A kind of preparation method of graphene-nano carbon fiber conductive agent

A technology of carbon nanofibers and a manufacturing method, which is applied in the field of electrochemical materials, can solve the problems of poor conductivity of lithium ion batteries, etc., and achieve the effects of good compatibility, improved conductivity, and reduced addition amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

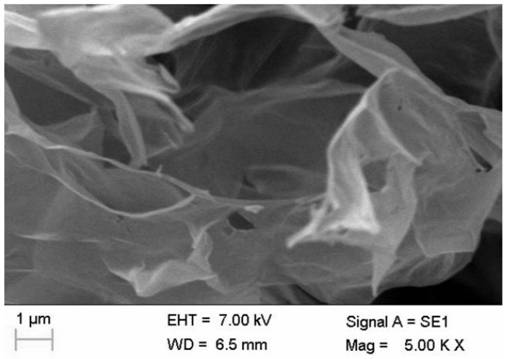

Image

Examples

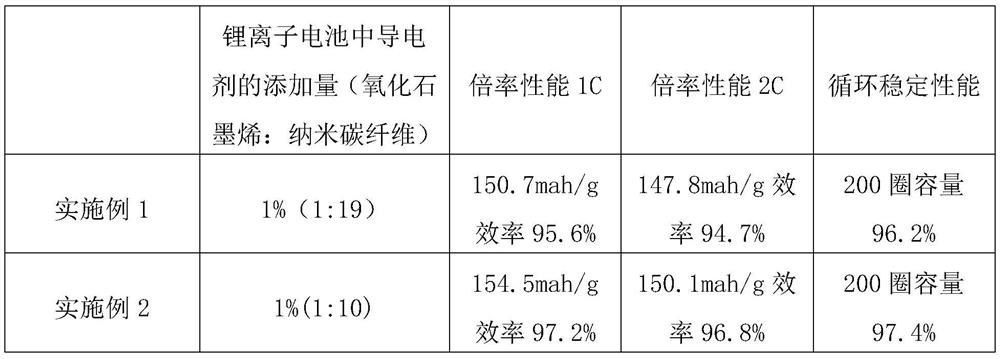

Embodiment 1

[0020] A kind of preparation method of graphene-nano carbon fiber conductive agent, comprises the following steps:

[0021] 1) Oxidize the graphite into graphite oxide with an oxidant, and then ultrasonically peel the graphite oxide into graphene oxide;

[0022] Among them, the oxidizing agent is concentrated sulfuric acid, fuming nitric acid, potassium permanganate and hydrogen peroxide. The preparation process of graphite oxide is: stirring and dispersing graphite in concentrated sulfuric acid, adding fuming nitric acid after stirring for 20 minutes, controlling the temperature of the water bath to 20°C, and then slowly Add potassium permanganate, the rate of adding potassium permanganate is 3g / min, keep the reaction temperature at 25°C during the addition of potassium permanganate, continue stirring for 148h, add water, add hydrogen peroxide after heating to 92°C, and stir for 0.5h , and then wash with a ceramic membrane, adjust the pH to 7 after washing with water, and obt...

Embodiment 2

[0029] A kind of preparation method of graphene-nano carbon fiber conductive agent, comprises the following steps:

[0030] 1) Oxidize the graphite into graphite oxide with an oxidant, and then ultrasonically peel the graphite oxide into graphene oxide;

[0031] Among them, the oxidizing agent is concentrated sulfuric acid, fuming nitric acid, potassium permanganate and hydrogen peroxide. The preparation process of graphite oxide is: stirring and dispersing graphite in concentrated sulfuric acid, adding fuming nitric acid after stirring for 25 minutes, controlling the temperature of the water bath to 23 °C, and then slowly Add potassium permanganate, continue stirring for 149 hours, then add water, heat up to 93°C, add hydrogen peroxide, stir for 0.8 hours, then wash with a ceramic membrane, adjust the pH to 6.8 after washing with water, and obtain graphite oxide.

[0032] 2) Add 600 g of treated nano-carbon fibers to 10 g of graphene oxide, then add 10 g of phosphorus pentach...

Embodiment 3

[0037] A kind of preparation method of graphene-nano carbon fiber conductive agent, comprises the following steps:

[0038] 1) Oxidize the graphite into graphite oxide with an oxidant, and then ultrasonically peel the graphite oxide into graphene oxide;

[0039] Among them, the oxidizing agent is concentrated sulfuric acid, fuming nitric acid, potassium permanganate and hydrogen peroxide. The preparation process of graphite oxide is as follows: graphite is stirred and dispersed in concentrated sulfuric acid, and after stirring for 30 minutes, fuming nitric acid is added, and the temperature of the water bath is controlled at 25°C, and then slowly Add potassium permanganate, continue stirring for 150 hours, then add water, heat up to 95°C, add hydrogen peroxide, stir for 150 hours, then wash with a ceramic membrane, adjust the pH to 7.3 after washing with water, and obtain graphite oxide.

[0040] 2) Add 600 g of treated nano-carbon fibers to 20 g of graphene oxide, then add 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com