Test device for testing brake pad wear property and use method thereof

A wear performance and test device technology, which is applied in the direction of testing wear resistance, measuring devices, and mechanical parts testing, can solve problems affecting driving safety, long brake pad wear test cycle, and inaccurate experimental data, etc., to ensure the structure Stability, the test results are more convincing, and the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

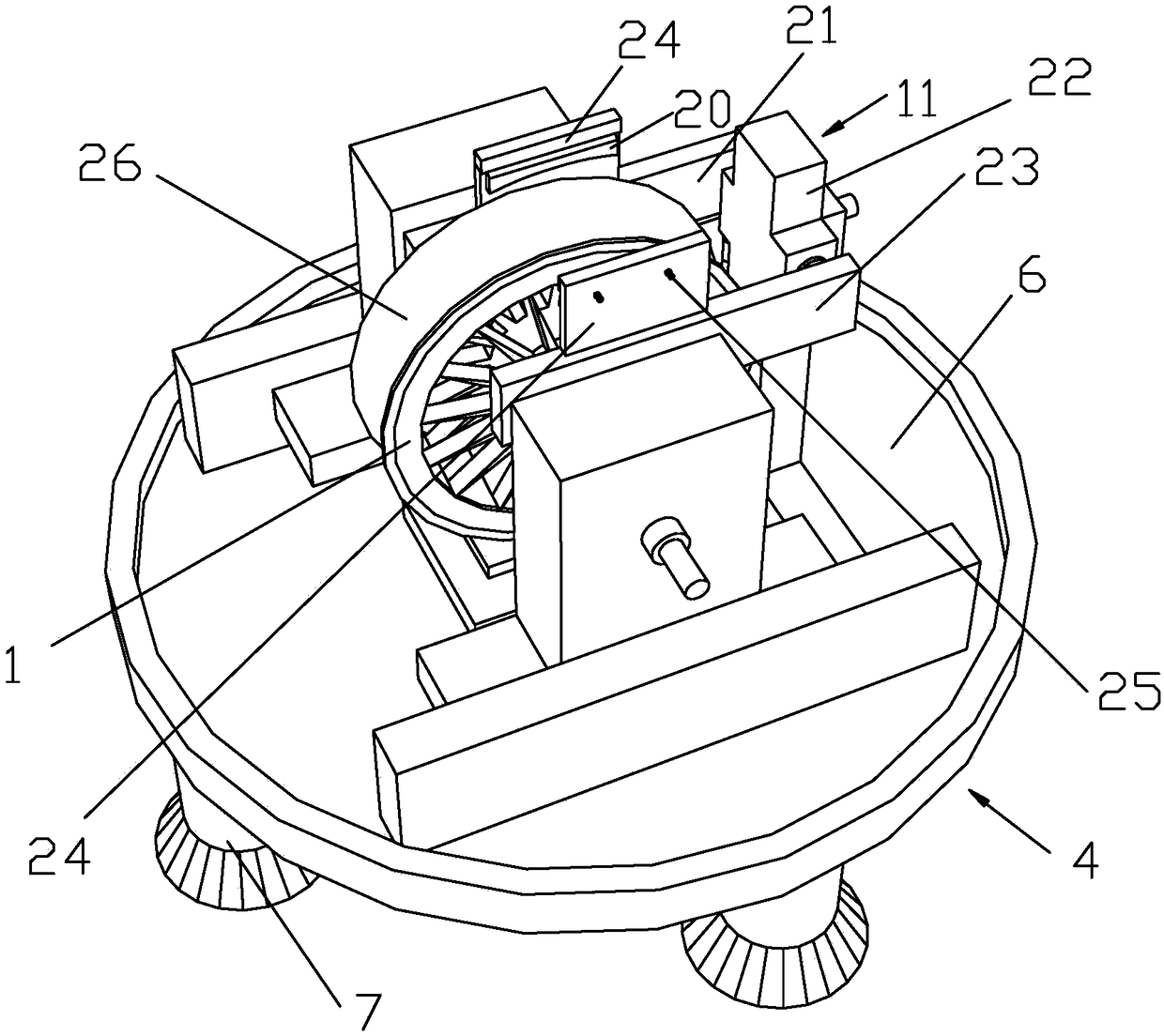

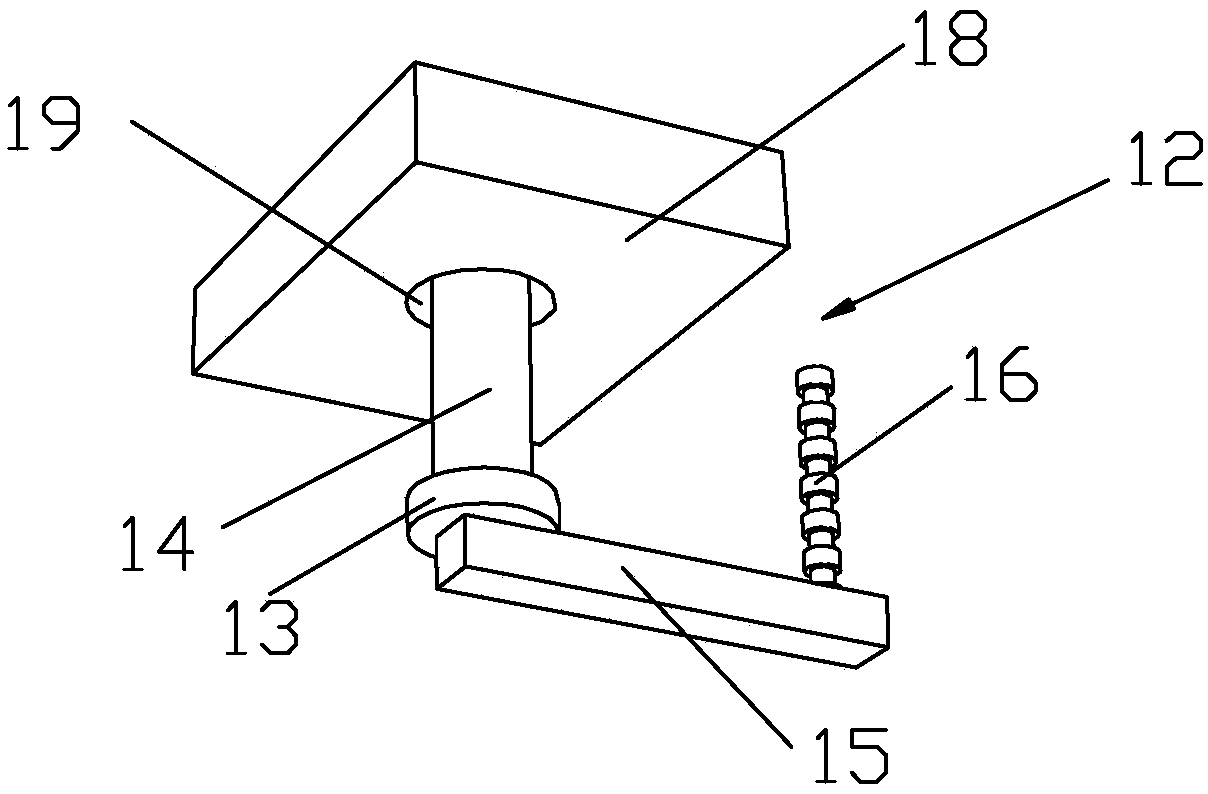

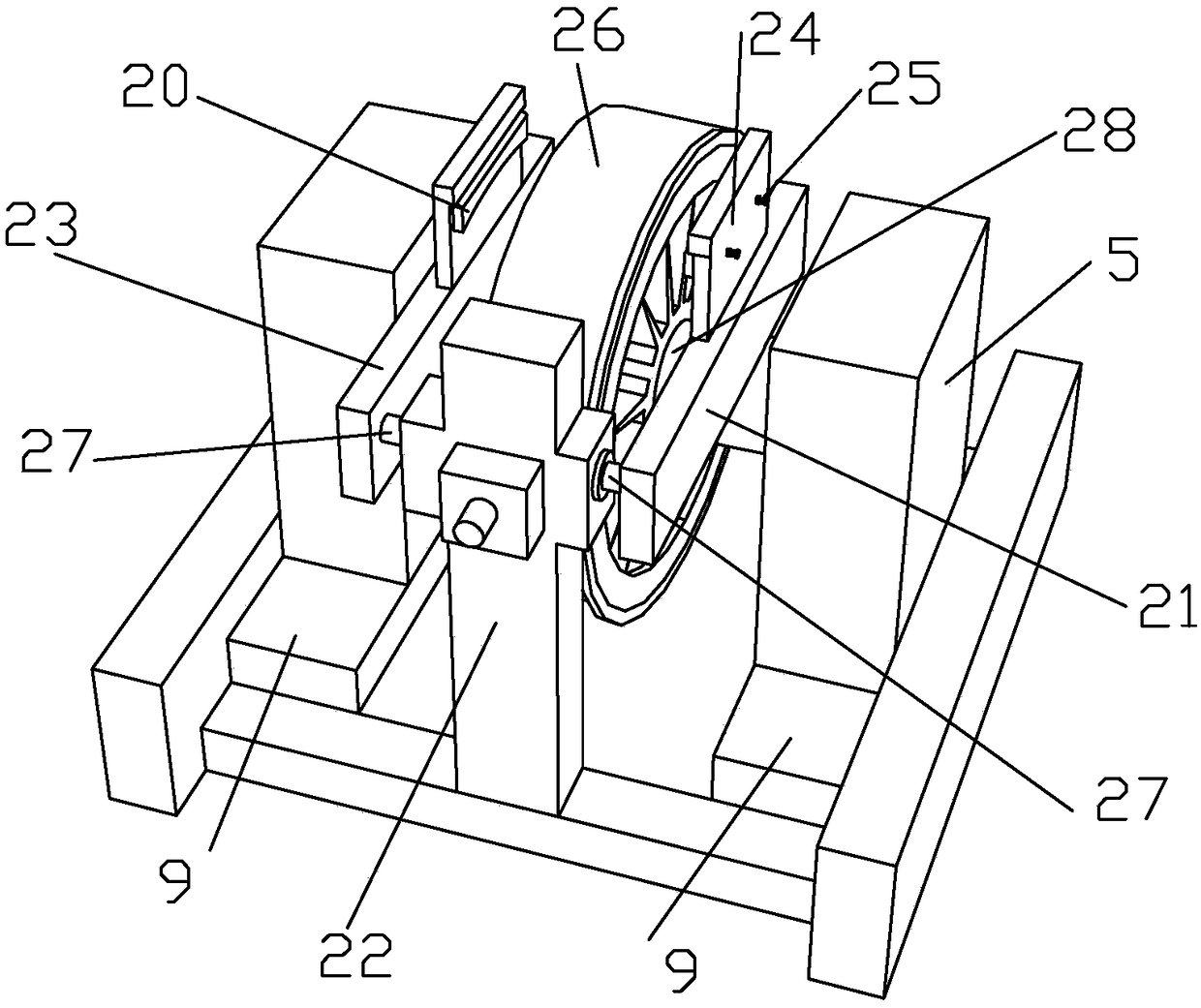

[0039] Such as Figure 1 to Figure 7 As shown, in order to solve the above technical problems, the present invention adopts the following technical solutions:

[0040] A test device for testing the wear performance of brake pads, including a hub 1, a brake test bench 2 and a control system, and an operating platform 3, the operating platform 3 includes a support system 4 and a functional system, and the support system 4 includes a chassis 6 and a bottom Foot 7, the foot 7 is arranged below the chassis 6, the functional system includes a simulated ground component 8 and a lifting device, the simulated ground component 8 comprises a simulated ground panel 10, a fixing part and an adjusting part 12, and the adjusting part 12 includes a limit ring 13, Connecting rod 14, guide plate 15 and threaded rod 16, the top of connecting rod 14 is installed below the simulated ground panel 10, connecting rod 14 passes through fixing part respectively, and connecting rod 14 is provided with l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com