A hybrid material resistant to atomic oxygen erosion in space environment and its preparation method

A hybrid material and space environment technology, applied in the direction of silicon oxide, silicon dioxide, etc., can solve the problems of loss of protective effect of coating, damage to spacecraft, and difficulty, and ensure dispersion and bonding, uniform dispersion, and easy control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

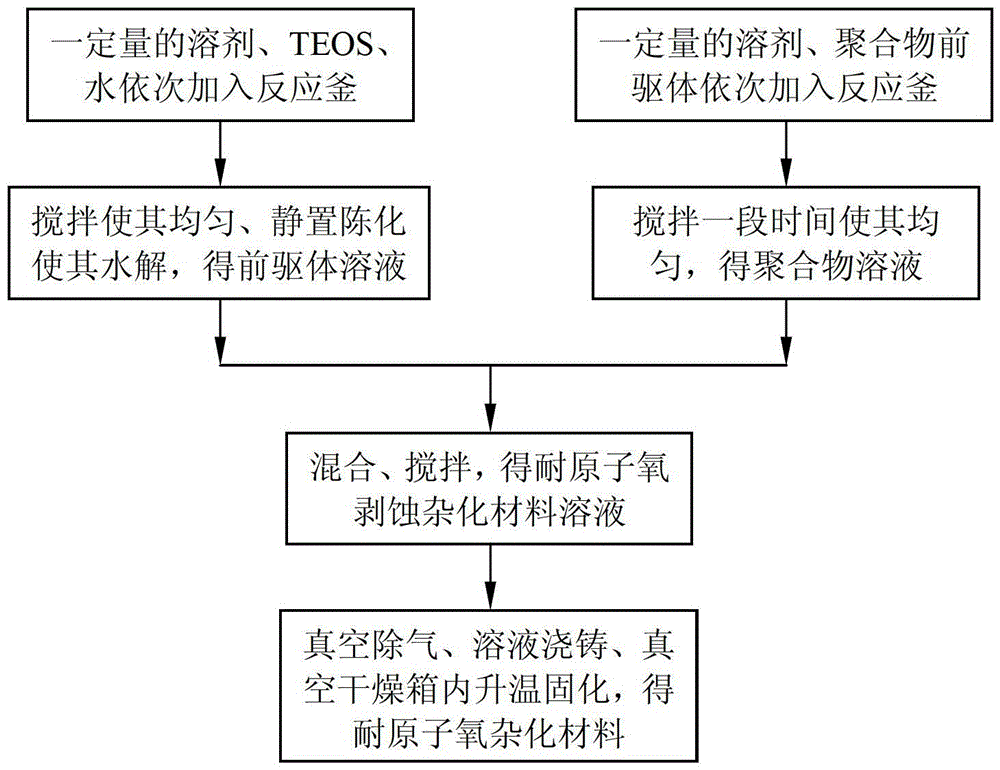

[0093] see figure 1 , Polyimide resin (PMDA / ODA system) dosage ODA50 parts (by weight), PMDA55 parts, TEOS dosage 40 parts to prepare organic / inorganic hybrid materials resistant to atomic oxygen ablation.

[0094] The preparation method is as follows:

[0095] (A) Weigh polymer precursors ODA, PMDA and sol-gel precursor TEOS

[0096] Weigh according to ODA:PMDA:TEOS mass ratio=50:55:20 or 50:55:40 or 50:55:75 or 50:55:150;

[0097] (B) Prepare polyamic acid (PAA) solution

[0098] 50 parts of ODA, 500 parts of solvent DMAC, dissolve ODA into DMAC, stir and mix evenly to obtain ODA / DMAC solution;

[0099] Under stirring, add 55 parts of PMDA to the ODA / DMAC solution in 5 times, stirring for about 10 minutes each time to make it dissolve as completely as possible. After dissolution, the solution becomes a golden yellow viscous liquid. Continue stirring for 2 hours to make the solution Complete reaction (aging process) to obtain polyamic acid solution.

[0100] (C) Preparation of sol-gel p...

Embodiment 2

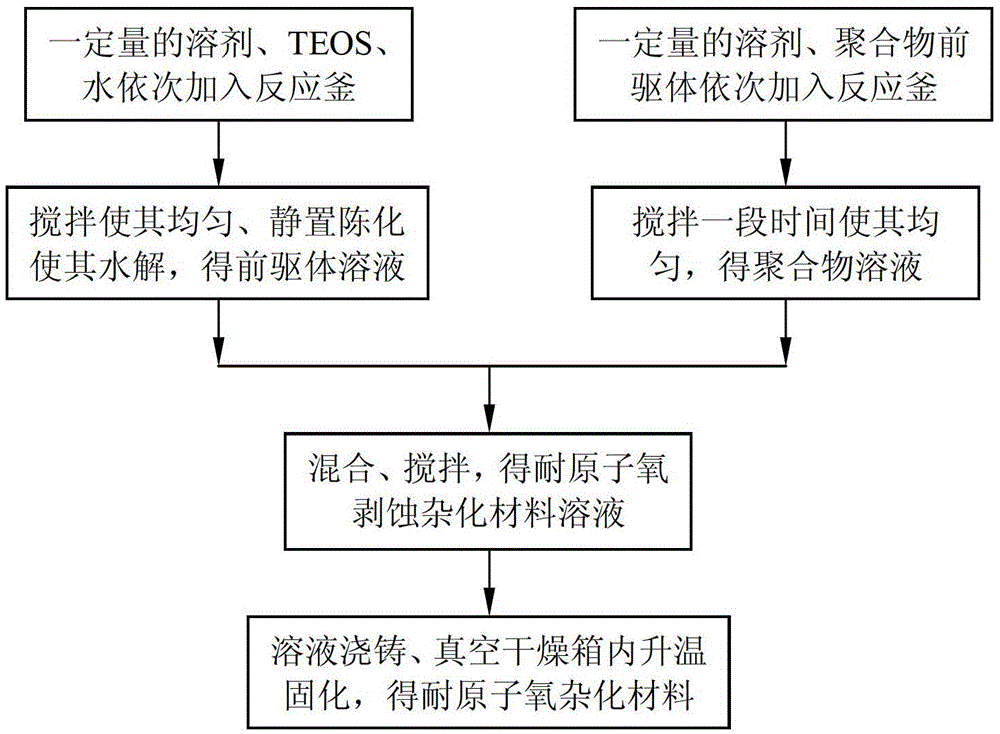

[0114] see figure 2 , Polyimide resin (PMDA / ODA system) dosage ODA50 parts (by weight), PMDA55 parts, TEOS dosage 40 parts to prepare organic / inorganic hybrid materials resistant to atomic oxygen ablation.

[0115] The preparation method is as follows:

[0116] (A) Weigh polymer precursors ODA, PMDA and sol-gel precursor TEOS

[0117] According to ODA:PMDA:TEOS mass ratio=50:55:40;

[0118] (B) Prepare polyamic acid (PAA) solution

[0119] 50 parts of ODA, 500 parts of solvent DMAC, dissolve ODA into DMAC, stir and mix evenly to obtain ODA / DMAC solution;

[0120] Under stirring, add 55 parts of PMDA to the ODA / DMAC solution in 5 times, stirring for about 10 minutes each time to make it dissolve as completely as possible. After dissolution, the solution becomes a golden yellow viscous liquid. Continue stirring for 2 hours to make the solution Complete reaction (aging process) to obtain polyamic acid solution.

[0121] (C) Preparation of sol-gel precursor solution

[0122] 40 parts of TEOS...

Embodiment 3

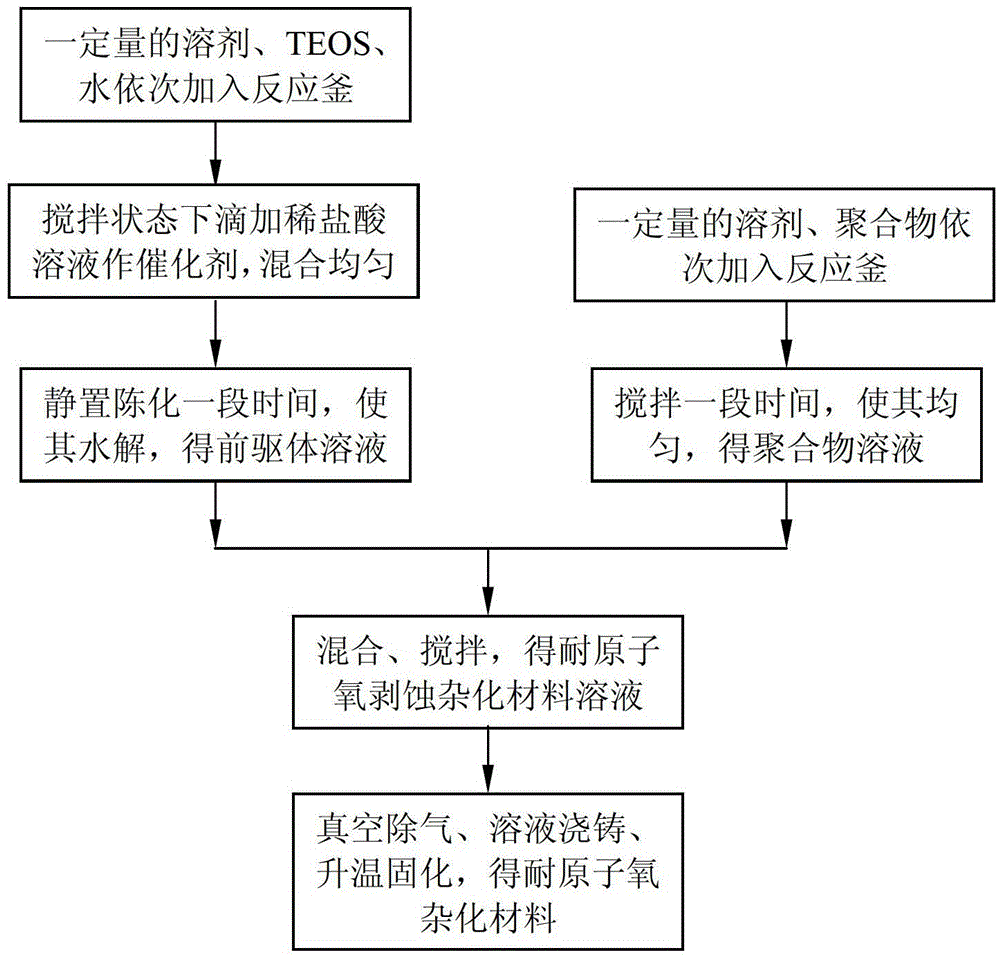

[0131] see image 3 , 100 parts of epoxy resin E51 (by weight) and 20 parts of TEOS are used to prepare organic / inorganic hybrid materials resistant to atomic oxygen ablation.

[0132] The preparation method is as follows:

[0133] (A) Weigh the polymer resin matrix and the sol-gel precursor TEOS

[0134] Weigh according to the mass ratio of polymer:sol-gel precursor=100:20;

[0135] (B) Preparation of sol-gel precursor solution

[0136] Put 20 parts of TEOS, 20 parts of water, 25 parts of ethanol or acetone into the reaction kettle and stir with a high-speed mixer (about 500 rpm) to make the system evenly mixed; during the stirring process, add dropwise dilute with a mass fraction of about 3.7% 0.2g hydrochloric acid solution is used as a catalyst to prepare a sol-gel precursor solution;

[0137] (C) Prepare polymer solution

[0138] Put 100 parts of epoxy resin E51, 50 parts of diluent acetone, and 65160 parts of curing agent polyamide PA into the reaction kettle, stir with a high-spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com