A position sensorless control method for permanent magnet synchronous motor (PMSM) with forward and reverse speed regulation

A technology of permanent magnet synchronous motor and control method, which is applied to motor generator control, electronic commutation motor control, rotation direction control, etc. Easy-to-implement, low-computation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings.

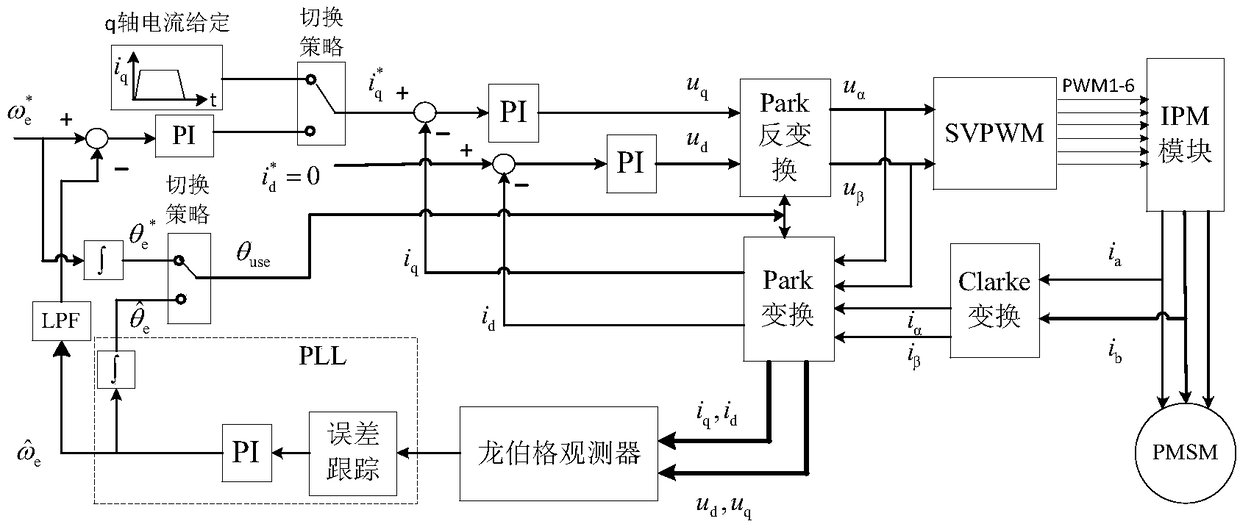

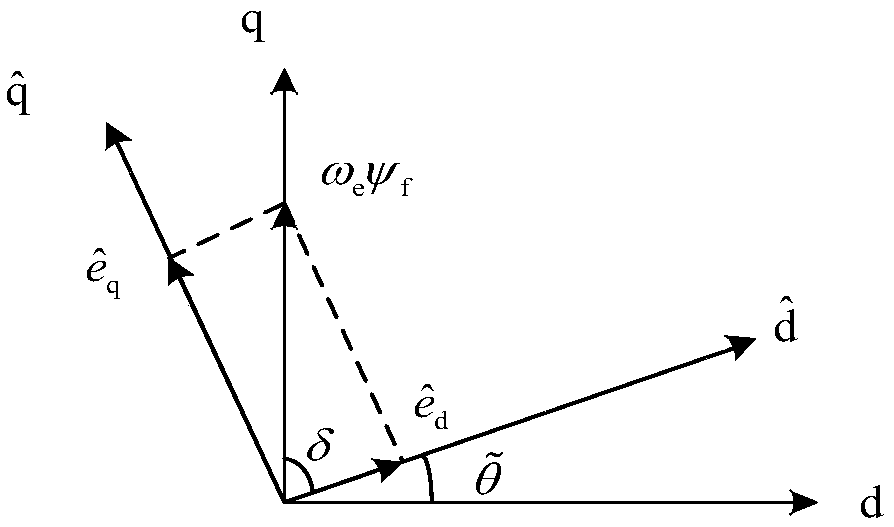

[0050] refer to Figure 1 to Figure 7 , a position sensorless control method for a permanent magnet synchronous motor with forward and reverse speed regulation, comprising the following steps:

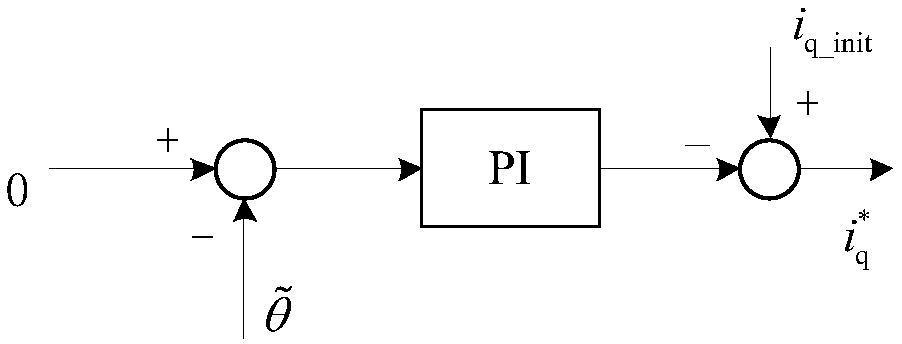

[0051] 1). The I / F start-up control strategy, whose core is to generate a rotating current vector whose frequency gradually increases and whose amplitude follows a given value, is divided into a pre-positioning stage and an acceleration start-up stage:

[0052]1.1). In the pre-positioning stage, a current with a sufficient amplitude is given to the quadrature-axis (q-axis), while the current on the direct-axis (d-axis) is set to zero, and the given position is 270 degrees (The full text is in electrical angles). In this way, the rotor north pole can be positioned on the α-axis. It should be noted that positioning needs to last for a period of time to ensure successful positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com