A method for forming a long-life flexible packaging battery

A soft-packed battery and chemical formation method technology, which is applied in secondary batteries, electrochemical generators, non-aqueous electrolyte batteries, etc. The effect of small air volume and long life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

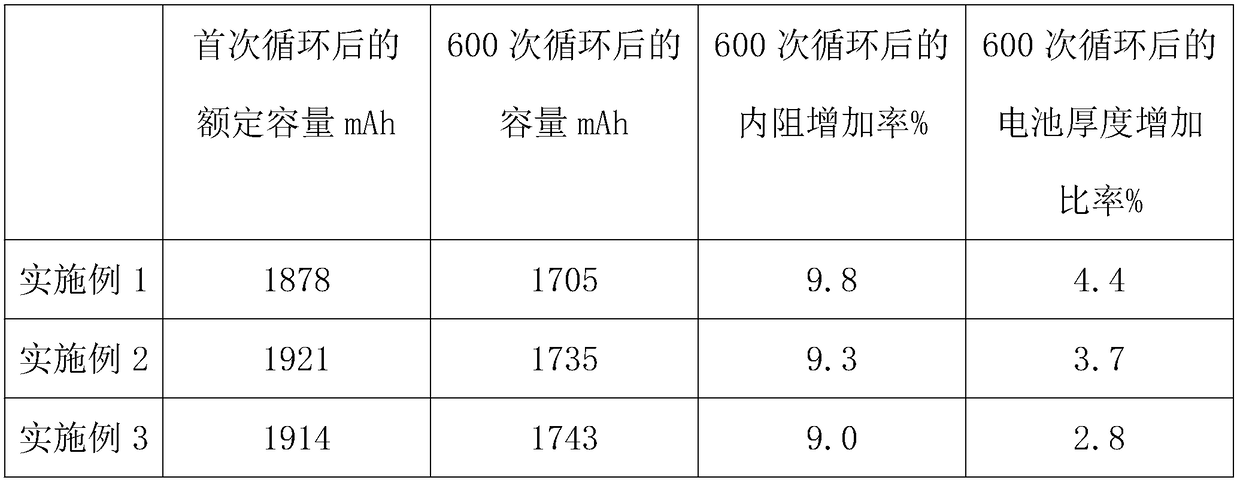

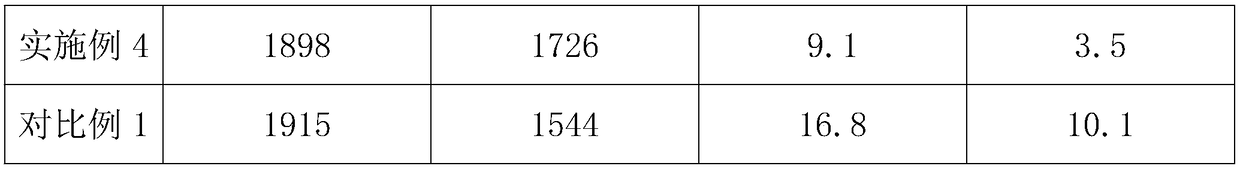

Examples

Embodiment 1

[0035] 1) Place the liquid-injected soft-packaged battery between the splints, place the battery in a glove box, vacuumize, inject protective gas, seal the battery and take it out;

[0036] 2) Charge the battery with a constant current of 0.04C at room temperature to 3.0V;

[0037] 3) Heat the battery to 45°C and charge it at a constant voltage of 3.0V until the current drops below 0.01C;

[0038] 4) Perform constant current charging and discharging cycles between 3.0V and 2.8V at room temperature for 3 times, and the charging and discharging current is 1.5 times the current in step 2;

[0039] 5), put the battery into the glove box, cut the mouth, evacuate and exhaust, pass in protective gas, seal the battery and take it out;

[0040] 6) At room temperature, pulse charge the battery to 3.5V with a pulse current, the magnitude of the pulse current is 0.5C, the pulse action time is 600s, and the interval is 30s;

[0041] 7) Heat the battery to 40°C, pulse charge the battery t...

Embodiment 2

[0050] 1) Place the liquid-injected soft-packaged battery between the splints, place the battery in a glove box, vacuumize, inject protective gas, seal the battery and take it out;

[0051] 2) Charge the battery with a constant current of 0.02C at room temperature to 2.9V;

[0052] 3) Heat the battery to 40°C and charge it at a constant voltage of 2.9V until the current drops below 0.01C;

[0053] 4) Perform constant current charging and discharging cycles between 2.9V and 2.7V at room temperature for 3 times, and the charging and discharging current is 1.5 times the current in step 2;

[0054] 5), put the battery into the glove box, cut the mouth, evacuate and exhaust, pass in protective gas, seal the battery and take it out;

[0055] 6) At room temperature, pulse charge the battery to 3.4V with a pulse current, the magnitude of the pulse current is 0.1C, the pulse action time is 100s, and the interval is 10s;

[0056] 7) Heat the battery to 35°C, pulse charge the battery to ...

Embodiment 3

[0065] 1) Place the liquid-injected soft-packaged battery between the splints, place the battery in a glove box, vacuumize, inject protective gas, seal the battery and take it out;

[0066] 2) Charge the battery with a constant current of 0.03C at room temperature to 2.9V;

[0067] 3) Heat the battery to 45°C and charge it at a constant voltage of 2.9V until the current drops below 0.01C;

[0068] 4) Perform constant current charge and discharge cycles between 2.9V and 2.7V for 5 times at room temperature, and the charge and discharge current is 1.5 times the current in step 2;

[0069] 5), put the battery into the glove box, cut the mouth, evacuate and exhaust, pass in protective gas, seal the battery and take it out;

[0070] 6) At room temperature, pulse charge the battery to 3.5V with a pulse current, the magnitude of the pulse current is 0.3C, the pulse action time is 200s, and the interval is 20s;

[0071] 7) Heat the battery to 40°C, pulse charge the battery to 3.8V w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com