Method and system for separating waste for cement production

A waste and cement technology, applied in cement production, etc., can solve the problems of uneven particle size, high moisture, low calorific value, etc., and achieve the effects of long residence time, energy saving, efficiency and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

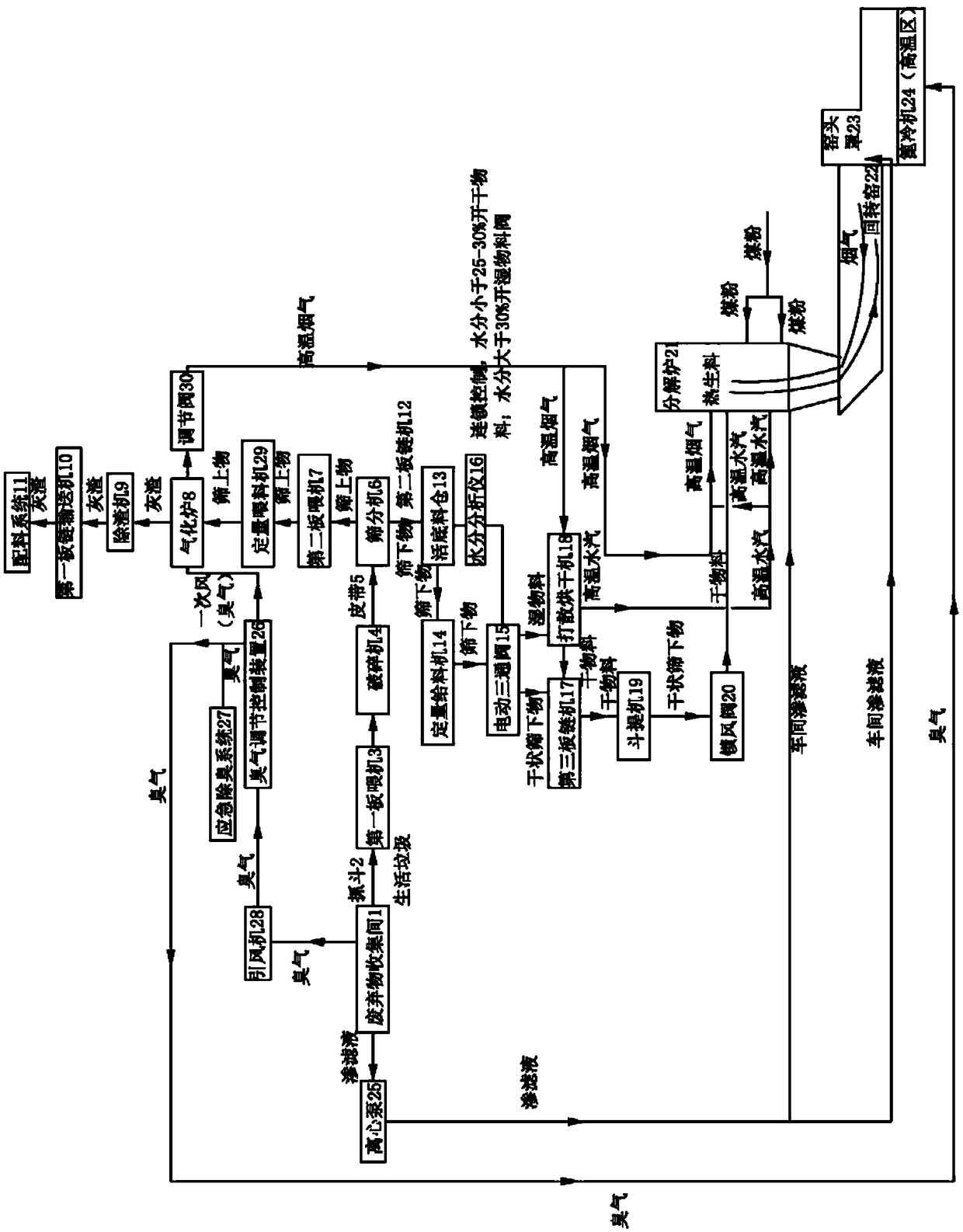

[0126] Such as figure 1 As shown, this embodiment provides a method for separating waste into cement production, firstly separating the waste into large particle waste and small particle waste, and then separating the large particle waste through heating and gasification The high-temperature flue gas and inorganic ash are discharged, and then the high-temperature flue gas is sent to the calciner 21, and the inorganic ash is sent to the batching system 11 for raw materials of the cement kiln.

[0127] In this embodiment, the waste is separated into large particle waste and small particle waste, and then the large particle waste is separated into high-temperature flue gas and inorganic ash through heating and gasification, and then the high-temperature flue gas is sent into the Decomposition furnace is a technical means to send inorganic ash into the batching system to be used as raw material for cement kiln. Therefore, through the double separation of cold and hot domestic wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com