Continuous welded rail temperature force and additional force testing method and system

A technology of a seamless track rail and a test method, applied in the field of rail transit, can solve the problems of increasing the difficulty of fiber grating layout, reducing the success rate of the separation test of the basic temperature force and the additional force, and inaccurate longitudinal force, so as to improve the test efficiency. , The effect of simplifying the structure and manufacturing process and reducing the test error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

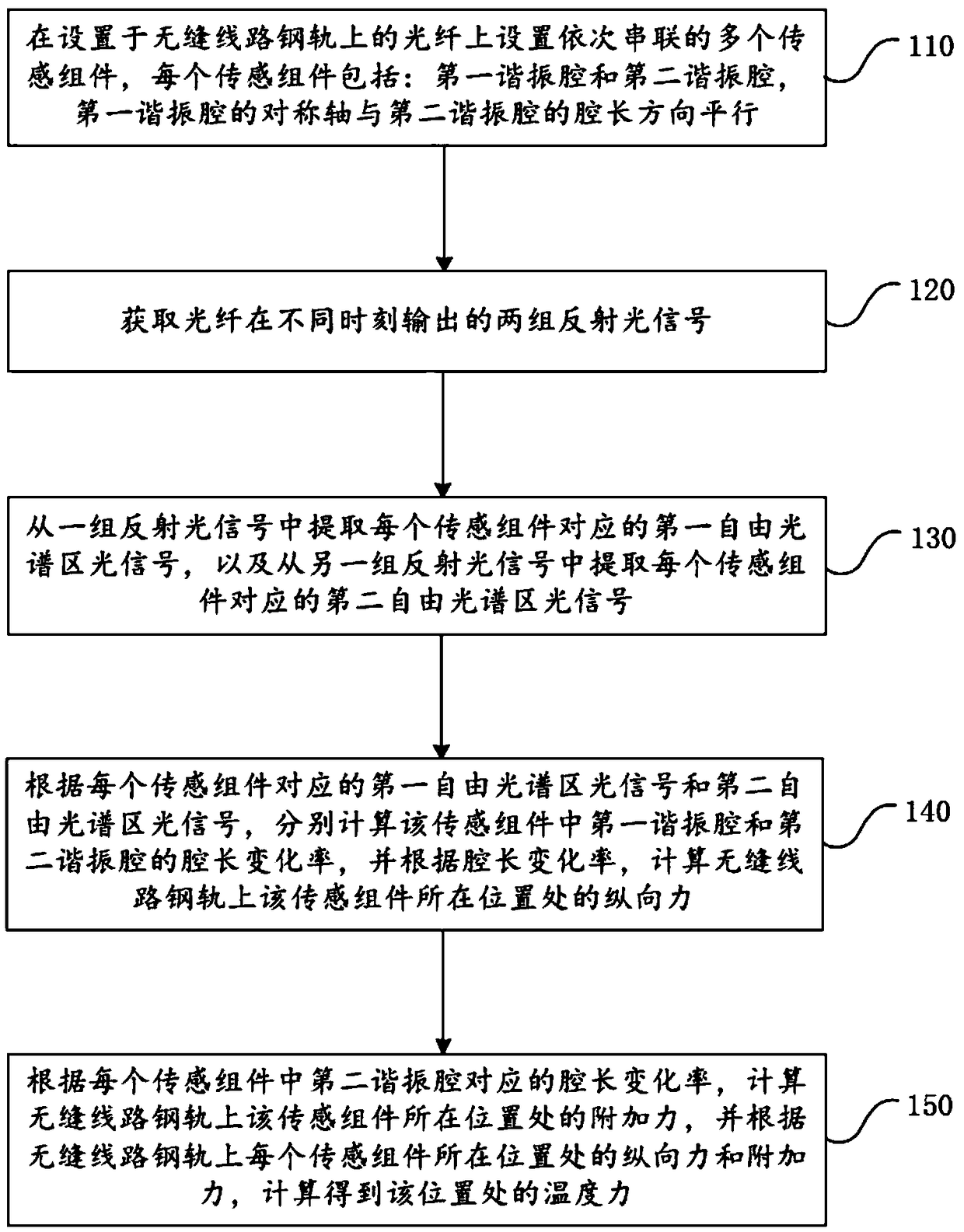

[0068] In this embodiment, a test method 100 for the temperature force and additional force of a seamless track rail includes:

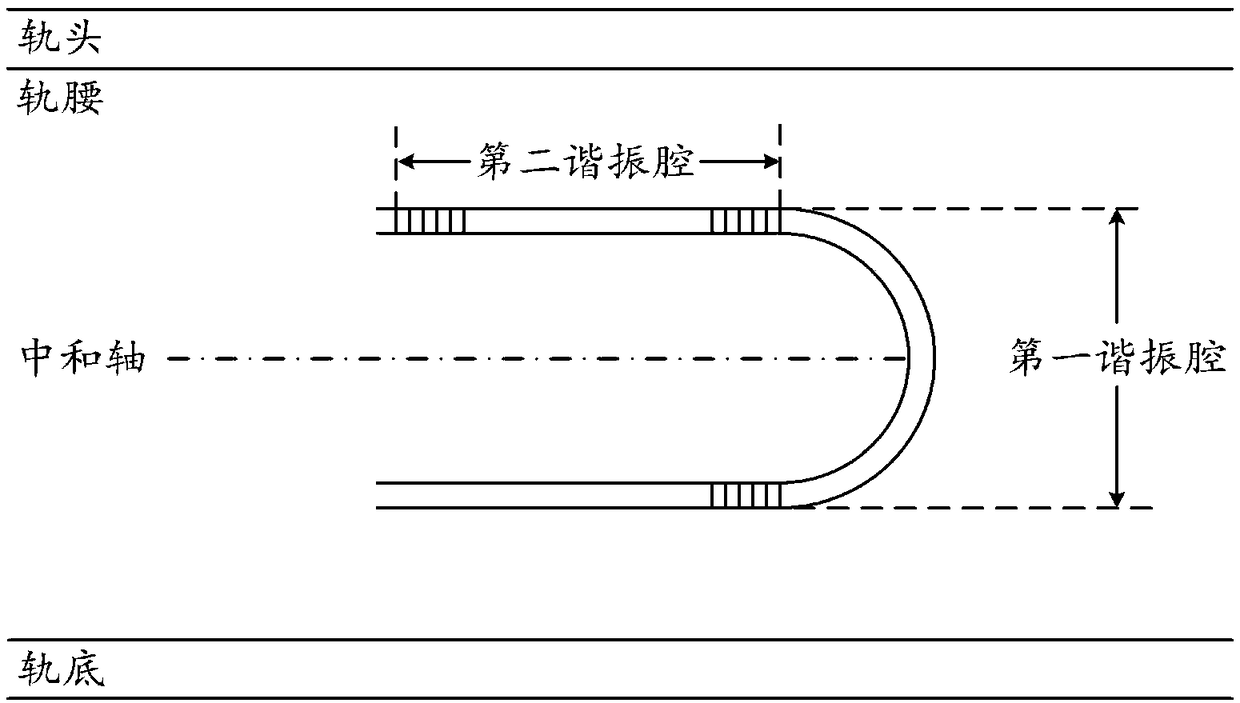

[0069] Step 110: Set a plurality of sensing components in series on the optical fiber arranged on the seamless line rail, each sensing component includes: a first resonant cavity and a second resonant cavity, and the symmetry axis of the first resonant cavity and the The cavity length direction of the second resonant cavity is parallel.

[0070] Step 120, acquiring two groups of reflected optical signals output by the optical fiber at different times.

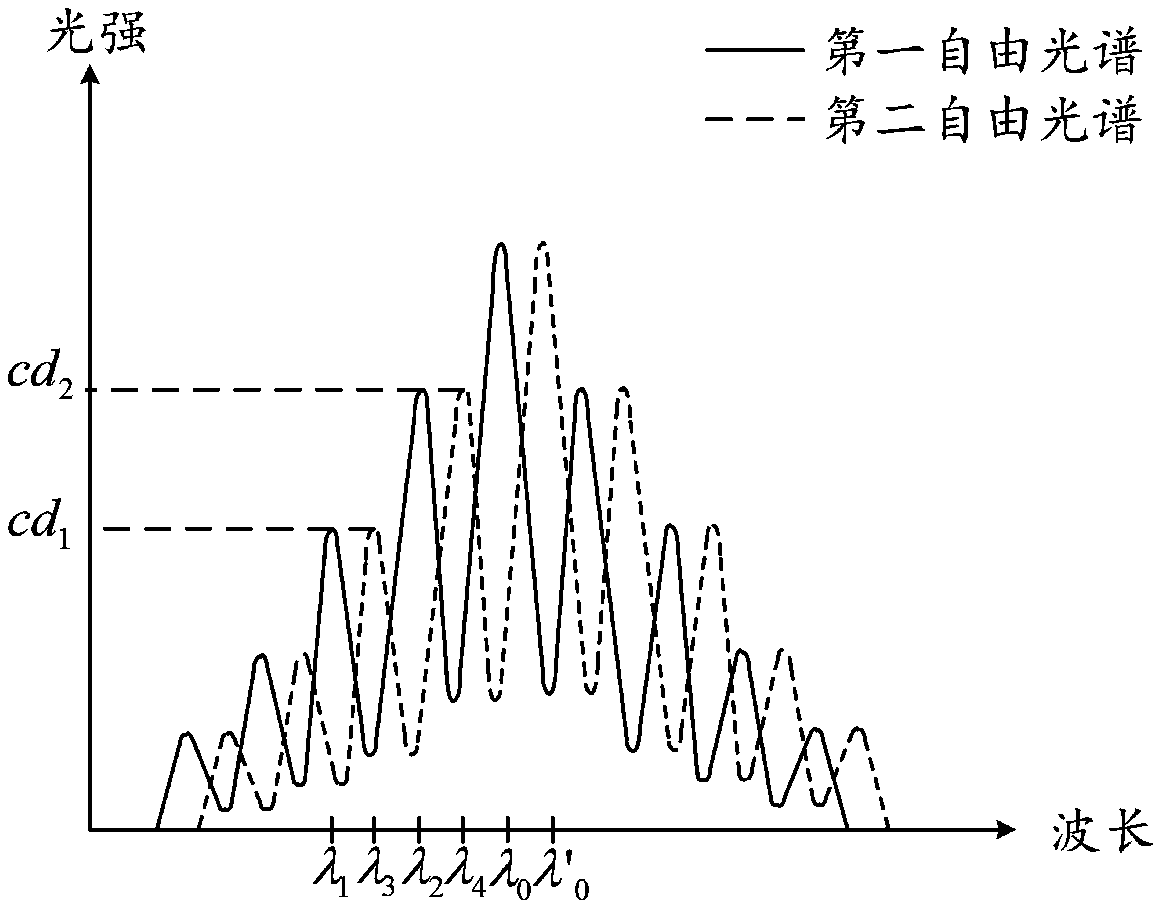

[0071] Step 130, extracting the first free spectrum light signal corresponding to each sensing component from a set of reflected light signals, and extracting the second free spectrum light signal corresponding to each sensing component from another set of reflected light signals .

[0072] Step 140: According to the optical signal in the first free spectrum region and the optical signal in the seco...

Embodiment 2

[0151] Such as Figure 7 As shown, a test system for the temperature force and additional force of a seamless line rail includes: an optical coupler, a spectrometer, a processor, and an optical fiber arranged on a seamless line rail, and the optical fiber is provided with the multiple series connected in series. a sensing assembly, each sensing assembly includes: a first resonant cavity and a second resonant cavity, the axis of symmetry of the first resonant cavity is parallel to the cavity length direction of the second resonant cavity;

[0152] The optical coupler is used to obtain two sets of reflected optical signals output by the optical fiber at different times and transmit them to the spectrometer;

[0153] The spectrometer is used to extract the first free spectral region light signal corresponding to each sensing component from a set of reflected light signals, and extract the second free spectral region light corresponding to each sensing component from another set o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Linear expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com