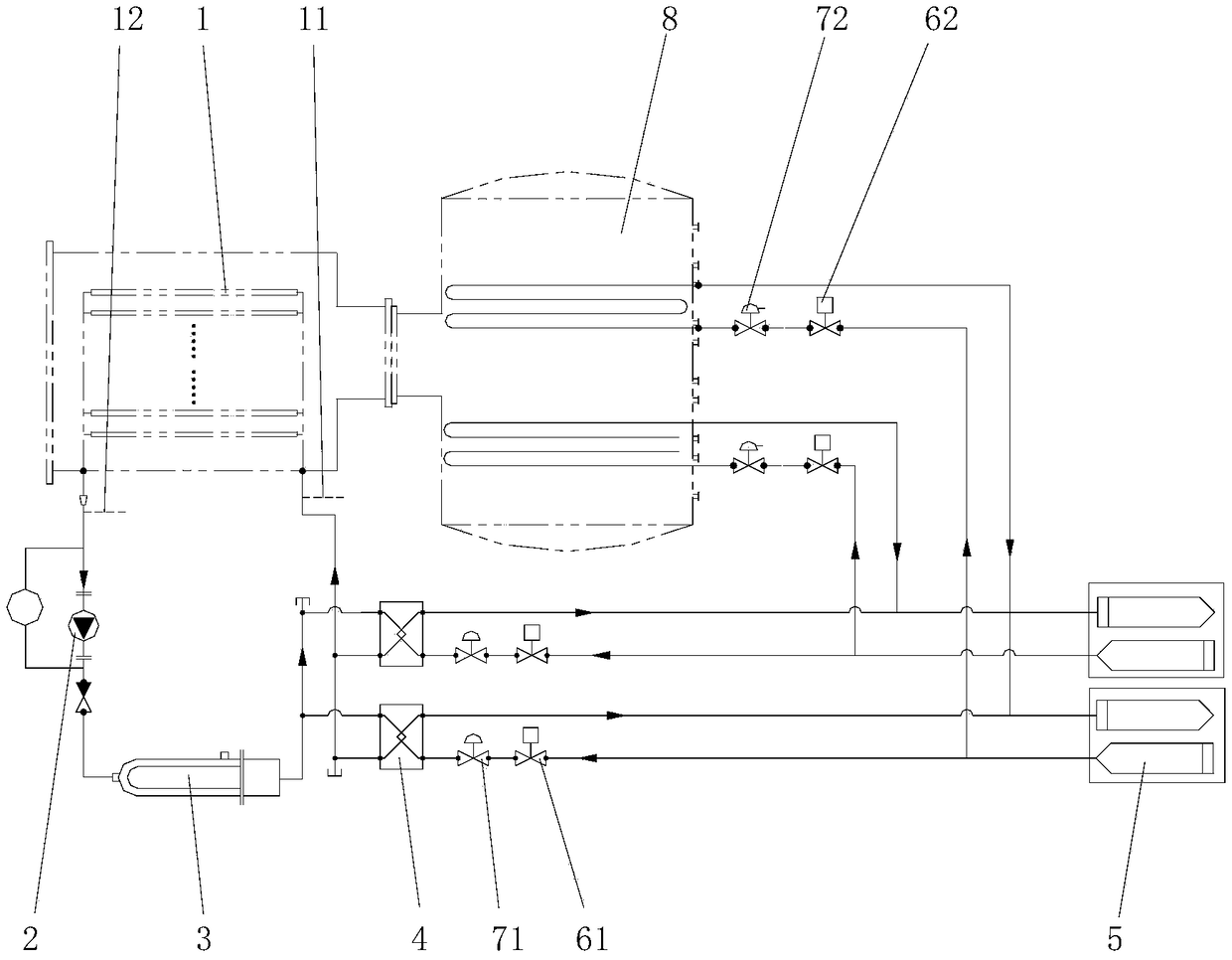

[0037] The flow chart of the freeze-dryer plate temperature control method of the present invention is as follows figure 1 Shown: in the method for controlling the plate temperature of the freeze dryer of the present invention, in the pre-freezing mode, the refrigeration compressor is controlled to work to cool the plate; in the sublimation mode, the heater is controlled to work to heat the plate; in the pre-freezing mode and In the sublimation mode, by comparing the detected temperature T2 at the plate outlet and the sum of the system temperature rise △T with the value of the set reference temperature value, it is judged whether the refrigeration compressor needs to work and whether the heater needs to work, so as to adjust the plate inlet. The detection temperature T1 is infinitely close to the set reference temperature T0. In the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com