Three-layer production line for wall production

A production line and wall technology, which is applied in the direction of mechanical conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of small annual output of the production line, low degree of automation, and difficulty in guaranteeing the quality of the wall, and achieve large carrying capacity, Simple structure and high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further described below in conjunction with accompanying drawing:

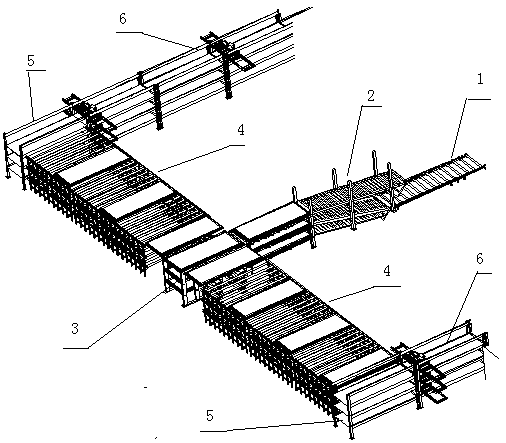

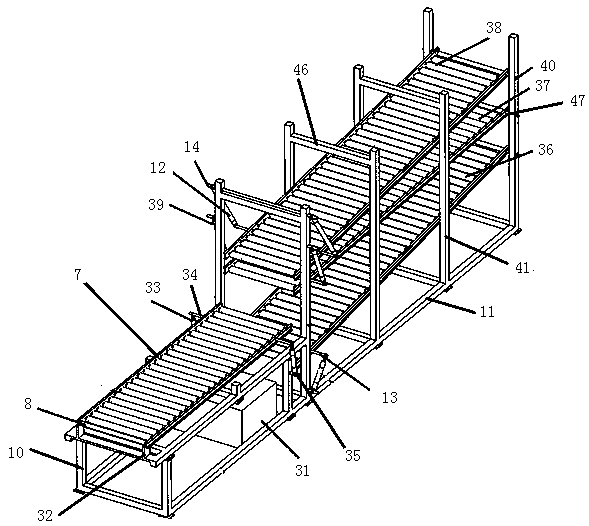

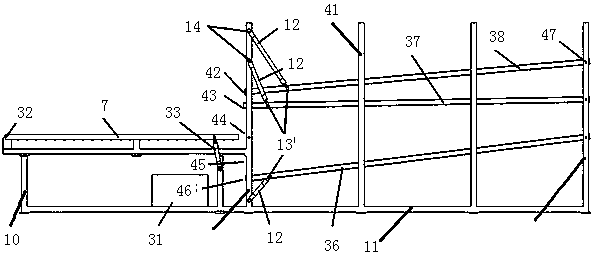

[0027] As shown in the attached figure, a three-layer production line for wall production is provided with a base, which is characterized in that a layer of mold conveying line 1, a three-layer layer changing machine 2, and a three-layer two-way turning are sequentially arranged on the base of the production line Machine 3, three-layer mold return line 4, three-layer one-way turning machine 5 and three-layer paving line 6, the one-layer mold conveying line 1 is composed of one layer of wallboard guide assembly, and the wallboard guide assembly It is composed of a connecting rod 7, a guide roller 8 and a bracket 9. The two ends of the guide roller 8 are respectively hinged with the connecting rod 7. The connecting rods 7 are respectively fixed on the base through the bracket 9, and the guide roller 8 rolls to drive the wallboard to move. The described three-layer changing layer m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com