Asphalt regenerant consumption determining method based on rheological performance balance design

A technology of asphalt regeneration agent and rheological properties, applied in the direction of material inspection products, etc., can solve the problems of consumables and time-consuming, and achieve the effect of fast and accurate dosage determination, less asphalt dosage, and reduced stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

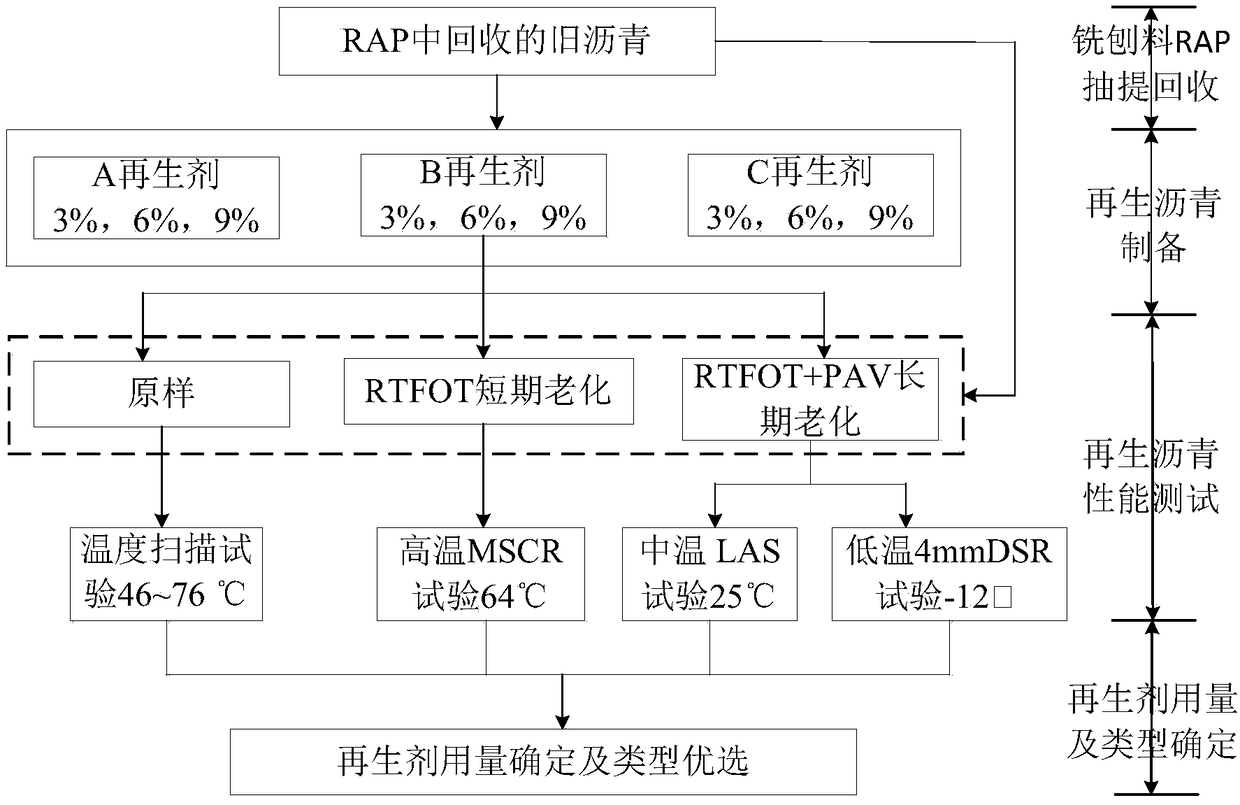

[0043] The method for determining the amount of regenerant based on rheological performance balance design in this embodiment and the verification steps for road performance of the mixture are as follows:

[0044] (1) Select A regenerant to blend with the old asphalt in RAP according to the dosage of 3%, 6%, and 9%, respectively, stir evenly at 130°C for 30 minutes, and keep it at this temperature for 2 hours, so that the regenerant and aging The asphalt is fully fused to prepare recycled asphalt;

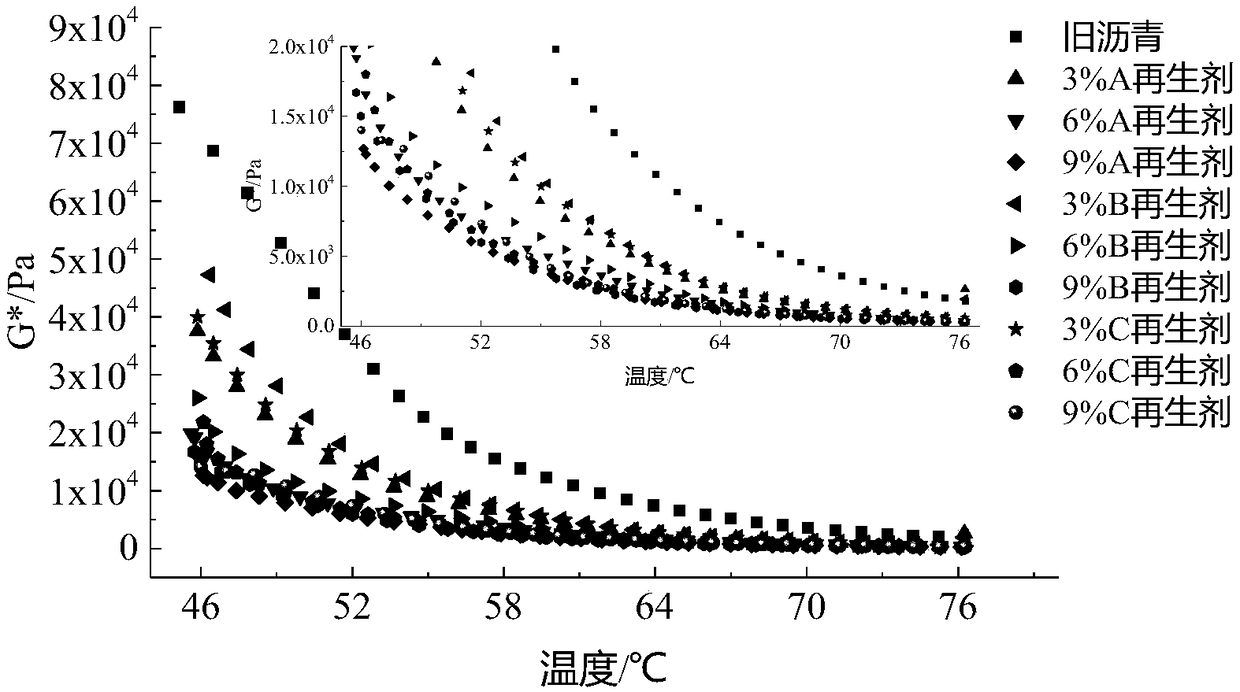

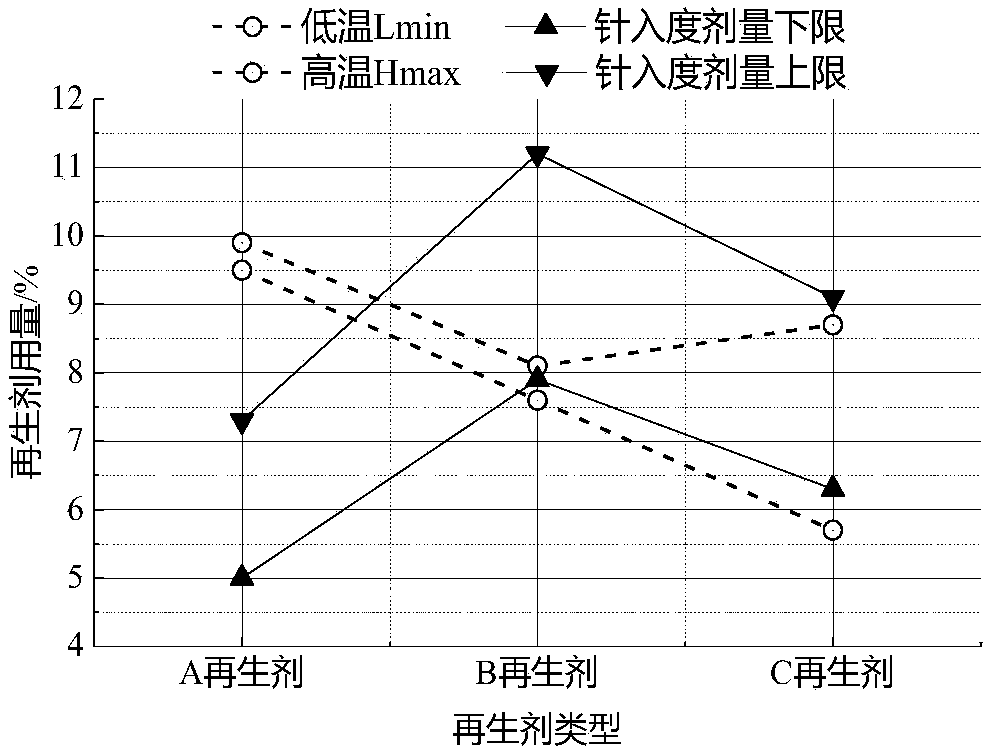

[0045] (2) Carry out temperature scanning, MSCR, LAS and 4mm-DSR low-temperature frequency scanning tests on recycled asphalt, and test the composite shear modulus G of recycled asphalt samples * , high temperature non-recoverable creep compliance J nr-3.2 、Medium temperature fatigue failure life N f , low temperature relaxation modulus G r(60s) and relaxation rate |m r (60s)|Indicators, the results are shown in Table 3;

[0046] Table 3 Test results of A regenerant asphalt te...

Embodiment 2

[0051] The method for determining the amount of regenerant based on rheological performance balance design in this embodiment and the verification steps for road performance of the mixture are as follows:

[0052] (1) Select B regenerant to blend with the old asphalt in RAP according to the dosage of 3%, 6% and 9%, respectively, stir evenly at 130°C for 30min, and keep warm at this temperature for 2h, so that the regenerant and aging The asphalt is fully fused to prepare recycled asphalt;

[0053] (2) Carry out temperature scanning, MSCR, LAS and 4mm-DSR low-temperature frequency scanning tests on recycled asphalt, and test the composite shear modulus G of recycled asphalt samples * , high temperature non-recoverable creep compliance J nr-3.2 、Medium temperature fatigue failure life N f , low temperature relaxation modulus G r (60s) and relaxation rate |m r (60s)|Indicators, the results are shown in Table 4;

[0054] Table 4 Test results of B regenerant asphalt technical ...

Embodiment 3

[0059] The method for determining the amount of regenerant based on rheological performance balance design in this embodiment and the verification steps for road performance of the mixture are as follows:

[0060] (1) Select C regenerant to blend with the old asphalt in RAP according to the doses of 3%, 6%, and 9%, respectively, stir evenly at 130°C for 30 minutes, and keep warm at this temperature for 2 hours to make the regenerant and aging The asphalt is fully fused to prepare recycled asphalt;

[0061] (2) Carry out temperature scanning, MSCR, LAS and 4mm-DSR low-temperature frequency scanning tests on recycled asphalt, and test the composite shear modulus G of recycled asphalt samples * , high temperature non-recoverable creep compliance J nr-3.2 、Medium temperature fatigue failure life N f , low temperature relaxation modulus G r (60s) and relaxation rate |m r (60s)|Indicators, the results are shown in Table 5;

[0062] Table 5 Test results of C regenerant asphalt t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com