Anti-electric erosion grounding device for variable frequency motor bearings

A frequency conversion motor and grounding device technology, which is applied to the connection with the grounding device, electromechanical device, motor generator connector, etc. and other problems, to achieve the effect of long service life, low resistivity and simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

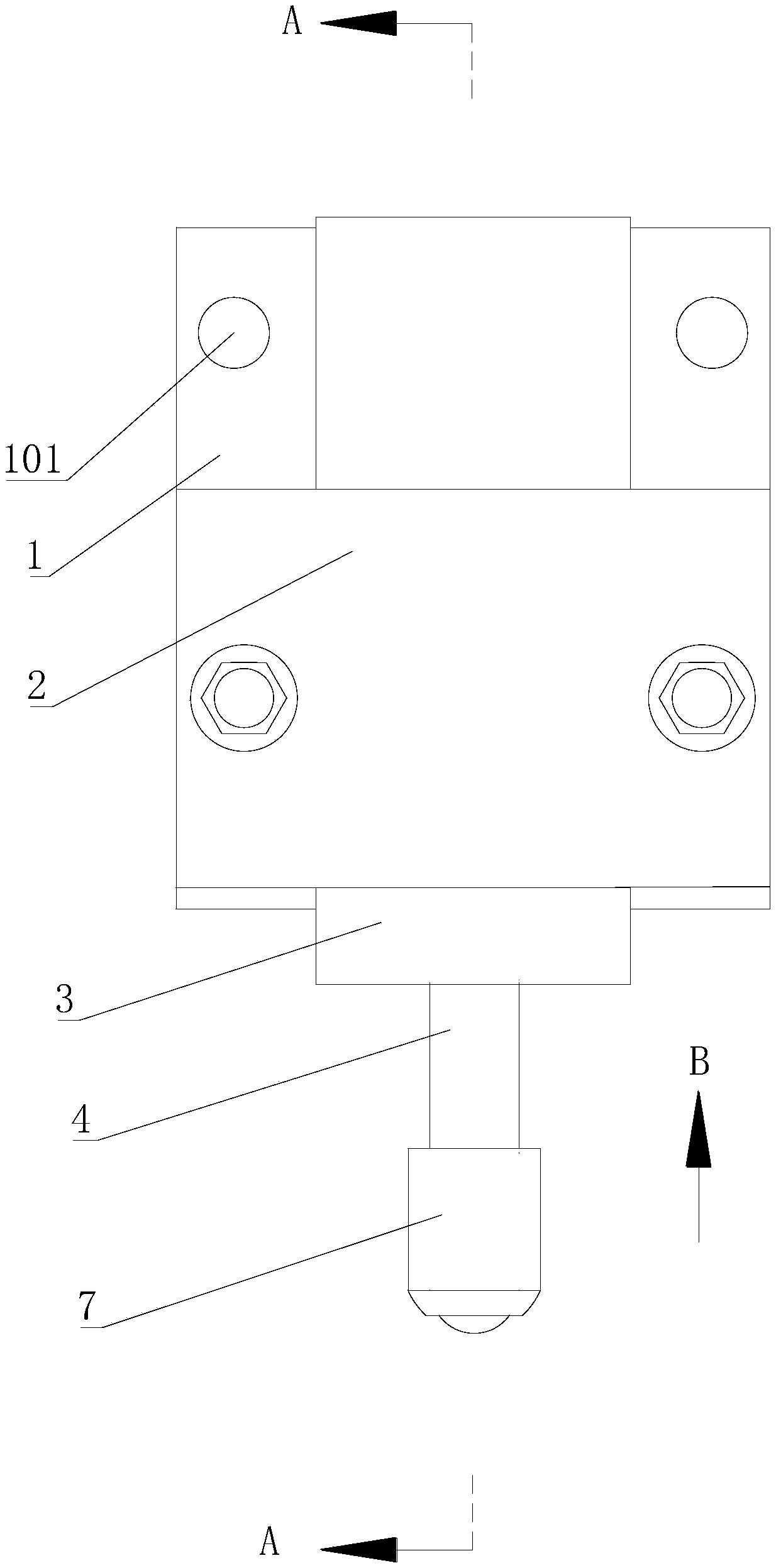

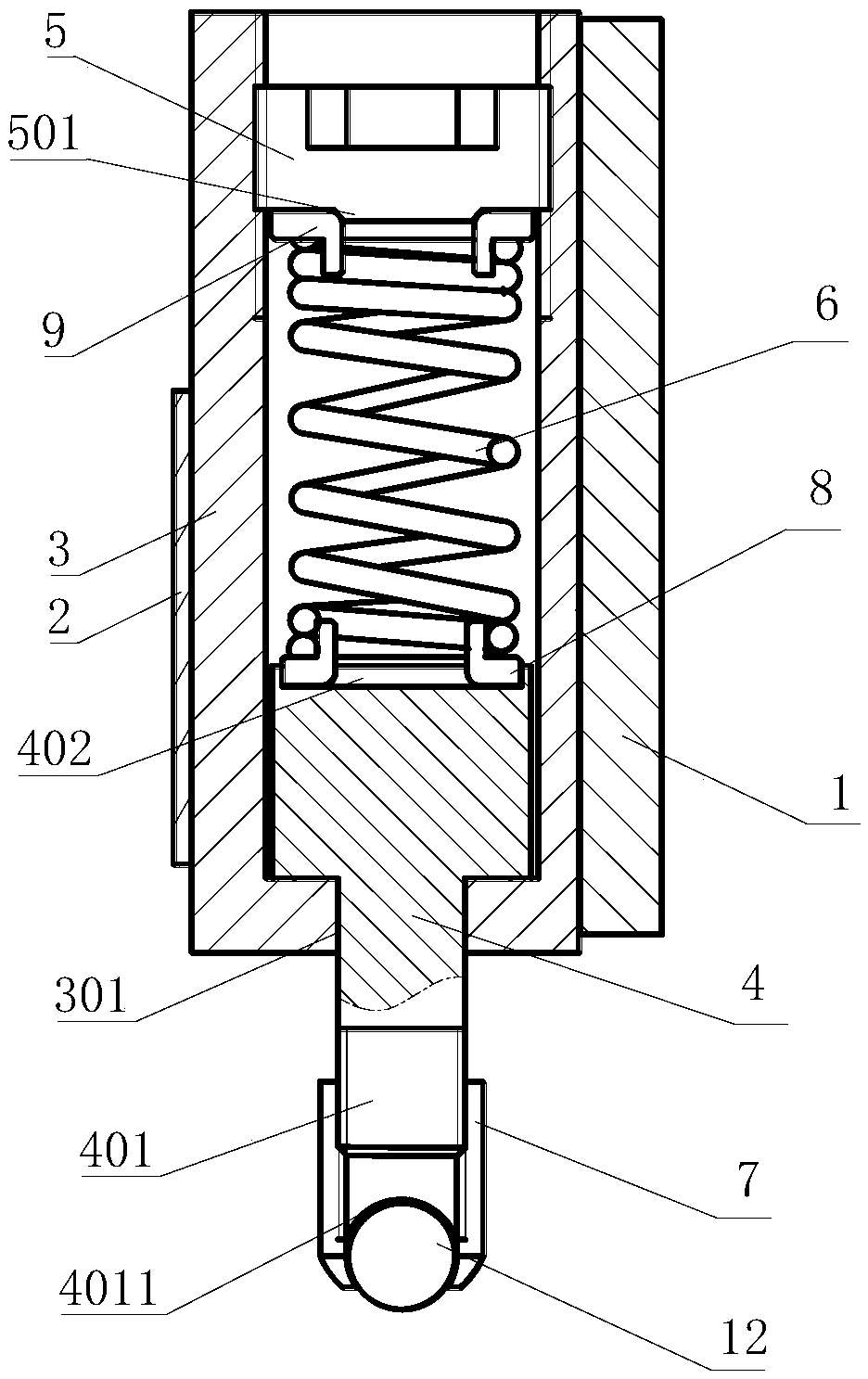

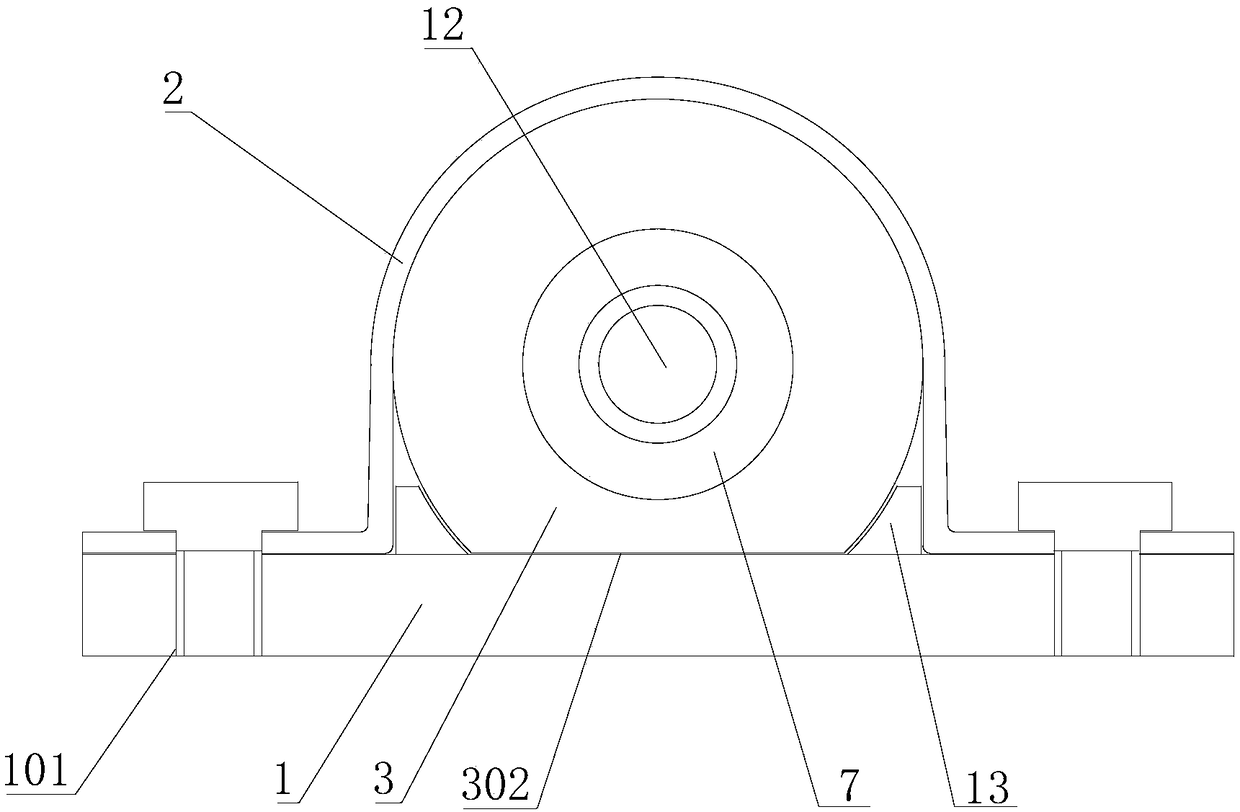

[0026] like Figure 1-4 As shown in the figure, the anti-electrical corrosion grounding device of the variable frequency motor bearing of the present invention includes a U-shaped cylinder 3, and the bottom of the U-shaped cylinder 3 is provided with a through hole 301; the U-shaped cylinder 3 is provided with a stepped shaft 4 inside, The small end 401 of the stepped shaft 4 protrudes from the through hole 301, and the stepped surface is in contact with the bottom of the U-shaped cylinder 3; There is a steel ball 12 between the ends 401, and part of the steel ball 12 is exposed from the outlet on the ball limit sleeve 7; A spring 6 is provided between the head 5 and the stepped shaft 4; it also includes a flat base 1, and the U-shaped cylinder 3 is fixed on the flat base 1 through an arched compression piece 2 screwed with the flat base 1; The flat base 1 is also provided with bolt mounting holes 101 for fixing it to the end cover 10 .

[0027]The head 4011 of the small end...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap