Ventilating vacuum fast mud-water separating method for dredging high-water content mud accumulation yard

A technology for dredging silt and separation of mud and water, which is applied in the fields of ports, waterways and water conservancy projects, can solve the problems of large amount of dredged silt, occupy a lot of land and take a long time, so as to reduce the water content of the silt, reduce the occupied area, and reduce the effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

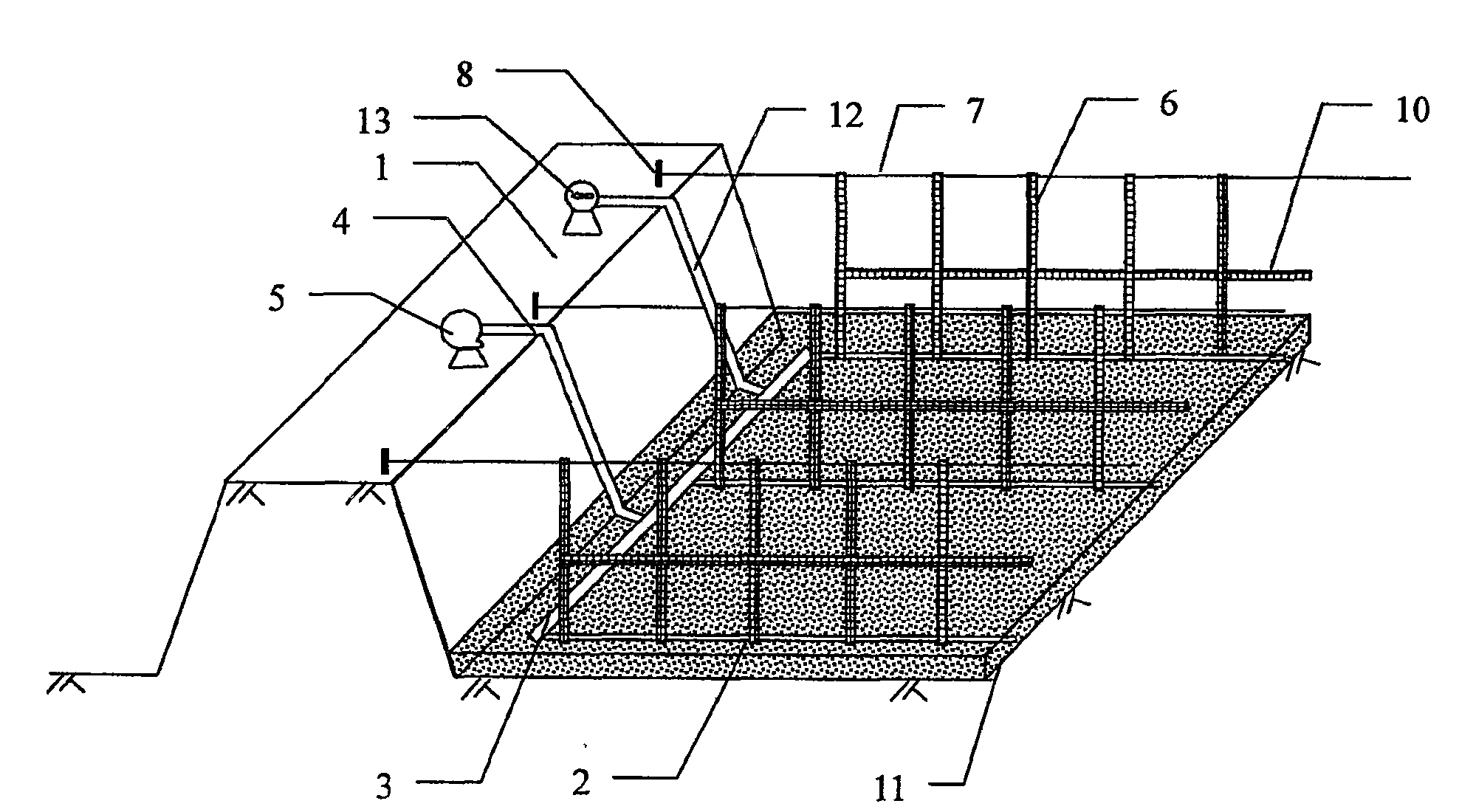

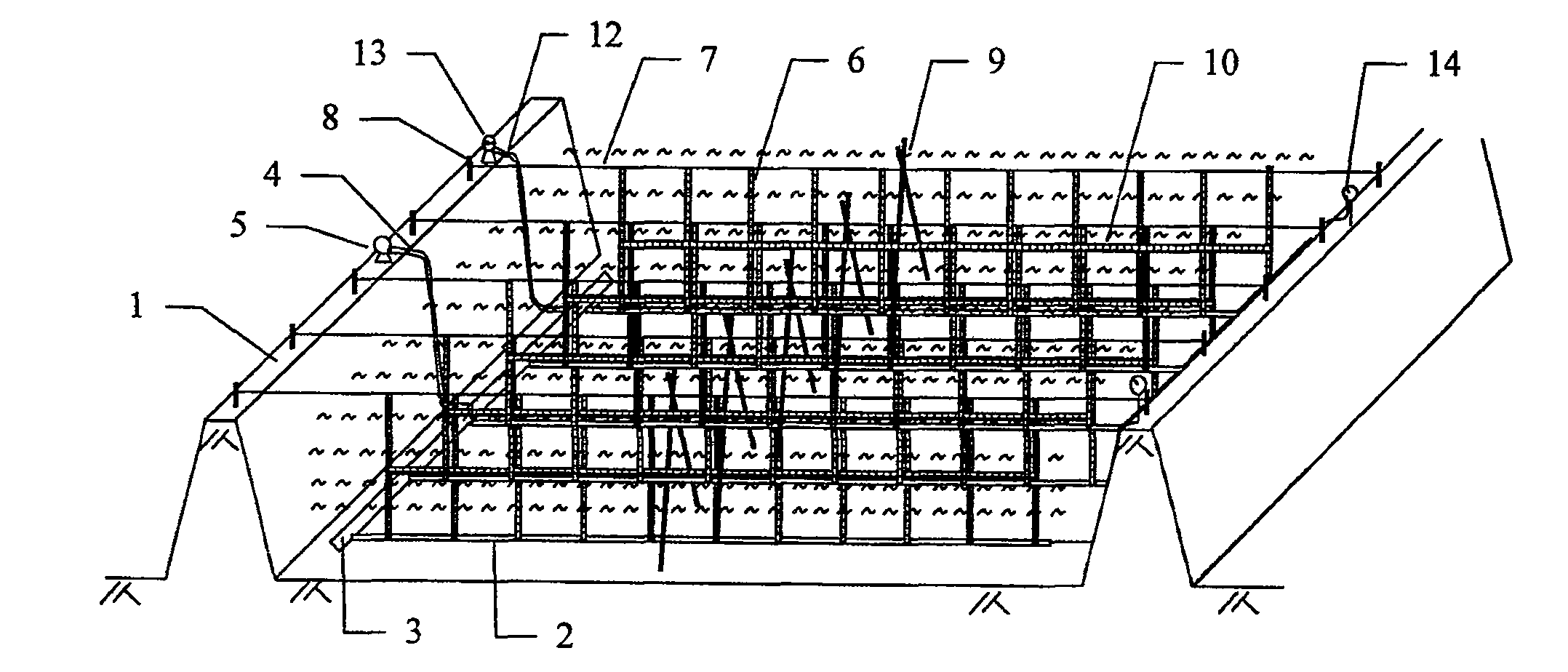

[0015] Such as figure 1 and figure 2 As shown, the specific steps and contents of the construction are as follows:

[0016] 1. Structure space drainage system:

[0017] 1) Processing materials: do a good job of drilling water filter pipes, covering water filter materials and cutting off plastic drainage boards at the material processing site;

[0018] 2) Laying of horizontal, horizontal and vertical drainage channels: Firstly, on the foundation in the cofferdam 1, a connected horizontal and horizontal water filtration and drainage pipe network 2 and a horizontal vertical drainage pipeline 3 are erected, and a vacuum device 5 and a vacuum device 5 are installed on the cofferdam 1. Ventilation device 13, horizontal and vertical drainage pipe 3 communicates with vacuum device 5 through water guide pipe 4, communicates with ventilation device 13 through air guide pipe 12, vertical plastic drainage board 6 is connected side by side on horizontal and horizontal water drainage pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com