Automatic cleaning and impurity removing machine of bamboo shoots

An automatic cleaning and washing machine technology, applied in application, food processing, food science and other directions, can solve the problems of difficult to guarantee hygiene quality, low work efficiency, troublesome cleaning process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

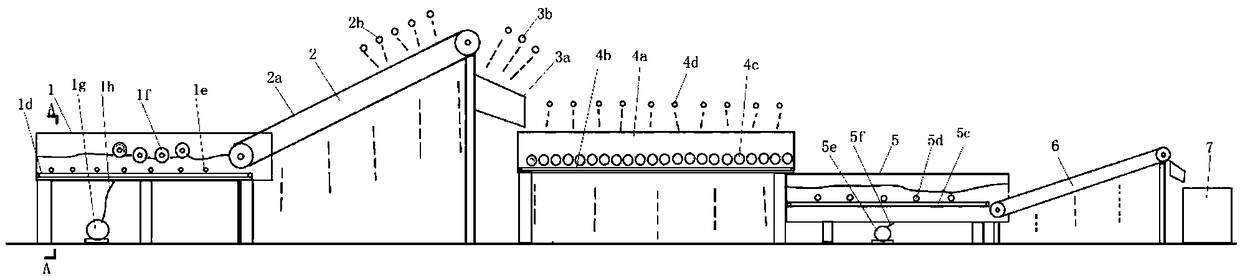

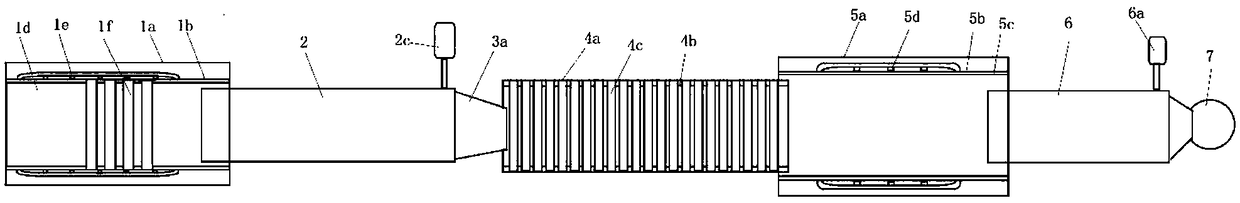

[0018] Such as Figure 1 ~ Figure 3 Shown, the bamboo shoots automatic cleaning and impurity removal machine of the present invention comprises the washing tank 1 arranged in sequence, the climbing type diluting conveying cleaning machine 2, the overturning cleaning mechanism, the desilting cleaning tank 4, the air bubble cleaning tank 5, and the water filter conveyor 6 , collection bucket 7. To see more clearly, figure 2 The primary cleaning spray pipe 2b, the secondary cleaning spray pipe 3b and the three cleaning spray pipe 4d are not shown in the drawing.

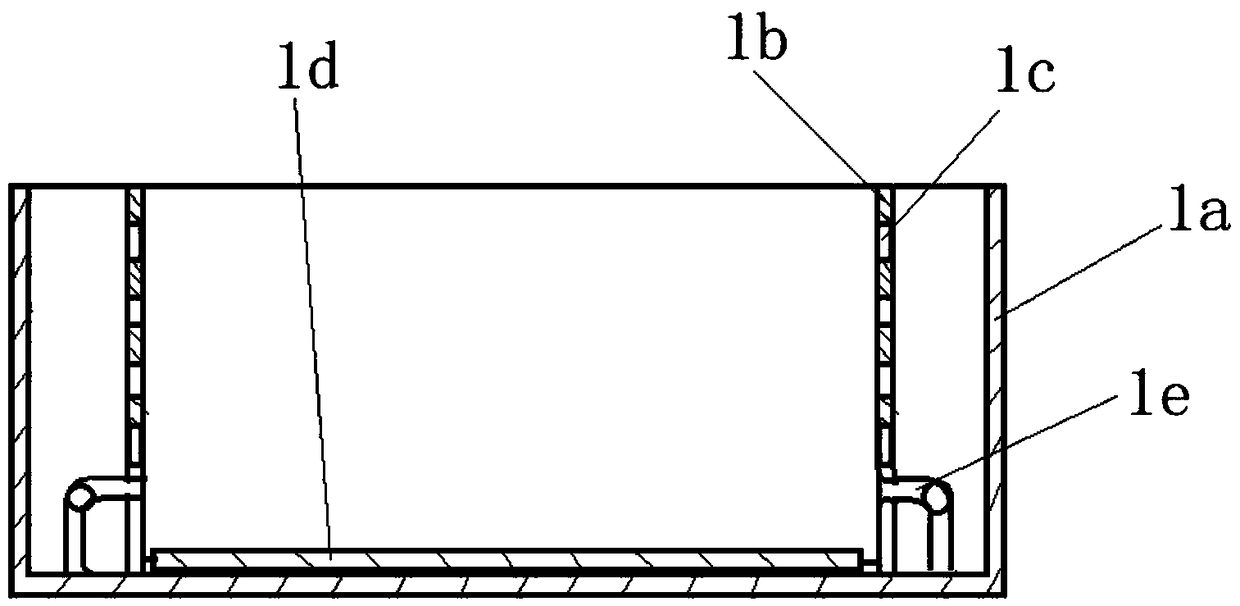

[0019] Described scrubbing tank 1 comprises rubbing with the hands outer tank 1a and the scrubbing inner tank 1b of tank wall band mesh 1c, the first conveyor chain plate 1d that is arranged on the bottom of the tank, the first bubble generating device 1e that is arranged on the tank wall, in scrubbing The upper part of the tank is arranged with a group of horizontal scrubbing rollers 1f whose two ends are installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com