An end cap for an electric motor and a washing machine having the same

A technology of sheet metal brackets and bearing chambers, applied in the field of washing machines, can solve problems such as cracking of assembly plastic packaging materials, loose end caps, and poor noise, and achieve the effects of improving noise, improving assembly stability, and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

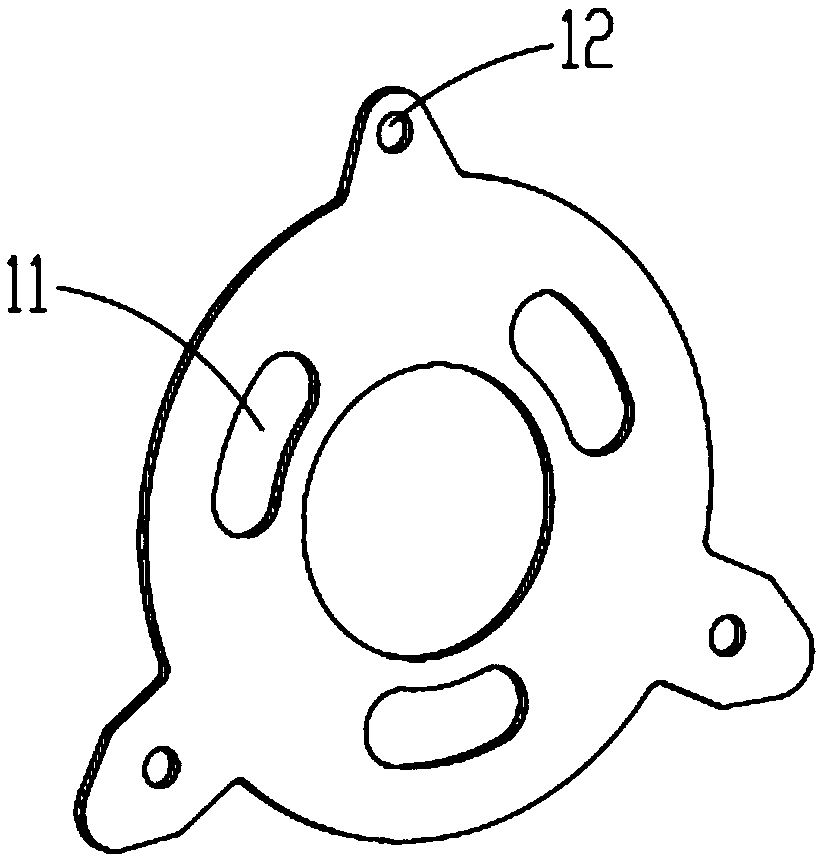

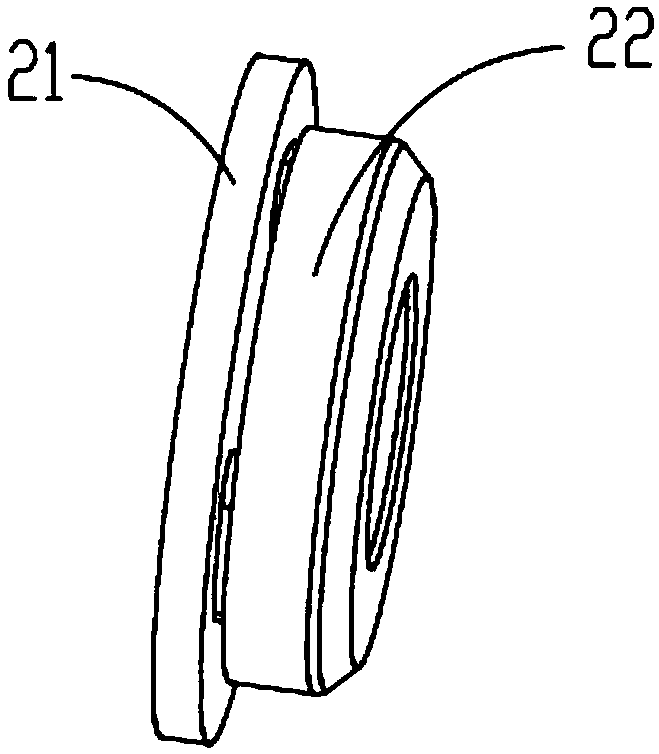

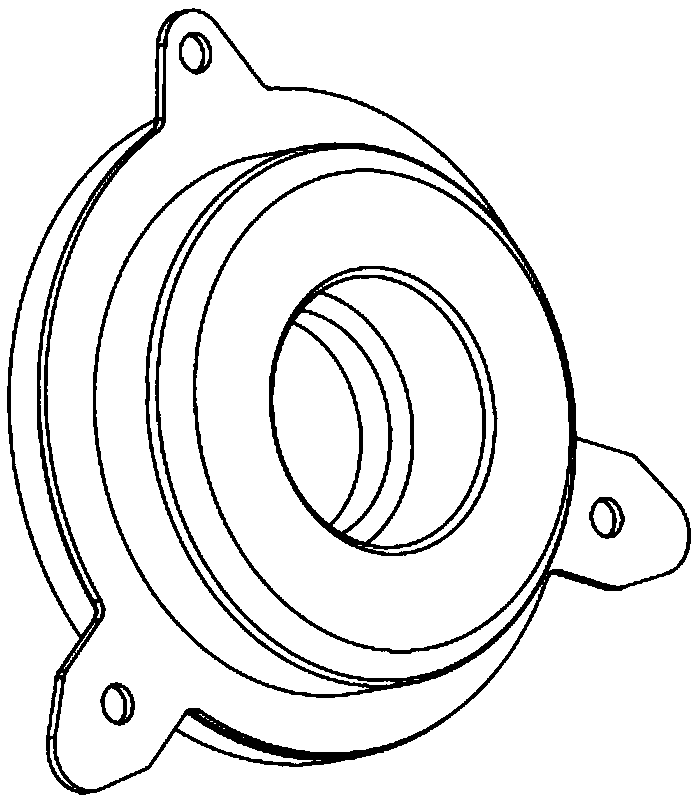

[0030] This implementation provides a image 3 Endshields for motors shown, including sheet metal brackets (eg figure 1 shown) and plastic BMC case (such as figure 2 shown). The plastic-encapsulated BMC housing includes a housing bottom 21 and a bearing chamber 22, and the bearing chamber 22 is directly injection molded from BMC material. Three curved waist-shaped through-holes 11 are arranged on the sheet metal bracket with the central axis as the center and along the circumference. It should be noted that the present invention has no special requirements on the number and shape of the through-holes 11 , and this embodiment only uses three curved waist-shaped through-holes 11 as an example for illustration. The sheet metal bracket is injection molded between the bottom 21 of the housing and the bearing chamber 22 , and the molding compound is connected back and forth through the through hole 11 .

[0031] Preferably, in order to improve the compactness and effectiveness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com