Surface treatment method of metal products and metal products

A metal product and surface treatment technology, which is applied in the surface treatment of metal products and the field of metal products, can solve problems such as differences in nanocrystalline structure, achieve high surface strengthening effects, prevent built-up edge, and prevent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0098] (confirmation of optimal conditions)

[0099] (1) Particle size of sprayed particles

[0100] (1-1) Idea point

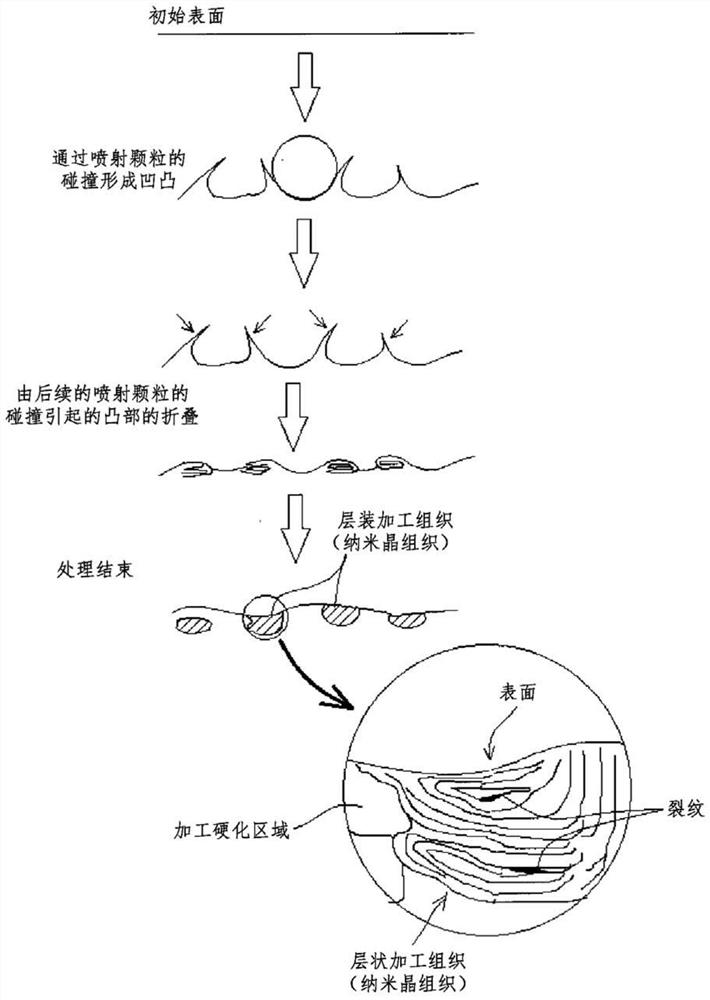

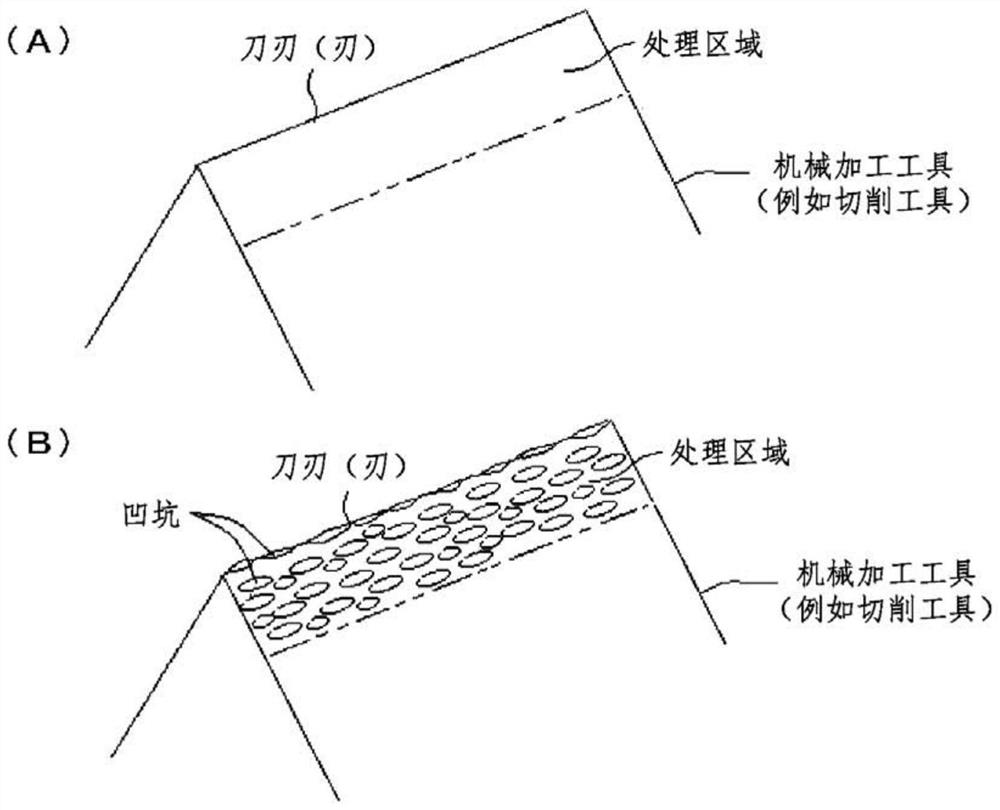

[0101] As mentioned above, in order to continuously form a uniform layer of nanocrystalline structure along the surface of metal products made of soft materials, it is necessary to suppress the generation of reference figure 1 In order to suppress the formation of the layered processed structure described above, it is necessary to suppress the deformation of the surface of the metal product that occurs when the sprayed powder collides.

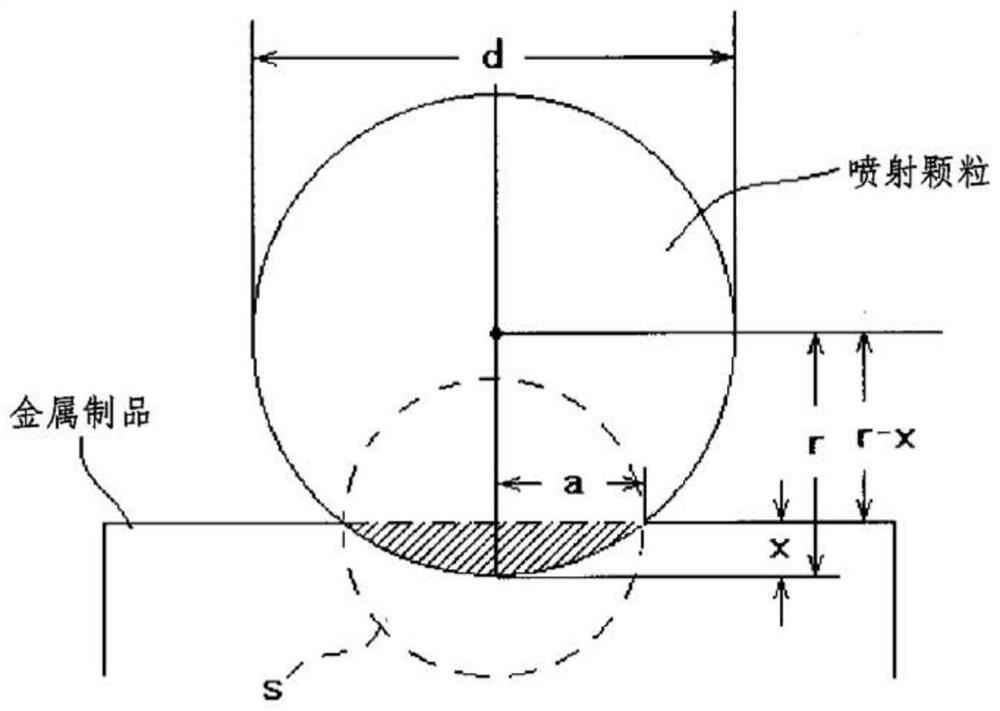

[0102] On the other hand, considering that in order to generate a nanocrystalline structure, it is necessary to impart a deformation exceeding a critical value to the vicinity of the surface of the metal product, in order to provide a deformation exceeding the critical value, it is necessary to apply a large impact force to the surface of the metal product through the collision of the sprayed particles .

[0103] However, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com