A preparation method of a display substrate, a display substrate and a display screen

A technology for display substrates and display screens, which is applied in the photoengraving process of the pattern surface, opto-mechanical equipment, semiconductor/solid-state device manufacturing, etc. Effectiveness of utilization rate and reduction of production and development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

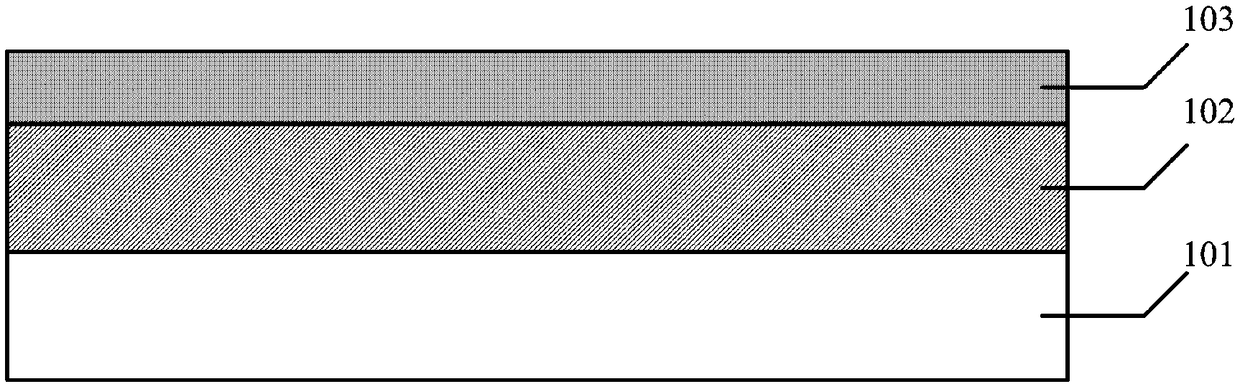

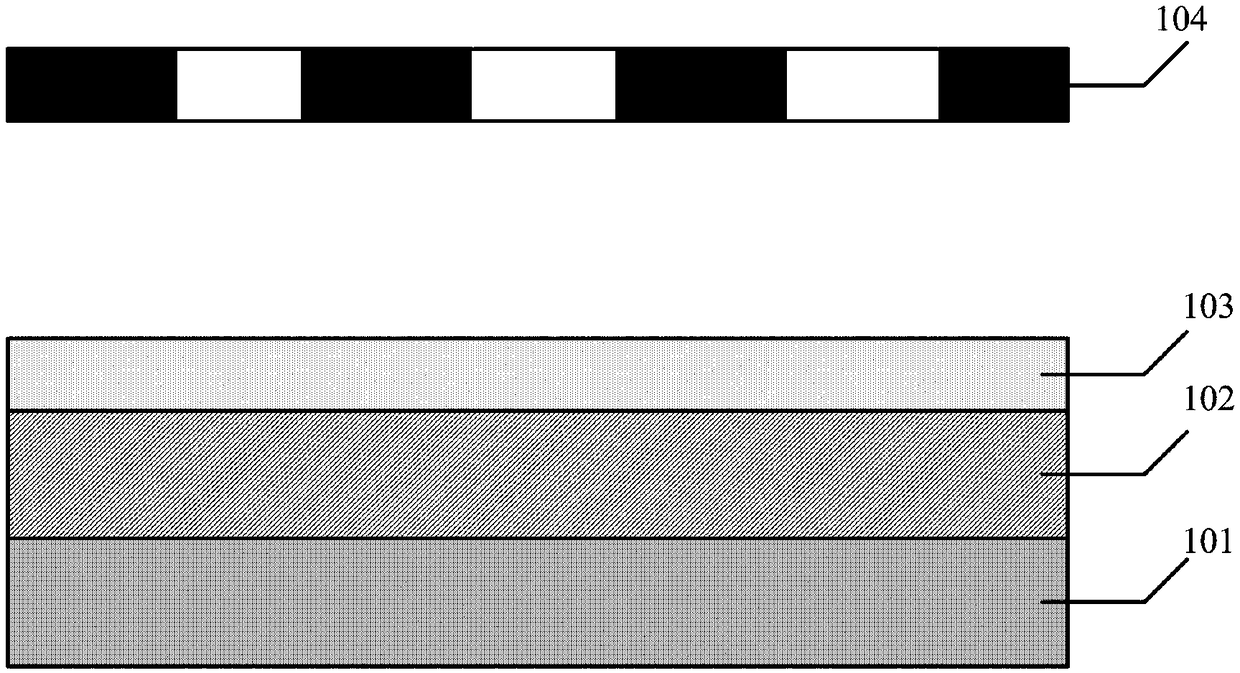

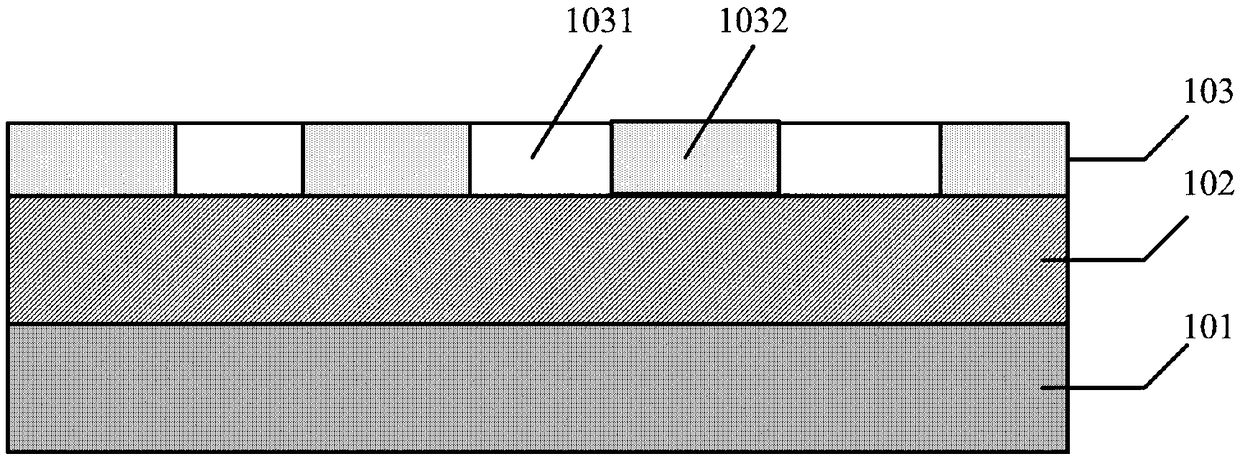

[0059] Such as Figure 5 As shown in FIG. 2 , it is a flow chart for realizing a method for manufacturing a display substrate provided by an embodiment of the present invention. The method comprises the steps of:

[0060] Step 50 , coating a metal material on the substrate on which the black matrix region is formed by using the first mask.

[0061] Wherein, the base substrate may be a glass substrate, a plastic substrate, or the like.

[0062] The first mask here refers to the above-mentioned BM Mask.

[0063] Step 51, coating photoresist on the metal material.

[0064] Optionally, the photoresist is a positive photoresist.

[0065] Step 52, using the second mask to perform the first exposure treatment on the photoresist.

[0066] The second mask here refers to the Metal Mask mentioned above.

[0067] Step 53, using the first mask plate to perform a second exposure treatment on the photoresist.

[0068] Step 54 , developing the photoresist after two exposures to expose pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com