Automatic pickup and placement assembling mechanism for soft PCB

A PCB board and automatic picking technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of rough edges of finished soft PCBs and inconsistent heights around the boards, etc., to prevent the generation of unqualified products and improve labor productivity , The effect of preventing leakage installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

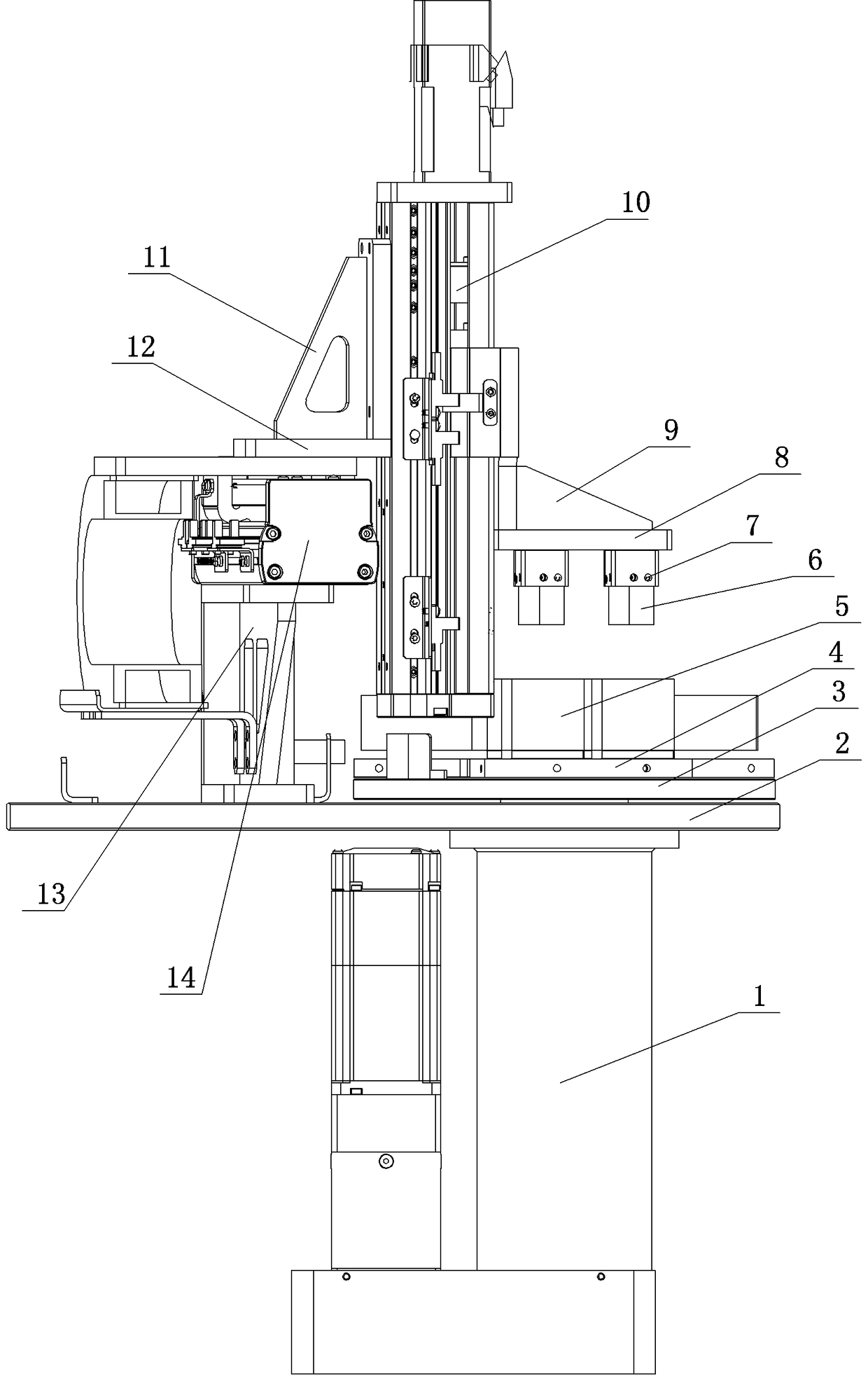

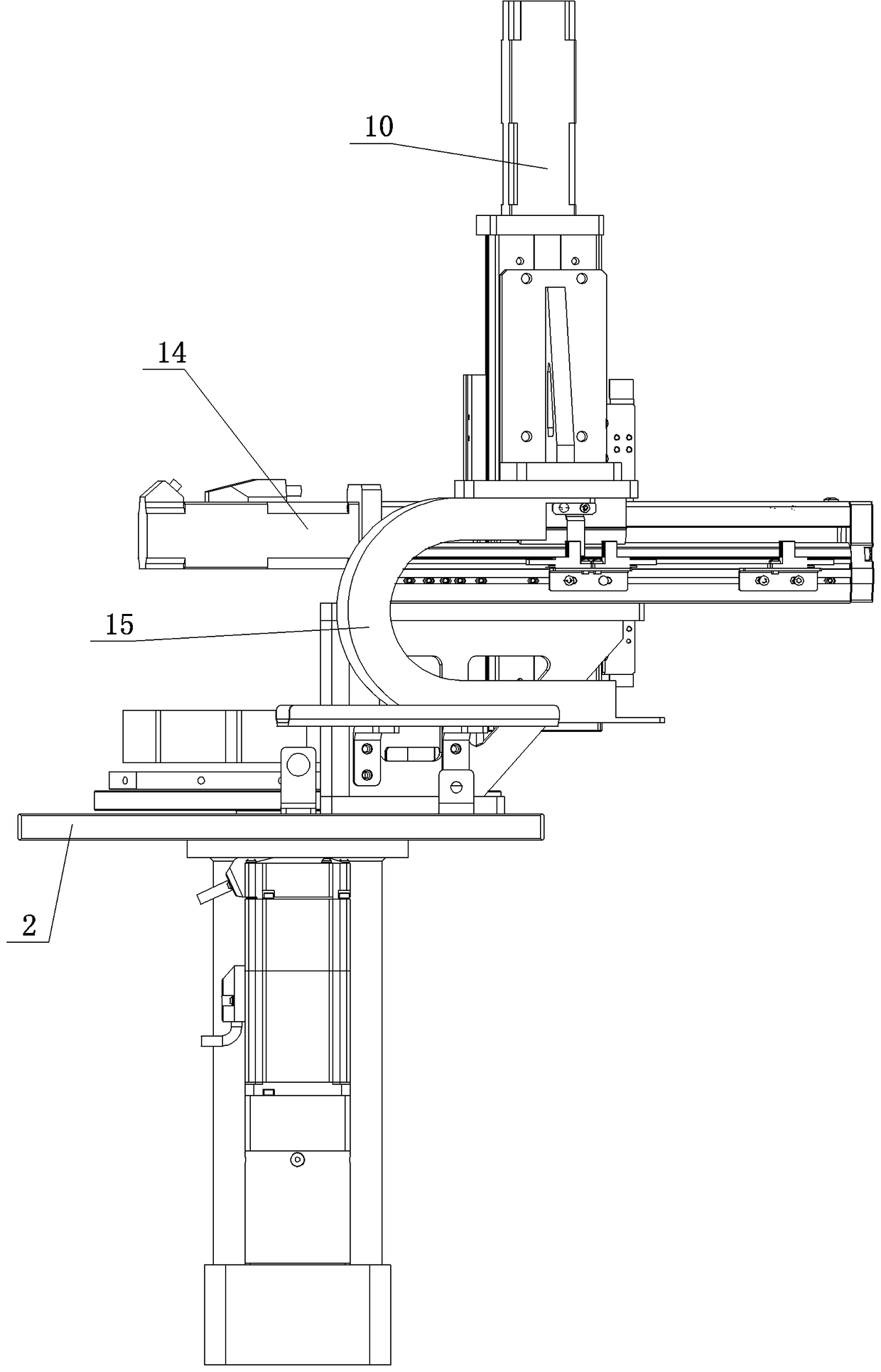

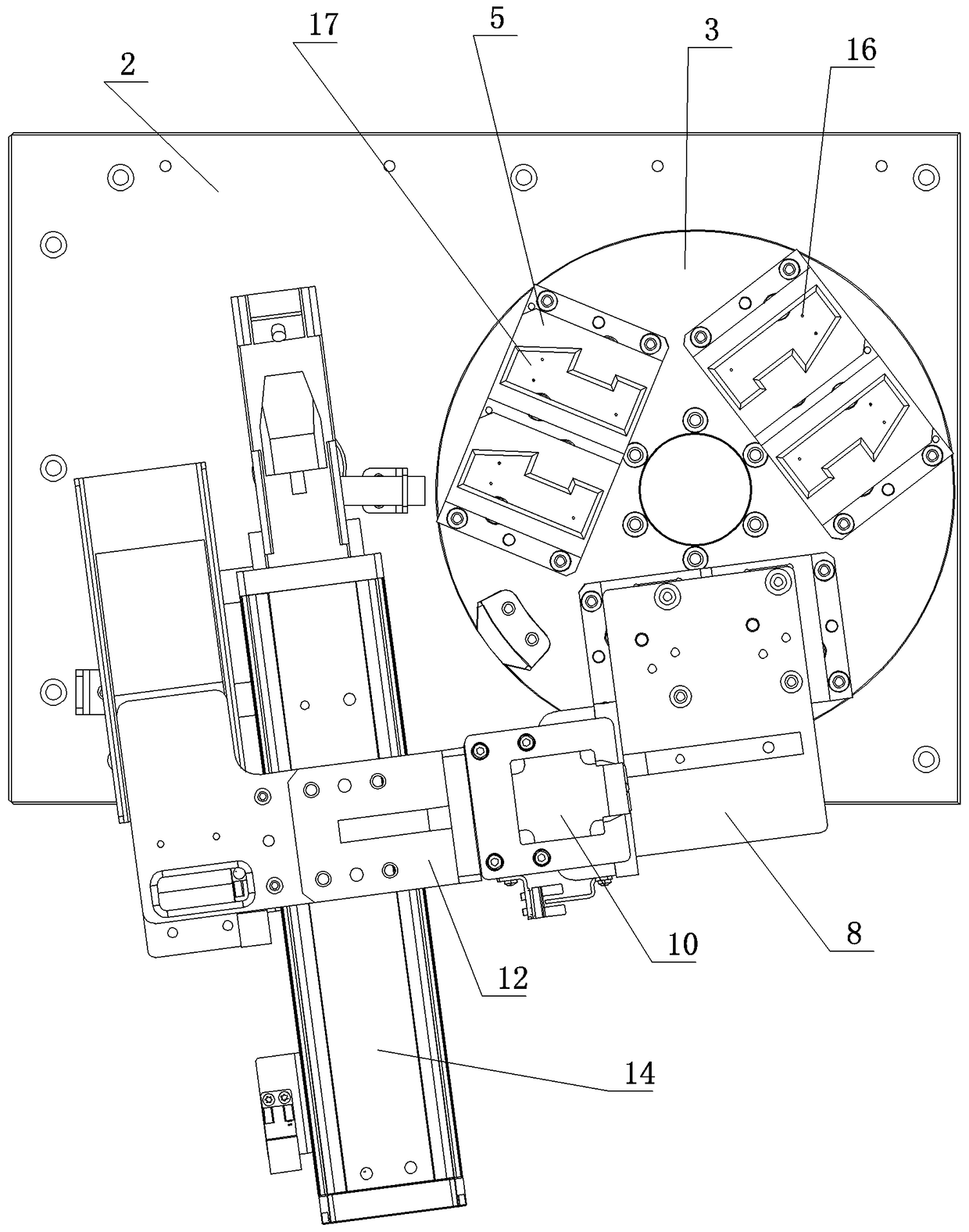

[0051] As shown in the figure, the present invention includes a fixed platform, a PCB board placement box whose inner wall contour corresponds to the shape of the soft PCB board, and a pick-up head whose suction surface shape corresponds to the shape of the soft PCB board. The upper end of the fixed platform is provided with a transverse transmission mechanism and The turntable, the longitudinal transmission mechanism is arranged on the horizontal transmission seat of the horizontal transmission mechanism, and the pick-up suction head is arranged on the longitudinal transmission seat of the longitudinal transmission mechanism; the lower end of the fixed platform is provided with a turntable transmission mechanism;

[0052] The turntable is set under the pick-up head, and multiple PCB board placement boxes are evenly distributed on the turntable along the circumferential direction;

[0053]The suction port on the upper end of the pick-up head is connected to the suction port of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com