Redundant driving type multi-safety redundancy steering engine

A margin steering gear, driven technology, applied in the direction of projectiles, self-propelled bombs, offensive equipment, etc., can solve the problems of large structure, large gap, unbalanced load, etc., to increase volume weight, less weight increase, and load. balanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Embodiment: The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

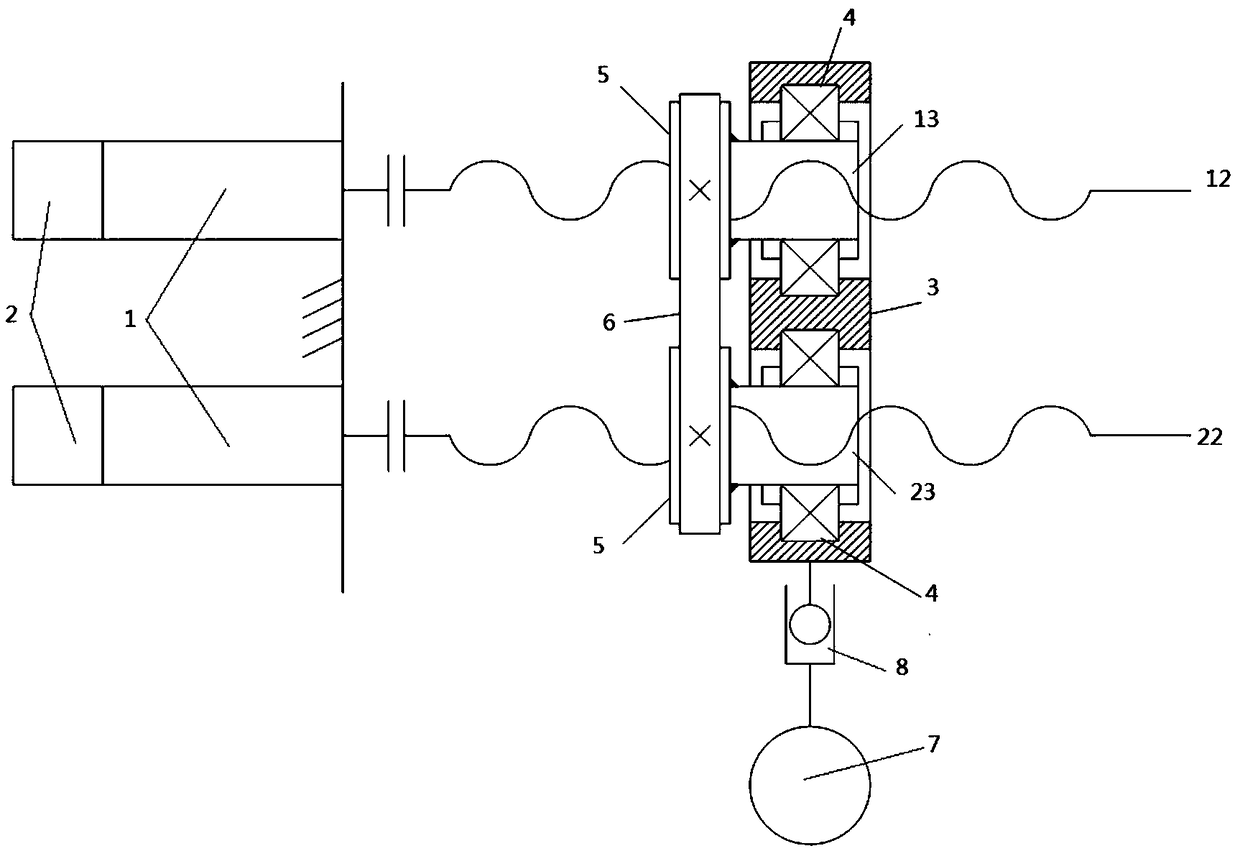

[0024] Such as figure 1 This is the schematic diagram of the redundant drive differential reduction mechanism, explaining how the mechanism synthesizes the speeds of the two motors and outputs the rudder deflection angle. The same rudder surface has two control channels, each control channel includes a driver and a motor 1, two motors 1 with brakes 2 are fixed on the base, the motor 1 is connected with the right-hand screw 12 through a coupling, The second motor is connected with the left-handed screw 22 through a shaft coupling. The inner side of the right-handed nut 13 converts the rotation angle difference with the right-handed screw 12 into translation through the ball and the spiral track, the outer side of the right-handed nut 13 is installed on the cage 3 through the bearing 4 and the retaining ring, and the inner side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com