Wall emulsion paint brushing device for house decoration

A latex paint and wall technology, applied in the direction of construction, building structure, etc., can solve the problem of low work efficiency, and achieve the effect of avoiding difficult cleaning and saving latex paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

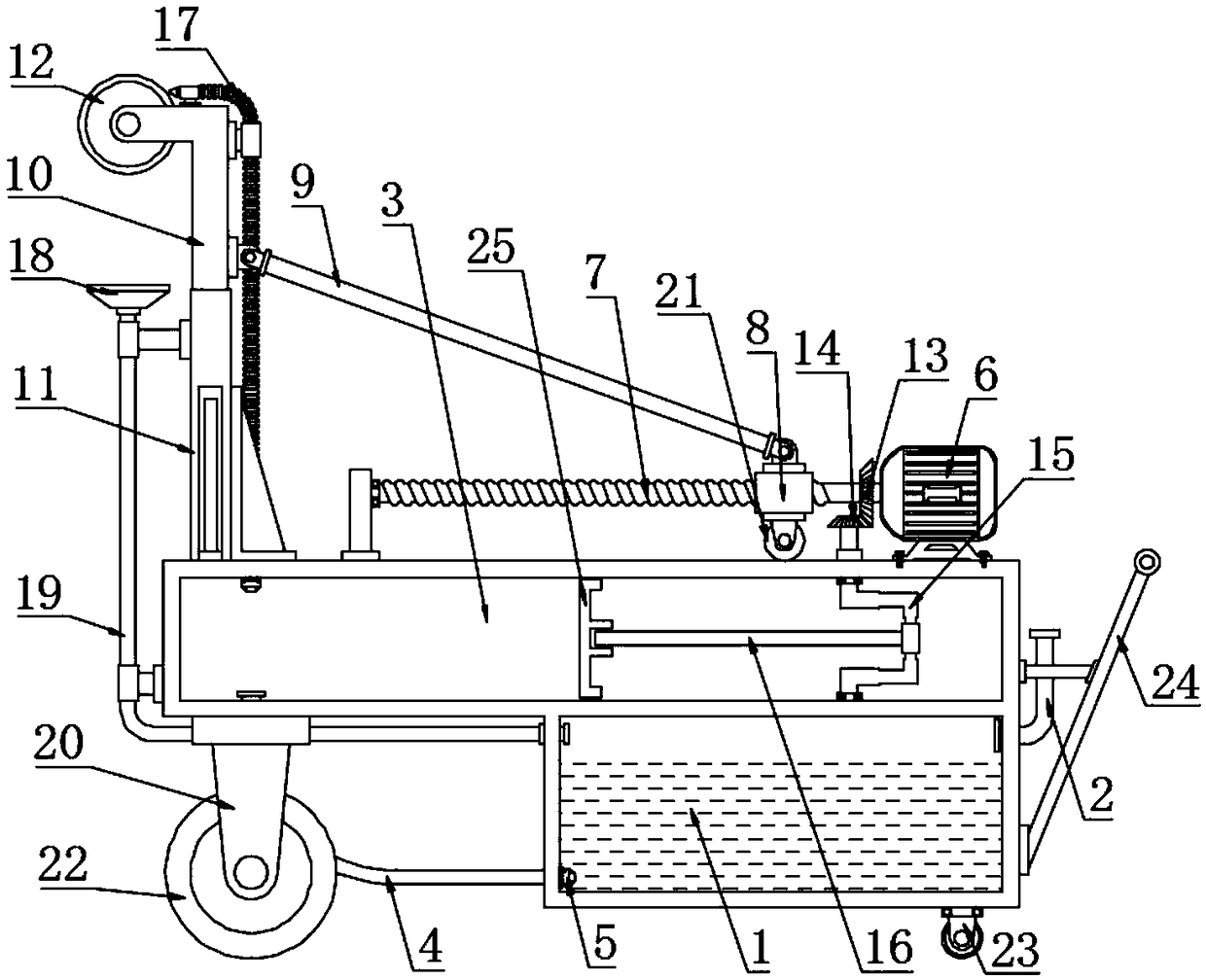

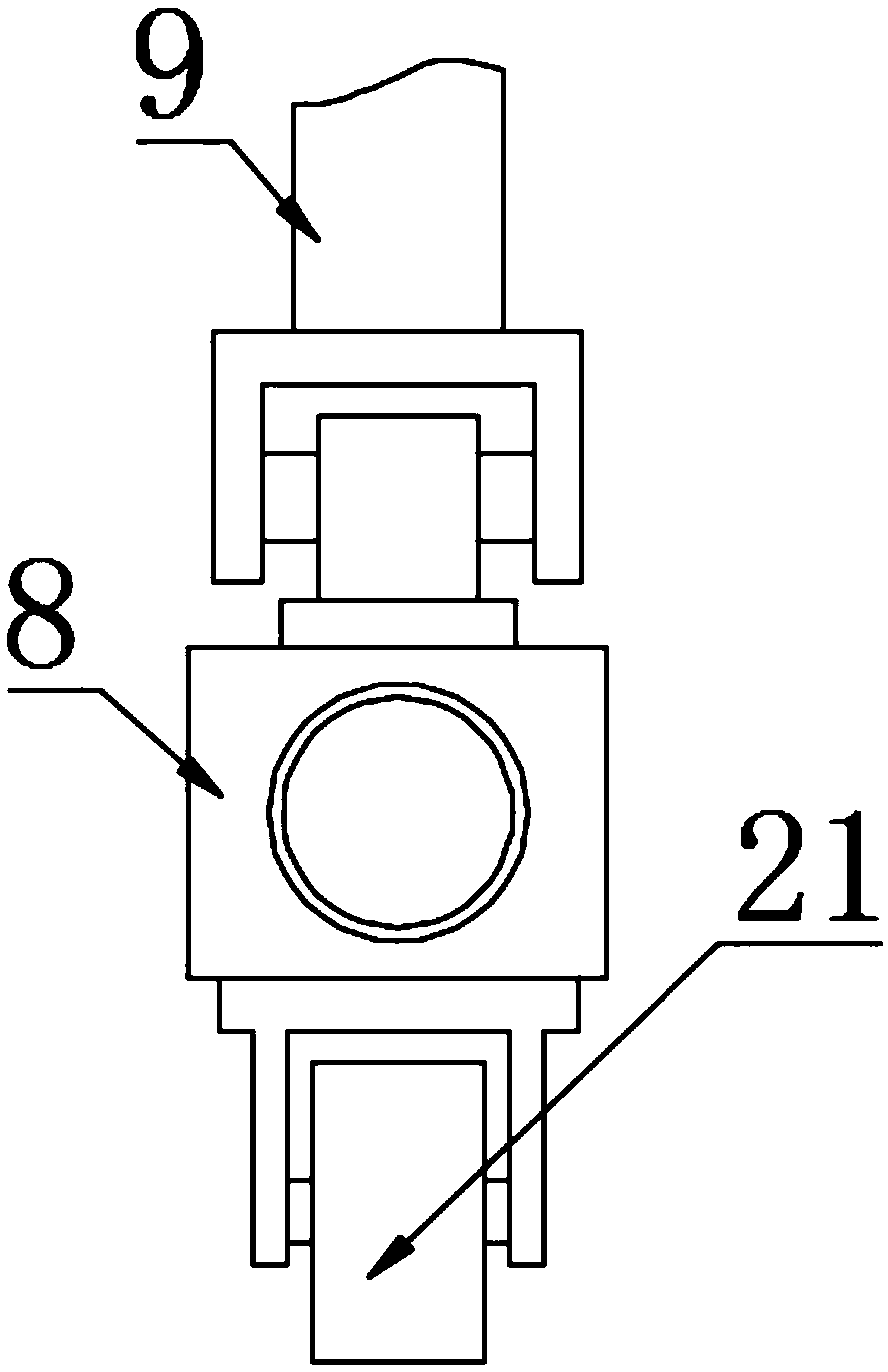

[0021] see Figure 1~3 , in the embodiment of the present invention, a kind of wall latex paint brushing device for house decoration, comprises material box 1, servo motor 6, telescopic frame 10, brush wheel 12 and push handle 24; Said material box 1 top is provided with delivery box 3 , the side wall of the material box 1 is connected and the feeding pipe 3 is fixed, the material box 1 and the conveying box 3 are connected through the discharge pipe 4, and the end of the discharge pipe 4 is fixedly connected to the one-way valve 5, and the upper part of the conveying box 3 is fixedly connected Servo motor 6, the leads of servo motor 6 are connected to the power supply and switch, the servo motor 6 rotates and connects to the screw rod 7, and latex paint is added to the material box 1 through the feeding pipe 2, and the switch is pressed forward to make the servo motor 6 energize and work to drive the screw rod 7. Forward rotation, press the switch in the reverse direction to ...

Embodiment 2

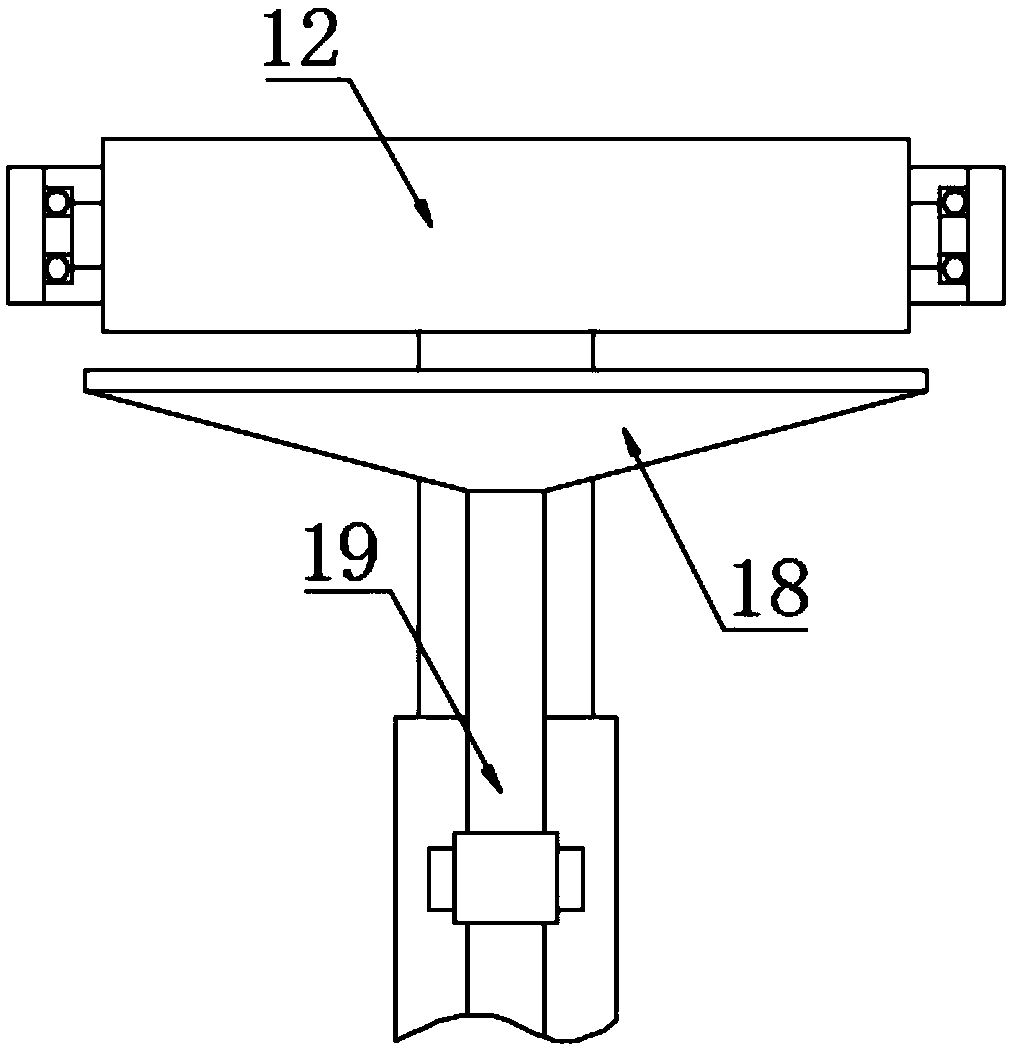

[0024] In order to make the technical solution of this application more complete and detailed, some technical features are added on the basis of the above-mentioned embodiment 1 to make the technical solution of this application more excellent. Specifically, some of the technical features added are that the brush wheel 12 A receiving hopper 18 is provided below, and the lower part of the receiving hopper 18 communicates with and fixes a return pipe 19. The latex paint dripped by the brush wheel 12 is re-transported to the hopper 1 by using the return pipe 19, which avoids the situation that the latex paint that traditional brushing produces drops on the floor and is difficult to clean, and achieves the effect of saving latex paint simultaneously.

[0025] The working principle of the present invention is: add latex paint into the material box 1 through the feeding pipe 2, press the switch in the forward direction to make the servo motor 6 energized and drive the screw rod 7 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com