A braided coated cable and a manufacturing method thereof

A cable and coating technology, which is applied in the field of braided and coated cables and its manufacturing, can solve the problems of silicone rubber materials such as non-wear resistance, safety hazards, and easy tearing, so as to improve temperature resistance, improve bending performance, and meet resistance pull effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

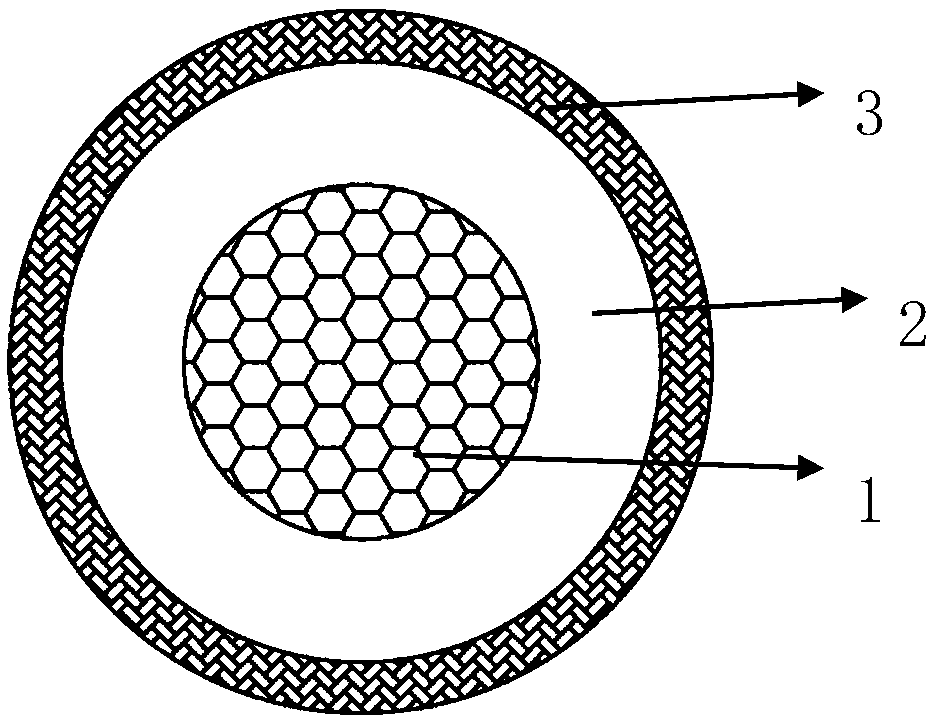

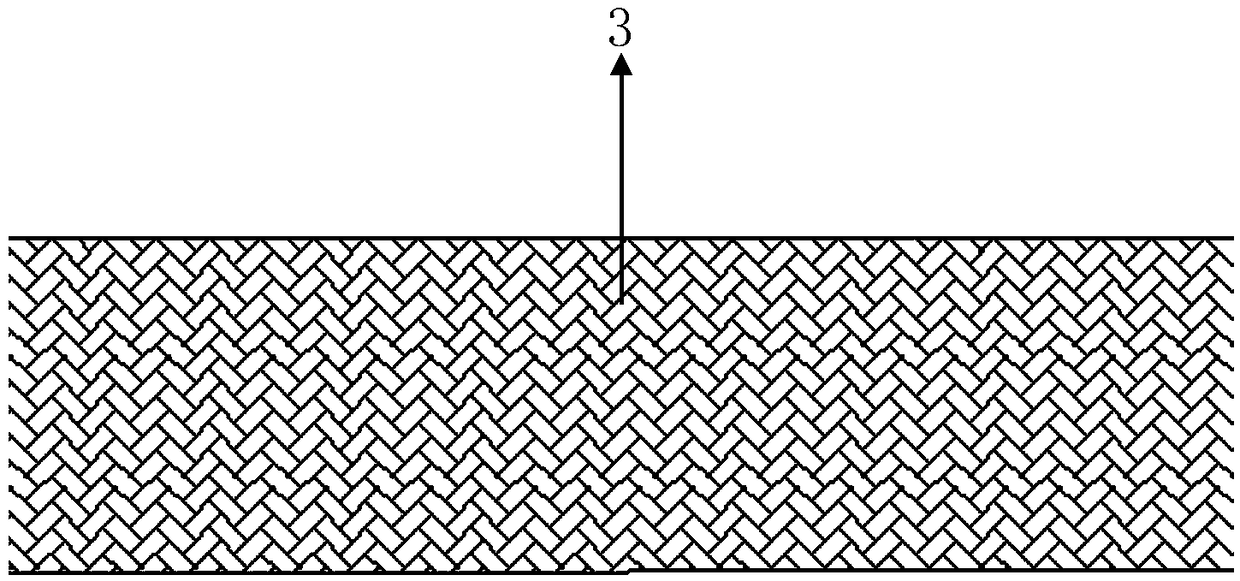

[0017] Such as figure 1 As shown, the braided coated cable of the present invention is used in new energy vehicles, which includes a central conductor 1 , an insulating layer 2 outside the conductor 1 , and a braided coating layer 3 outside the insulating layer 2 . Among them, the central conductor 1 is a stranded annealed bare copper conductor or a stranded annealed tinned copper conductor, the insulating layer 2 is coated on the outer ring surface of the central conductor 1, and the braided coating layer 3 is tightly wrapped on the outer ring of the insulating layer 2 .

[0018] Center conductor 1 conforms to the Class 6 annealed bare copper conductor required by GB / T3956.

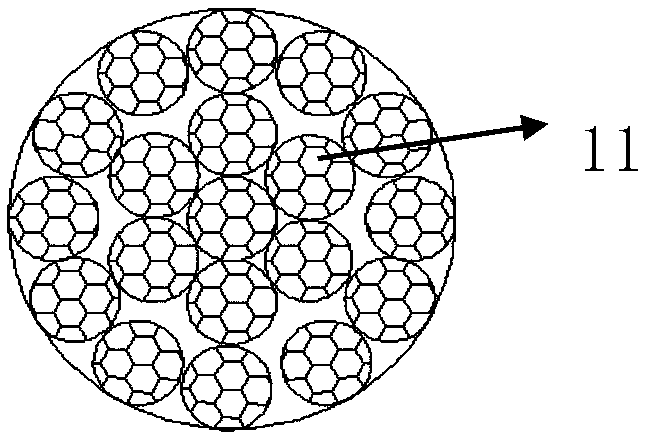

[0019] Such as figure 2 As shown, the central conductor 1 includes a plurality of single-strand wires 11, and the central conductor 1 is formed by a plurality of single-strand wires 11, that is, the central conductor 1 adopts a cross regular twisted structure of ultra-fine copper wire multi-element sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com