Method for shot peening a gas carburised steel

a gas carburized steel and peening technology, applied in the field of shot peening, can solve the problem that the methods of these studies are difficult to apply to gas carburized steel with a soft layer on the surface, and achieve the effect of high compressive residual stress and high fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]Below, the embodiments of the present invention are described with reference to the drawings.

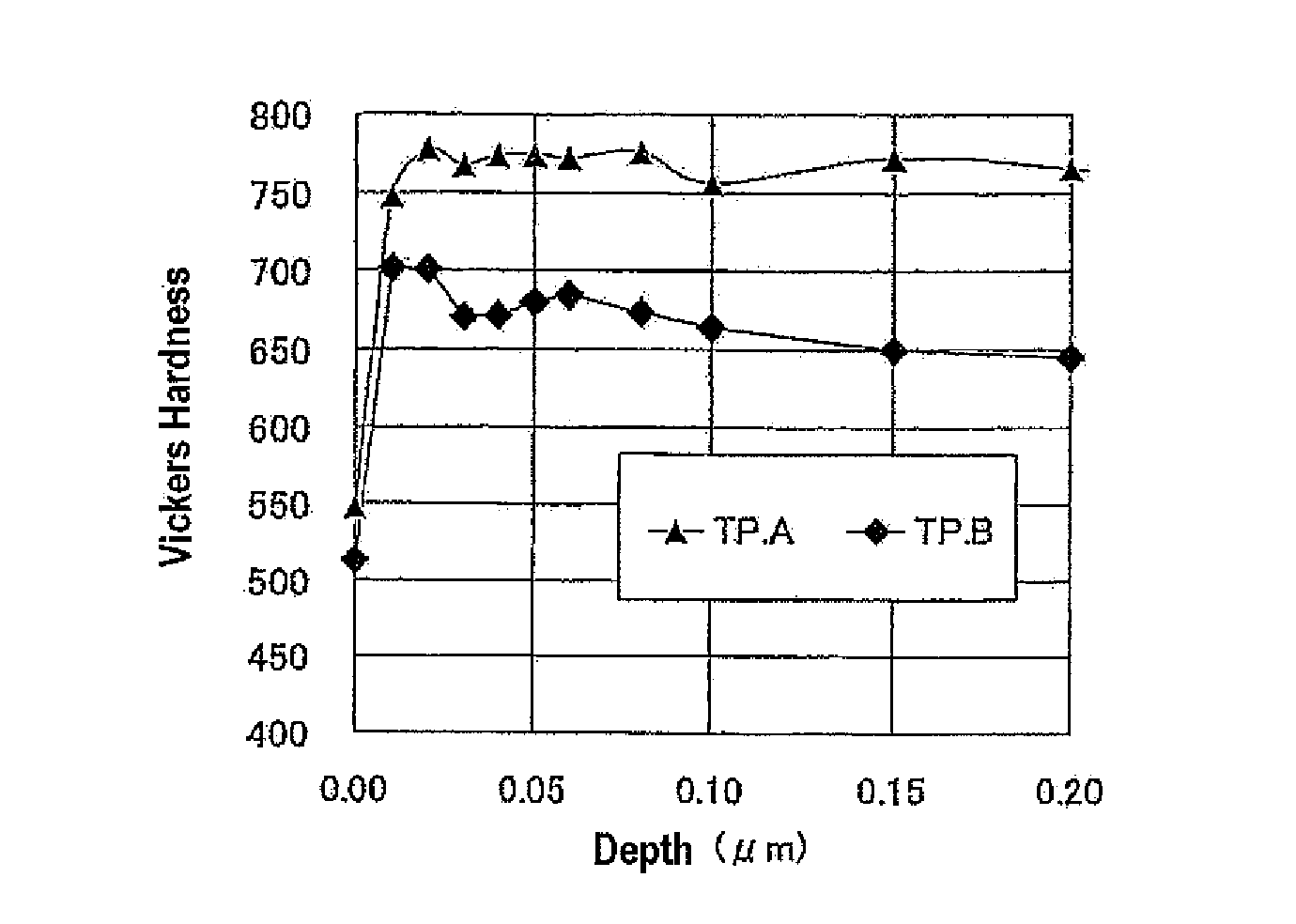

[0028]FIG. 1 is a graph showing the distribution of the hardness of the processed steels that were used in the embodiments. The abscissa denotes depths (micrometer) from the surface of the steel, and the ordinate denotes the Vickers hardness. A gas carburized steel is used for the processed steels. In the drawing, “TP.A” and “TP.B” denote the steels which have been tempered at 180 degree C. and 180 degree C., respectively.

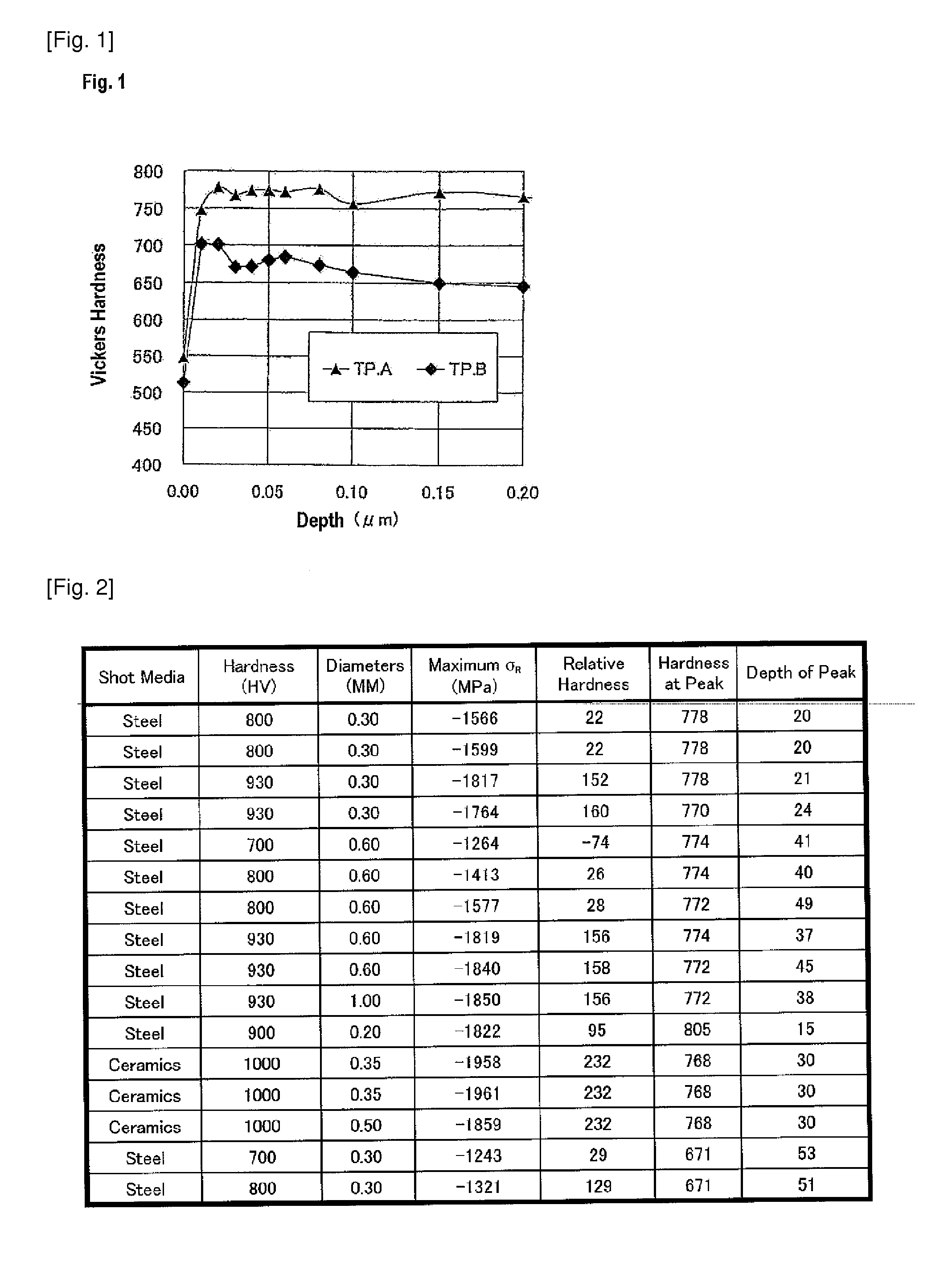

[0029]FIG. 2 is a table showing the conditions and the results of shot peening that were used in the embodiments. A compressive-air shot peening system was used. Shot media that have a hardness of 700 HV to 1,000 HV and diameters (the mean diameters) of 0.2 to 1.0 mm were used.

[0030]The

“Maximum σR”

in the table denotes the maximum compressive residual stresses in the processed steels. The compressive residual stresses were measured by using a micro-stress analyzer that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com