A kind of ball milling processing raw material to synthesize high-purity ti 3 b 2 nMaterial method

A high-purity, raw material technology, applied in chemical instruments and methods, boron compounds, inorganic chemistry, etc., can solve the problems of high impurities in N samples, and achieve the effects of fast diffusion, reduced content, and fast reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] This embodiment provides a kind of ball mill treatment raw material synthetic high-purity Ti 3 B 2 N material method, preparation of Ti 3 B 2 The method of N includes the following steps:

[0077] 1) Weigh nano-Ti powder, amorphous B powder and hexagonal BN powder respectively, and set aside;

[0078] And the molar ratio of the three raw materials of the nano-Ti powder, the amorphous B powder and the hexagonal BN powder Ti: B: BN=3: 1: 1;

[0079] 2) put the nano-Ti powder, amorphous B powder and hexagonal BN powder weighed in step 1) into a ball mill jar, and the grinding balls adopt agate balls, and agate balls include large balls and small balls, and the diameters of large balls and small balls are 15mm and 5mm respectively, the number ratio of large balls and small balls is 1:5, and the weight ratio of balls to water is 2:1:1, the speed of the ball mill is 300r / min, and the ball mill tank is filled with Ar gas inert gas as a protection Inert gas, ball milled on...

Embodiment 2

[0085] The difference between this embodiment and embodiment 1 is that the ball milling time in step 2) is 60 h, and the other preparation steps are the same as in embodiment 1, and will not be repeated here.

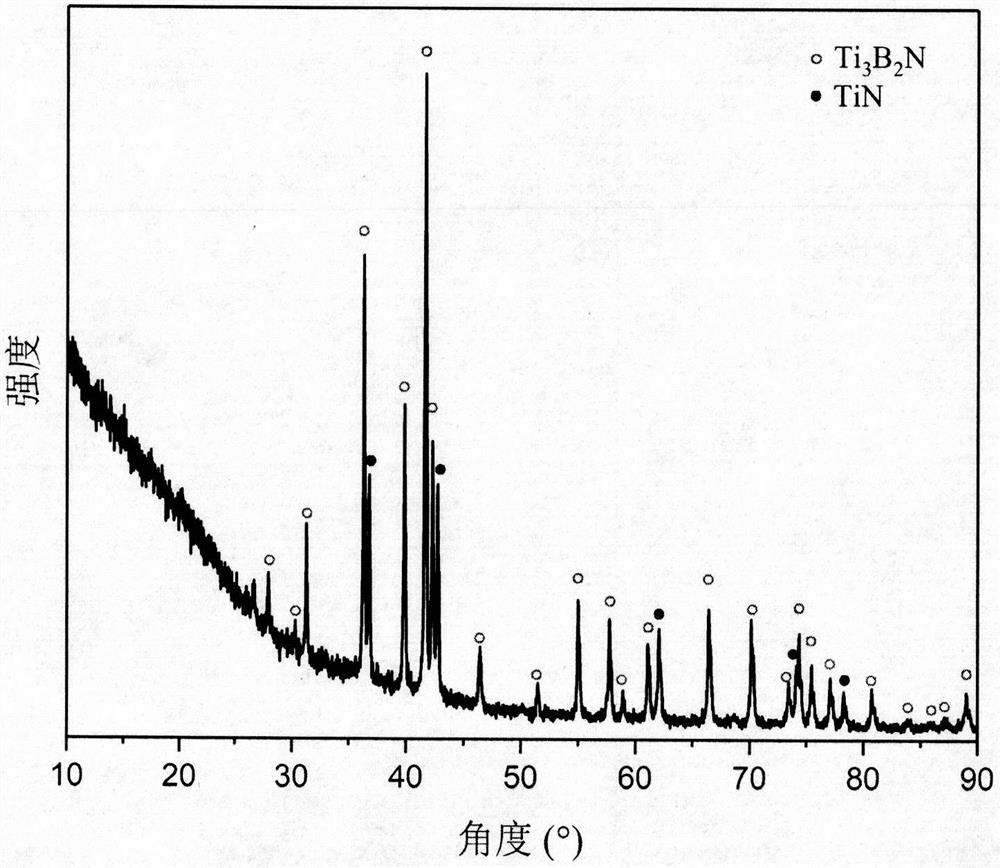

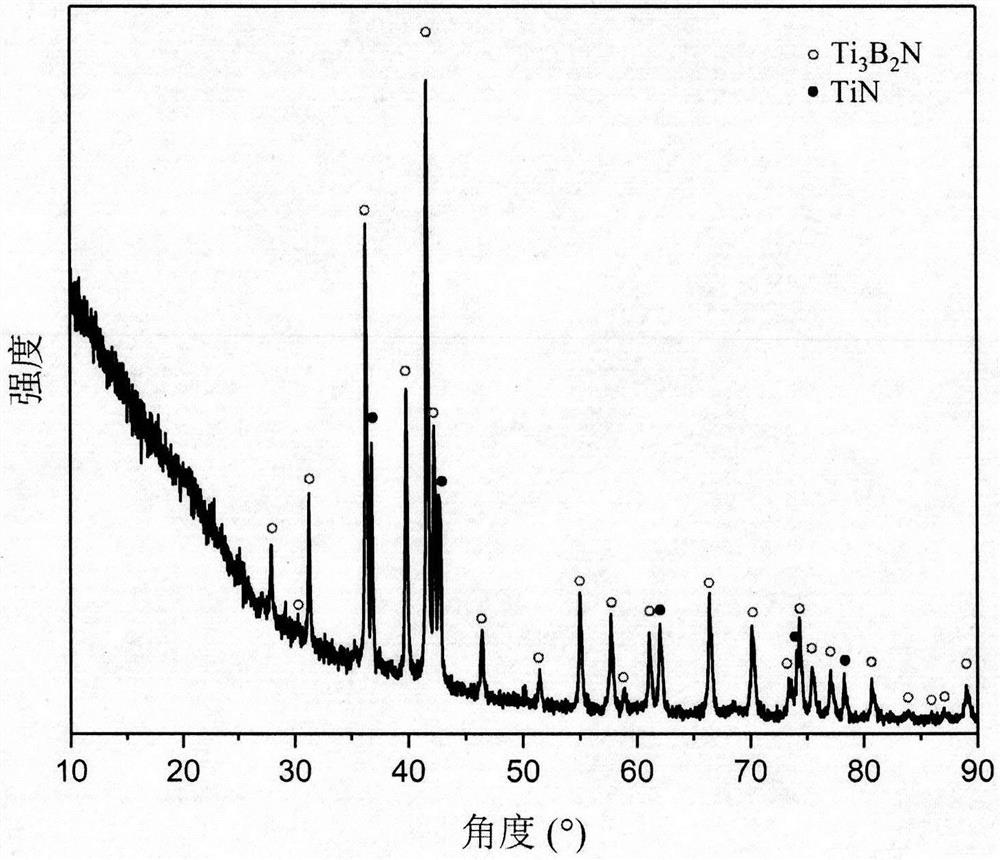

[0086] The product XRD spectrum that this embodiment prepares sees image 3 , containing Ti 3 B 2 Two phases of N and TiN, and the XRD pattern in Example 1 shows that the sample also contains Ti 3 B 2 There are two phases of N and TiN, and the ratio of the two phases basically does not change. It shows that when other parameters are the same, the ball milling time is 48 or 60h. Ti 3 B 2 N sample; at the same time, after ball milling for a certain time to make the raw material amorphized, increasing the ball milling time cannot continue to improve Ti 3 B 2 The purity of the N material.

Embodiment 3

[0088] The difference between this example and Example 1 lies in: in step 4), the temperature is raised to 1200° C. at a rate of 8° C. / min under a nitrogen atmosphere; other preparation steps are the same as those of Example 1, and will not be repeated here.

[0089] The XRD pattern of the sample prepared in this embodiment is shown in Figure 4 , containing Ti 3 B 2 N and TiN two phases, the XRD patterns of Example 3 and Example 1 are similar, indicating that under the same conditions of other parameters, the sintering temperature of 1250 ° C and 1200 ° C can obtain Ti 3 B 2 N samples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| shear modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com