Vacuum plume pneumatic thermal full field measurement system based on pressure sensitive/temperature sensitive paint

A measurement system and temperature-sensitive technology, applied in aerodynamic tests, fluid pressure measurement using optical methods, testing of machine/structural components, etc., can solve the problems of increased time and economic costs, discrete measurement points, damaged model surfaces, etc. problems, achieve the effects of shortening the test preparation time, increasing the data collection rate, and simplifying the subsidiary structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

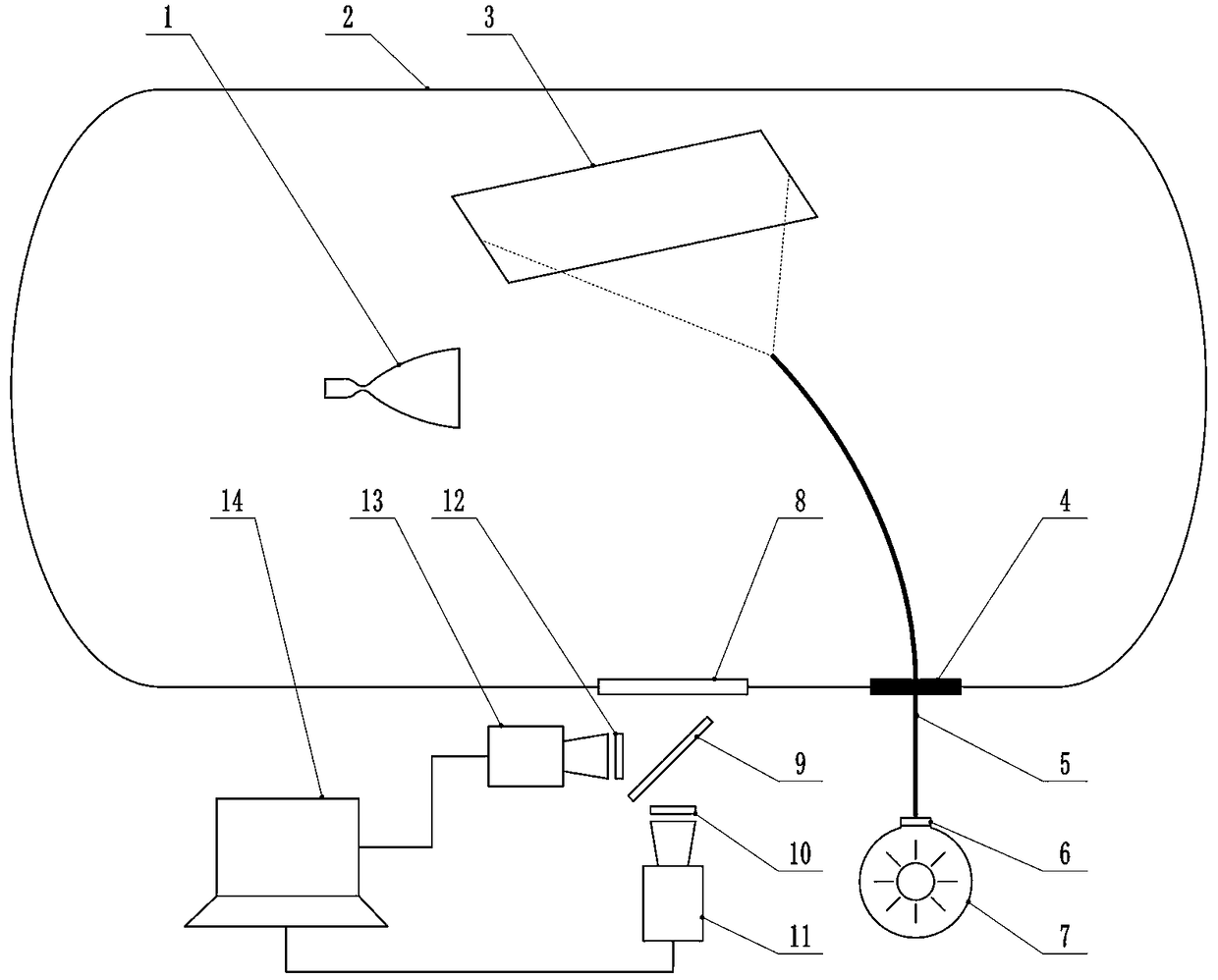

[0026] Such as figure 1 As shown, a vacuum plume aerodynamic heat full-field measurement system based on pressure-sensitive / temperature-sensitive paint is used to measure the aerodynamic force and aerodynamic heat of the aerodynamic model under the action of the vacuum plume injected by the engine. The measurement system includes a vacuum Cabin 2, aerodynamic model 3, engine 1, pressure-sensitive / temperature-sensitive paint layer, excitation light assembly, emission light channel and image acquisition and analysis module; the aerodynamic model and engine are arranged in a vacuum chamber; the pressure-sensitive / temperature-sensitive The sensitive paint layer is a paint layer that contains pressure-sensitive luminescent molecules and temperature-sensitive luminescent molecules and is sprayed on the surface of the aerodynamic model to be tested; the excitation light component includes a laser light source 7 and a low-pass filter 6 arranged sequentially in the light-emitting direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com