A method for optimizing aerodynamic matching between full three-dimensional stages of an axial flow compressor

A technology of axial flow compressor and optimization method, which is applied in the field of compressor, can solve the problems of not comprehensively considering the impact, not giving compressor motor blades, and lacking quantitative modification methods, etc., to achieve the effect of improving adiabatic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

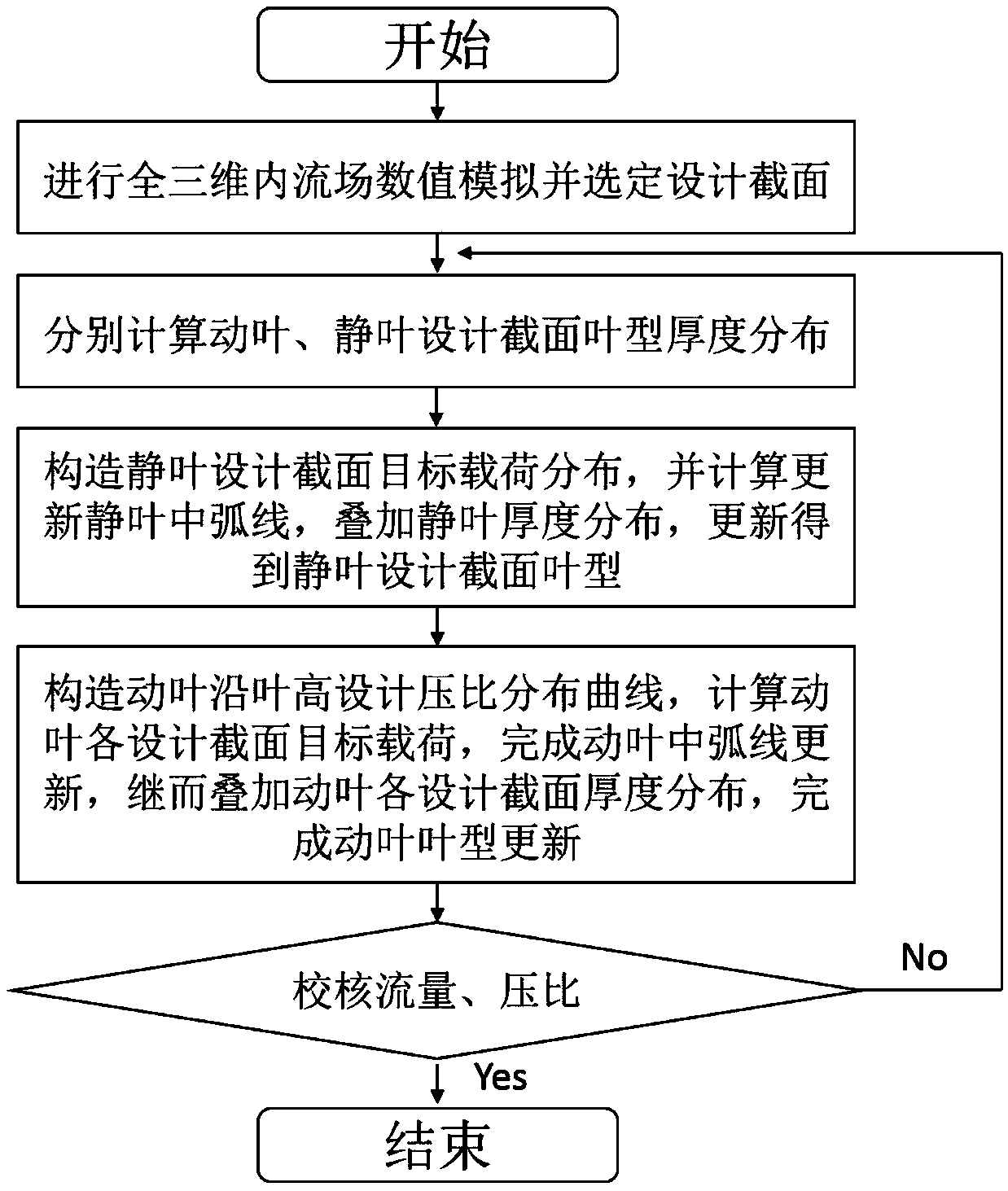

[0029] Step 1: Knowing the spatial geometry coordinates of the blades of the full three-dimensional axial flow compressor, which is called the initial blade geometry, given the total inlet temperature T0, the total inlet pressure P0, the inlet airflow angle α and the outlet back pressure p, for the given For a given axial compressor blade geometry, the Reynolds time-averaged Navier-Stokes equation (RANS) method is used to numerically solve the method. The spatial discretization adopts the JST format based on the center of the mesh body, and the time advancement adopts the hybrid display Rugge-Kutta time advancement scheme, and the turbulence model Using the B-L algebraic turbulence model, the full three-dimensional viscous internal flow field numerical simulation is carried out, and the numerical simulation results of the initial blade geometric flow fie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com