A water surface garbage cleaning ship

A technology for surface garbage and ship cleaning, which is applied to the cleaning of open water, water conservancy projects, special-purpose ships, etc. It can solve the problems that the garbage is not separated from the operator, the cleaning effect of the surface garbage cleaning ship is poor, and the cleaning is time-consuming and laborious. , to achieve the effect of reducing the frequency of repeatedly unloading on the shore, increasing the capture area, and increasing the capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

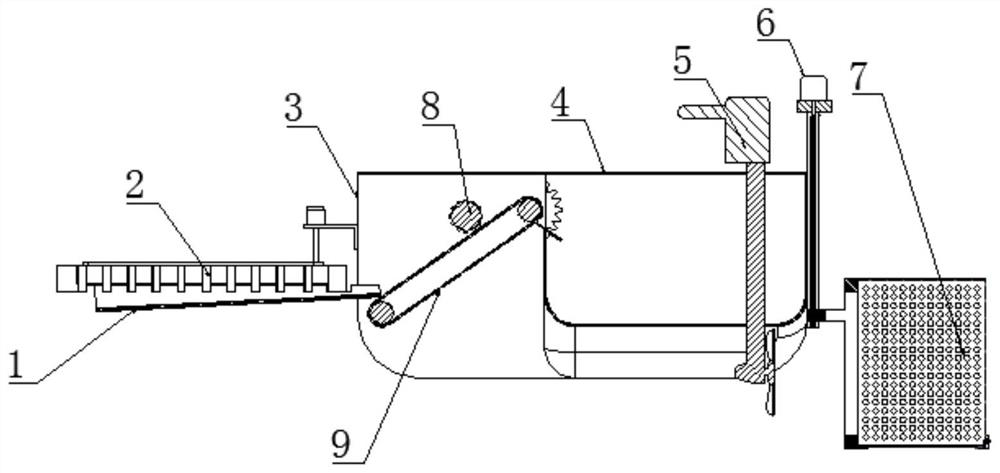

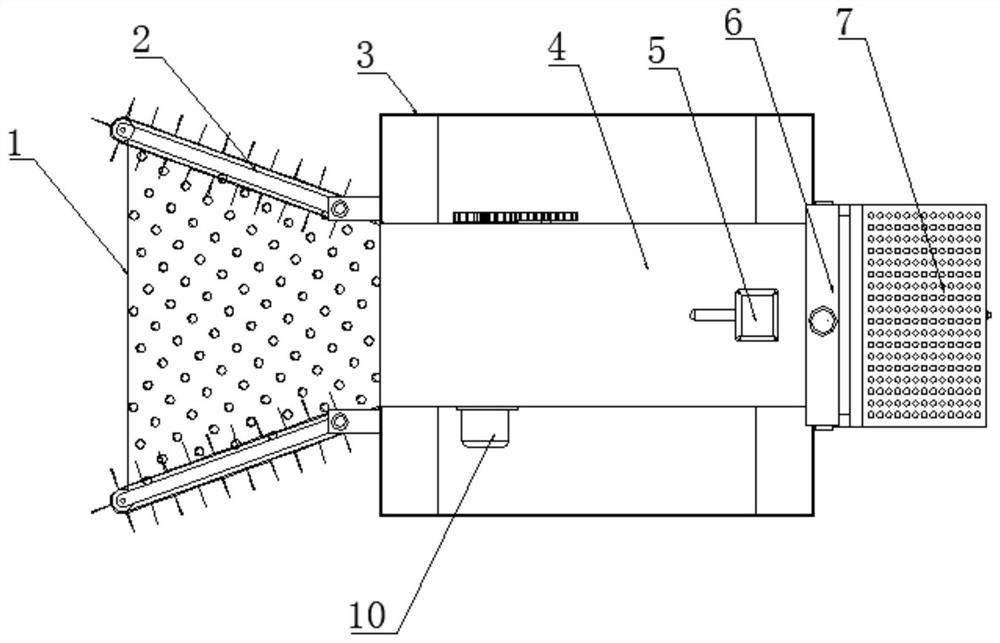

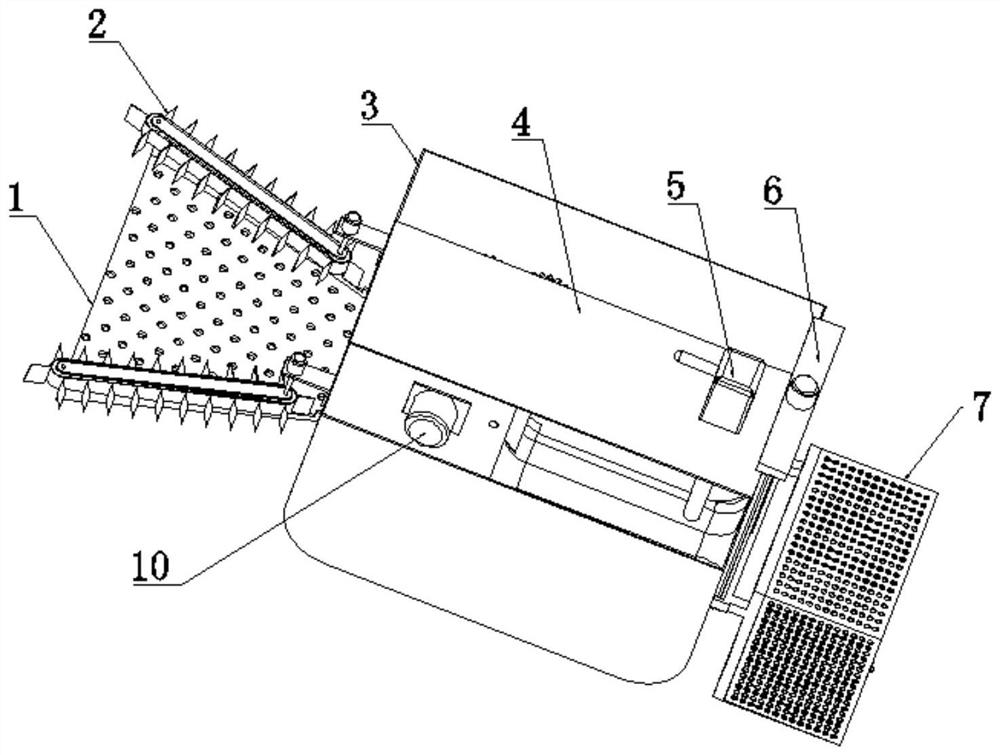

[0040] Embodiment 1, with reference to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 Shown, a kind of water surface rubbish cleaning ship comprises collecting plate 1, hull 3 and cage 7, and the middle position of the left end face of hull 3 is provided with feed inlet 31 and is used for installing roller cylinder 8 and conveyer belt 9, and in feeding The front and rear sides of the feed port 31 are provided with side plates 33 to fix the rolling cylinder 8 and the conveyor belt 9, and the inner side of the hull 3 is provided with a material cavity 34 for storing collected garbage, and the feed port 31 The right end is provided with a material guide plate 32 extending to the inside of the material cavity 34 to guide the garbage transported by the conveyor belt 9 into the material cavity 34, and the middle part of the lower end surface of the hull 3 is provided with a water guide groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com