Gas intensifier with lubrication

A supercharger and gas pressure technology, applied in fluid pressure converters, lubricating pumps, lubricating parts, etc., can solve problems such as high maintenance costs, equipment temperature rise, and low durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

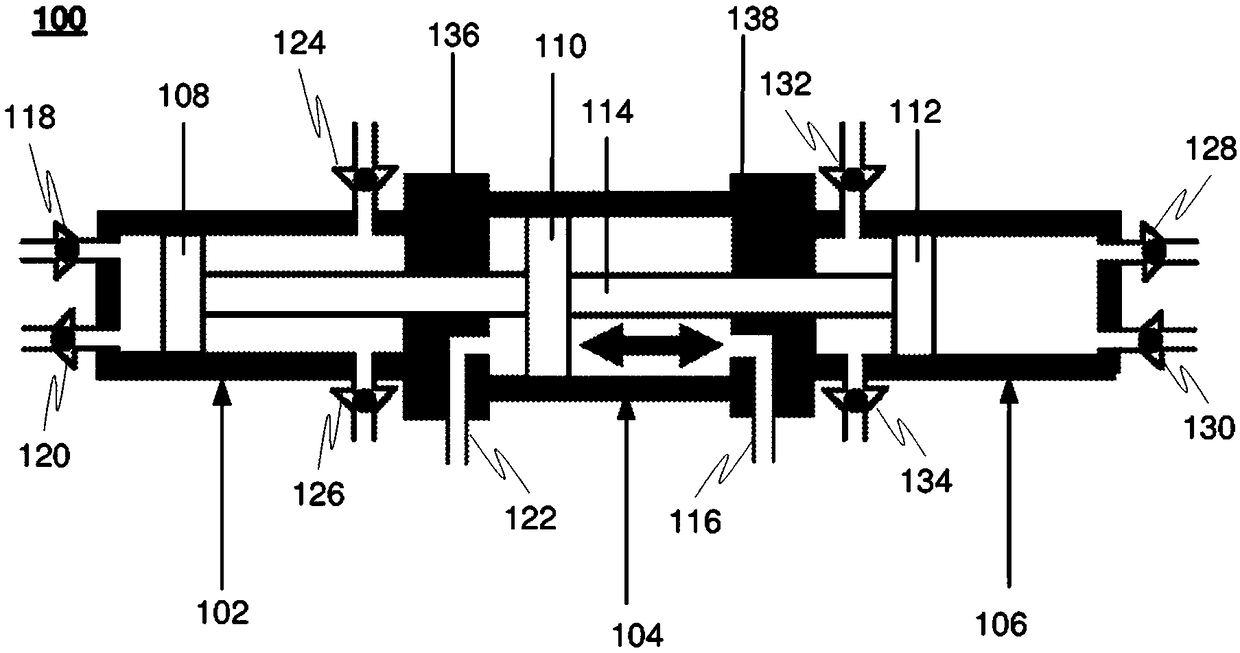

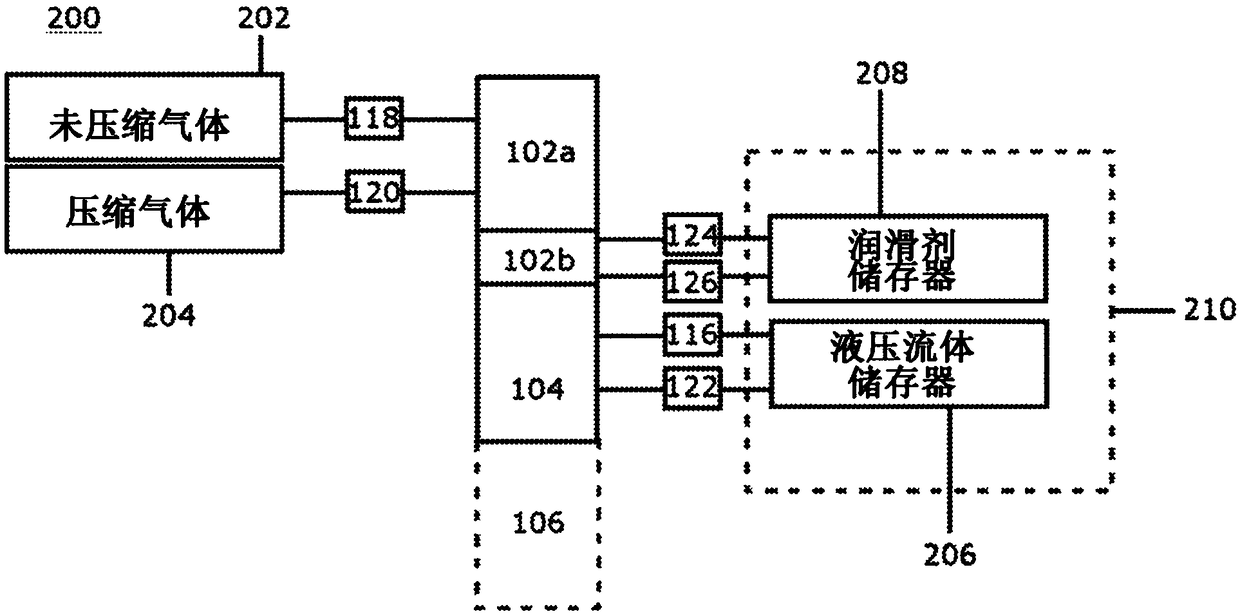

[0013] figure 1 An embodiment of a compressor arrangement according to the invention, preferably in the form of a supercharger or "booster", intended for increasing the pressure of a gas is depicted. In other words, gas compression using a compressor device is the subject of discussion. In some embodiments, the gas whose pressure can be increased using a booster or compressor can include biogas or natural gas.

[0014] The term "supercharger unit" refers hereinafter to a supercharger device comprising one (common) body, preferably of rigid type. In some embodiments, a body may be of a substantially monolithic nature, defined by a single element or a plurality of permanently connected elements. In some other embodiments, the body may comprise multiple functional elements, such as chambers detachably connected together by necessary fixing elements such as bolts.

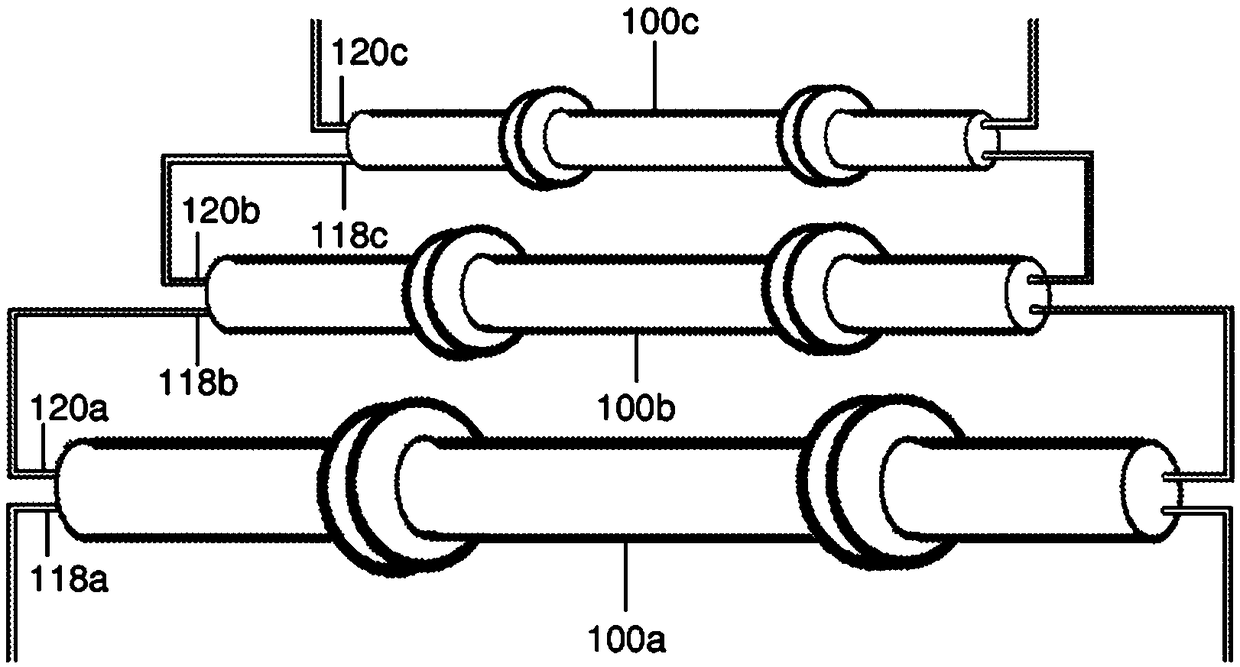

[0015] In the embodiment shown, a single-stage double-acting booster unit is provided, but the basic principles o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com