Dedusting device for leather processing

A dust removal device and leather technology, which is applied in the fields of removing smoke and dust, mechanical treatment of leather surface, raw leather/leather/fur manufacturing equipment, etc. , reduce pollution, strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

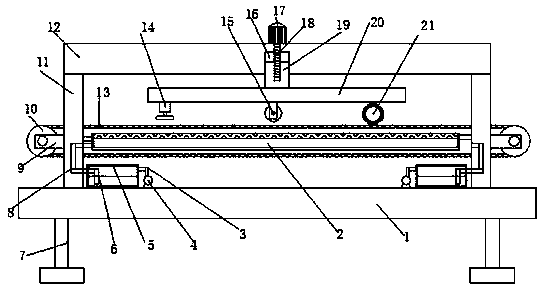

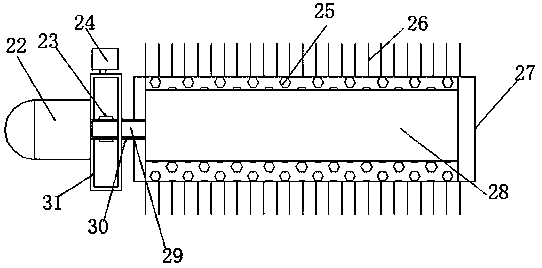

Embodiment 1

[0022] see Figure 1~2 , in an embodiment of the present invention, a dust removal device for leather processing includes a workbench 1, legs 7 are provided on both sides of the lower end of the base 1, a mounting plate 12 is provided above the base 1, and the lower end of the mounting plate 12 is supported on both sides by The plate 11 is connected and fixed with the workbench 1, and a transmission belt 10 is arranged between the installation plate 12 and the workbench 1, and the two ends of the transmission belt 10 are connected and fixed with the support plate 11 through the fixing rod 9, and the belt surface of the transmission belt 10 is evenly distributed Ventilation holes 13 are arranged, and an air suction plate 2 is arranged between the upper and lower belt surfaces of the conveyor belt 10, and air intake holes are evenly distributed on the upper end surface of the air suction plate 2. 11 is connected and fixed, and the left and right sides of the suction plate 2 are ...

Embodiment 2

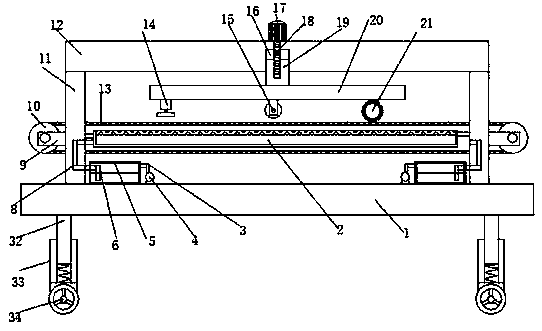

[0027] see image 3 , the difference from Embodiment 1 is that the support leg 7 is replaced by a buffer mechanism, the buffer mechanism includes a buffer leg 32 arranged below the workbench 1, a buffer sleeve 33 is provided on the sliding sleeve at the lower end of the buffer leg 32, and the buffer sleeve 33 The interior is provided with a buffer spring, and the buffer spring 33 connects the buffer leg 32 with the buffer sleeve 33, and the lower end of the buffer sleeve 33 is a roller for convenient device handling, and the roller is a self-locking roller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com