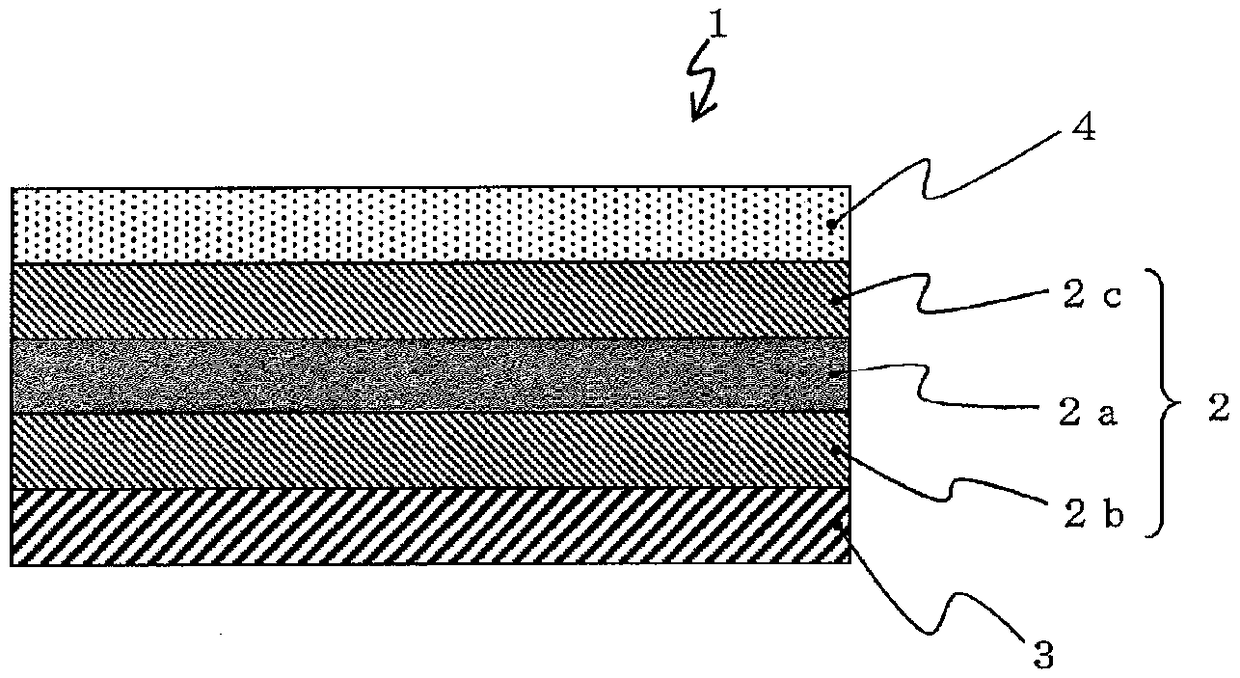

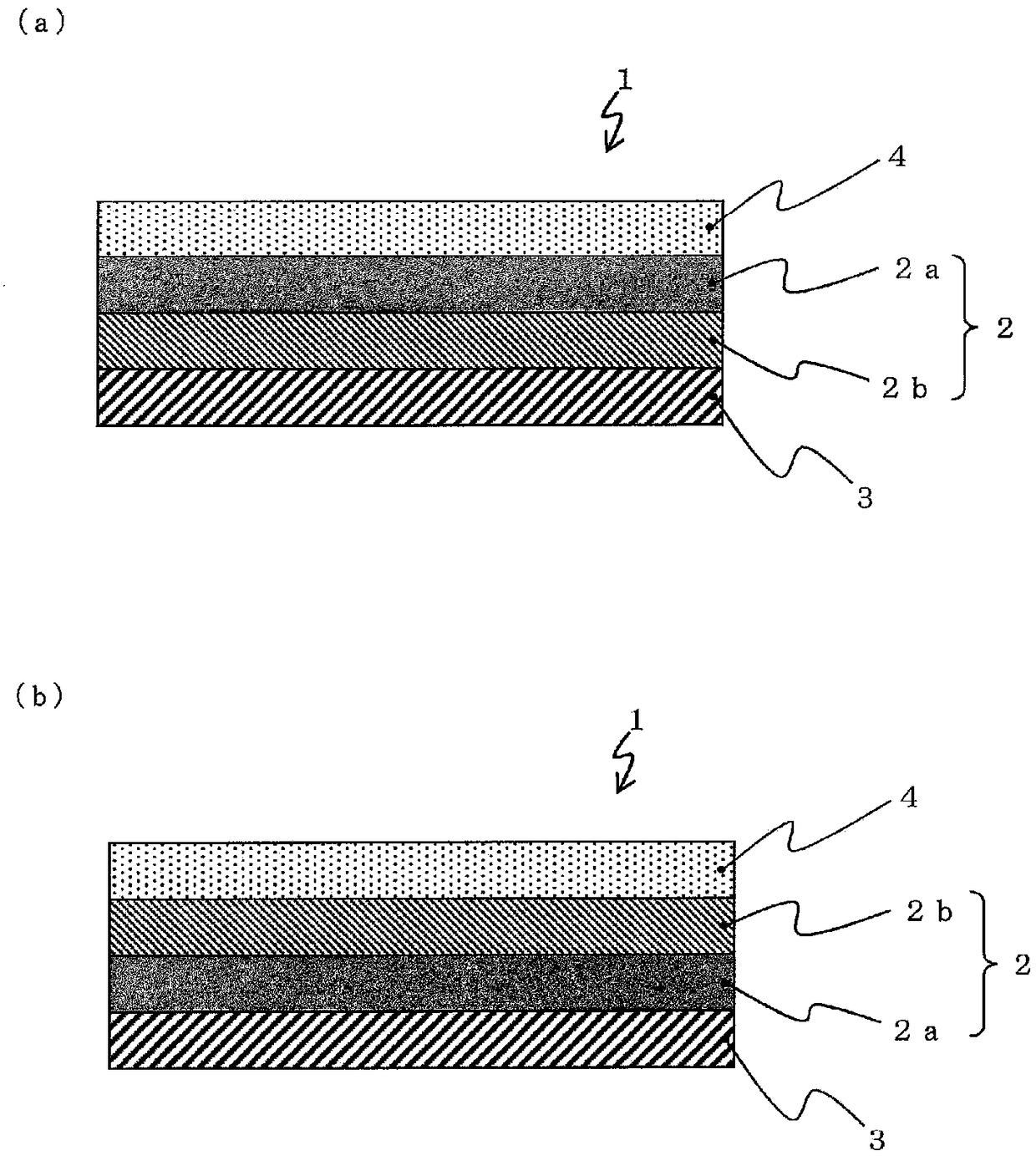

Multilayer film and image display device

A laminated film and polarizing film technology, applied in the direction of layered products, synthetic resin layered products, electronic equipment, etc., can solve problems such as cracks, low durability, warping, etc., achieve high white brightness, improve white brightness, optical The effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

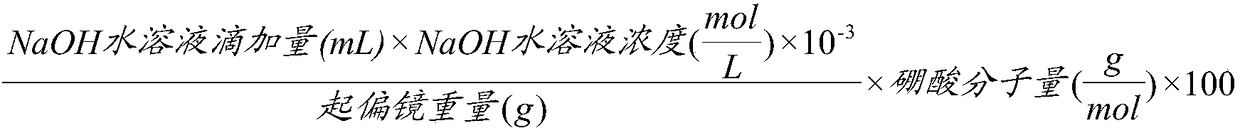

manufacture example 1

[0131] Production Example 1 (Production of polarizer (1) with a thickness of 5μm)

[0132] A laminate having a 9μm thick PVA layer formed on an amorphous PET substrate was subjected to auxiliary stretching in a gas atmosphere at a stretching temperature of 130°C to form a stretched laminate, and then the stretched laminate was immersed in iodine / In a 0.3% aqueous solution of potassium iodide (weight ratio = 0.5 / 8), a colored laminate is formed, and the colored laminate is further stretched in an aqueous boric acid solution at a stretching temperature of 65°C to achieve a total stretching ratio of 5.94 times. An optical film laminate including a PVA layer having a thickness of 5 μm, which was stretched integrally with an amorphous PET substrate, was formed. An optical film laminate including a PVA layer (polarizer) (1) with a thickness of 5 μm, which constitutes a highly functional polarizing film, is formed. The optical film laminate is formed on an amorphous PET substrate by su...

manufacture example 2

[0133] Production Example 2 (Production of Polarizer (2) with a thickness of 5μm)

[0134] Except that the concentration of iodine / potassium iodide (weight ratio=0.5 / 8) was changed to 0.2%, an optical film laminate including a PVA layer (polarizer) (2) having a thickness of 5 μm was formed in the same manner as in Production Example 1. The transmittance of the PVA layer of the obtained optical film laminate was 44.0%, and the boric acid content was 23% by weight.

manufacture example 3

[0135] Manufacturing example 3 (manufacturing of polarizer (3) with a thickness of 5μm)

[0136] Except that the concentration of iodine / potassium iodide (weight ratio=0.5 / 8) was changed to 0.23%, an optical film laminate including a PVA layer (polarizer) (3) having a thickness of 5 μm was formed in the same manner as in Production Example 1. The transmittance of the PVA layer of the obtained optical film laminate was 43.7%, and the boric acid content was 23% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com