A method based on immune genetic algorithm for solving the assembly line balance problem of the first kind

An immune genetic algorithm and assembly line technology, which is applied in the field of solving the first type of assembly line balance problem based on immune genetic algorithm, which can solve problems such as small computing scale and reduced practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

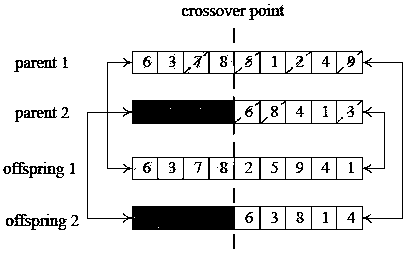

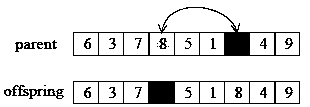

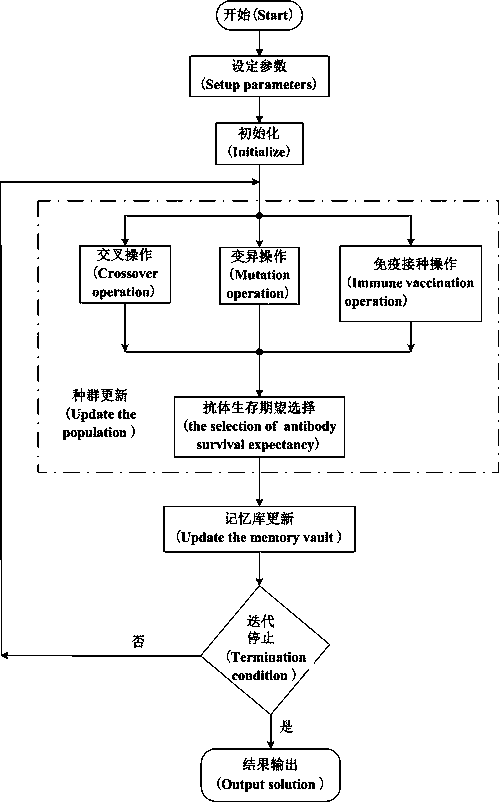

[0088] Below in conjunction with accompanying drawing, the present invention will be further described.

[0089] A method based on immune genetic algorithm to solve the first type of assembly line balance problem, such as Figure 1-Figure 3 As shown, the method includes the following steps:

[0090] 1) Definition of function ψ(∙):

[0091] A *, Satisfy:

[0092] (1) if then exchange matrix A middle with s position;

[0093] (2) if then the matrix A middle with The position remains the same;

[0094] in,

[0095]

[0096]

[0097]

[0098] n represents the total number of assembly tasks; matrix A Any column in represents n a full permutation of

[0099]

[0100] 2) Constraints include:

[0101] An assembly job element can only be assigned to one workstation

[0102]

[0103] in, k Indicates the serial number of the assembly station, M represents the total number of assembly stations, i Indicates the serial number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com